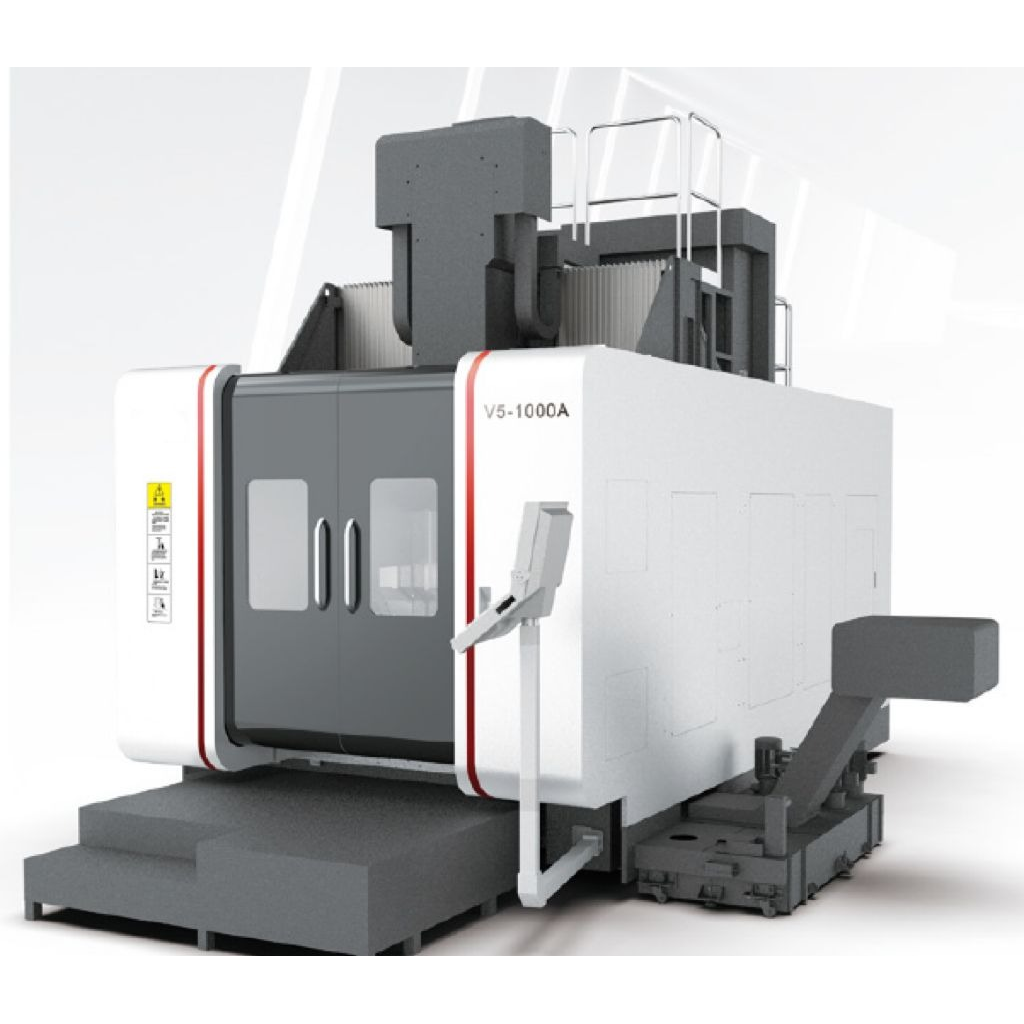

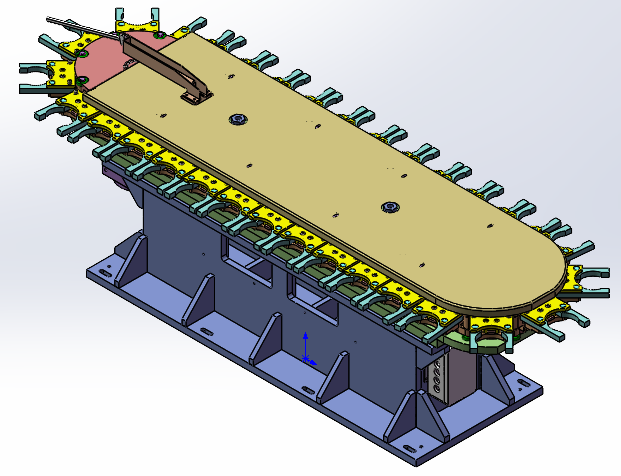

V5-1000A 5-axis machining centre

Mashanu-Axis Vertical Machining Center

Iyo V5-1000A shanu-axis machining centre inotora yakagadzikana yakavharwa gantry chimiro uye ine yakajairwa yemagetsi spindle, maviri-axis yakananga-drive CNC turntable uye yakachinjika cheni servo chishandiso magazini. Inogona kuona yakakwirira-kumhanya, yakakwirira-chaiyo, uye inoshanda machining ezvikamu zvakaoma. Inoshandiswa zvakanyanya muKugadzira kutsva kwemotokari dzesimba, kubhururuka kwakabatana mablisks, steam turbine impellers, molds nezvimwe zvigadzirwa.

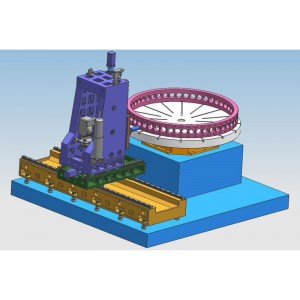

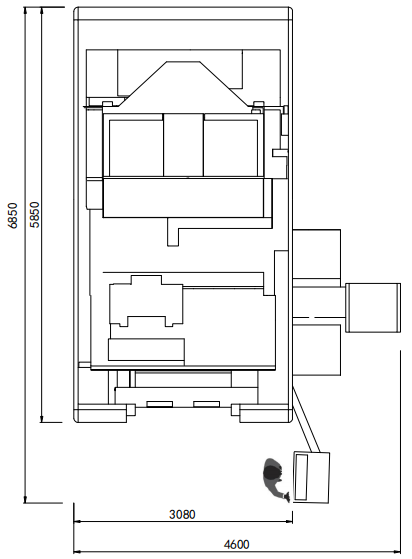

1. Kurongeka kwese kwemuchina

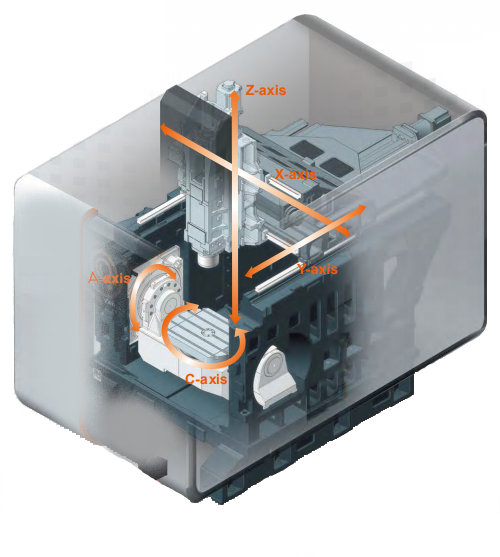

Iyo V5-1000A shanu-axis machining Center inotora yakagadzikana gantry chimiro, iyo koramu yakamisikidzwa pachigadziko, danda rinofamba kureba richitevedza mbiru (Y kutungamira), siraidhi ndiro inofamba yakatarisana nedanda (X kutungamira), uye iyo musoro wemusoro unofamba wakatwasuka uchitevedza ndiro ine siraidhi (Z nzira) . Iyo bhenji yebasa inotora iyo yakazvigadzira yakananga-kutyaira kiredhiti chimiro, uye akasiyana maratidziro ekuita asvika padanho repamusoro renyika.

2. Kudyisa system

Iyo X, Y, Z mbezo dzinotora kusimba kwepamusoro-soro, yakakwirira-chaiyo roller mitsara madhiraivha uye yakakwirira-performance bhora screws, ine yakaderera dynamic uye static friction, high senitivity, yakaderera vibration pakumhanya kwakanyanya, hapana kukambaira nekumhanya kwakaderera, nzvimbo yakakwirira. kunyatsoita, uye yakanakisa servo drive kuita.

X, Y, Z axis servo motors dzakabatana nepamusoro-soro bhora screws kuburikidza nemadhiraivha chaiwo, ane flexible feeding, chaiyo chinzvimbo uye yakanyanya kutapurirana chaiyo.

Iyo Z-axis servo mota ine brake basa. Panyaya yekutadza kwemagetsi, inogona kubata otomatiki brake kuti ibate shaft yemota zvakasimba kuti isatenderere, iyo inoita basa mukuchengetedza kuchengetedza.

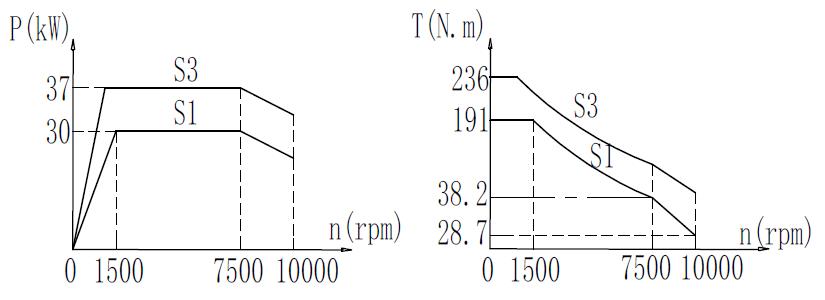

3. Electric spindle

Iyo mota ine spindle inotora yakazvimisikidza BT50 motorized spindle (HSKA100 motorized spindle ndeye sarudzo), uye iyo yekupedzisira inoshongedzerwa nemhete yekupfapfaidza yakabatana kuti itonhodze chishandiso. Iyo ine mabhenefiti ekumhanya kwakanyanya, yakanyanya kurongeka, yakakwirira simba mhinduro, nezvimwewo, uye inogona kuona isina nhanho yekumhanya mutemo, yakavakirwa-mukati-yakanyanya-encoder, inogona kuwana yakananga yekumira uye yakaomesesa tapping.

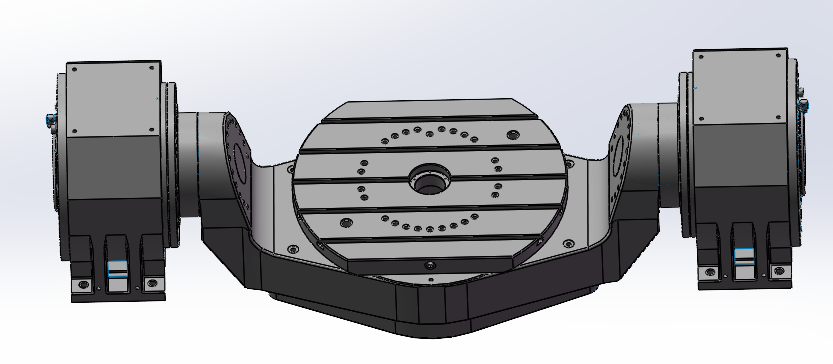

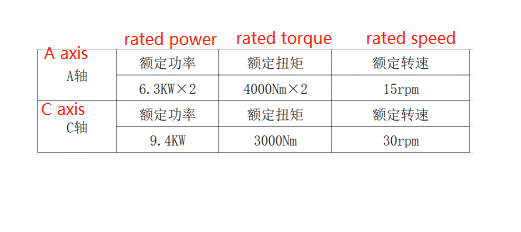

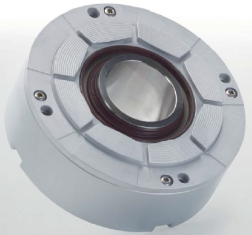

4. Turntable

Iyo yakazvimisikidza mbiri-axis yakananga-drive cradle turntable yakashongedzerwa nepamusoro-chaiyo absolute encoder uye inotonhodzwa neinotonhorera yemvura patembiricha isingaperi. Iine zvakanakira kusimba kwepamusoro, kurongeka kwepamusoro, uye yakakwirira simba remhinduro. Iyo worktable inotora 5-18mm radial T-slots, uye inotenderwa mutoro i2000kg (yakagoverwa zvakaenzana)

5. Magazini yemidziyo

Magazini yezvishandiso inotora BT50 yakatwasuka ketani servo chishandiso magazini, iyo inogona kugamuchira makumi matatu maturusi.

6. Yakanyatsovharwa loop mhinduro system

X, Y, Z mutsara matemo ane HEIDENHAIN LC195S absolute value grating mutongi; A uye C matafura anotenderera ane HEIDENHAIN RCN2310 absolute value angle encoder kuti uwane yakazara yakavharika-loop mhinduro yemademo mashanu ekudyisa, kuve nechokwadi chekuti muchina une chaiyo chaiyo uye yakanyanya Kuchengeta.

7. Kutonhora uye pneumatic system

Yakashongedzerwa nehombe yekutonhora yekuyerera pombi uye tangi remvura kuti ipe kutonhora kwakakwana kune maturusi uye workpieces. Iyo headstock yekupedzisira kumeso yakashongedzerwa neinotonhorera nozzles, iyo inogona kudzorwa neM kodhi kana control panel.

Yakashongedzerwa neinotonhorera yemvura yekugara ichitonhora tembiricha, kuve nechokwadi chekuti electric spindle uye yakananga drive turntable zviri mumamiriro ekushanda akanaka uye anogona kumhanya nemazvo kwenguva yakareba.

Iyo pneumatic system inotora zvinhu zvepneumatic zvekusefa, uye inoona mabasa ekuchenesa uye kuvhuvhuta tepi gomba re spindle, kuchengetedza chisimbiso chemhepo cheiyo spindle bearing, nekufuridza nekuchenesa mutongi wegiya.

8. Centralized lubrication system

Iyo siraidhi block yenjanji yekutungamira uye nati yebhora screw zvese zvakazorwa negirizi yakatetepa, uye iyo lubrication inopihwa nguva nenguva uye nehuwandu kuti ive nechokwadi chekunyatso uye kugadzikana kwebhora screw uye gwara renjanji.

9. Oiri uye gasi lubrication system

Iyo electric spindle ine oiri inotengeswa kunze kwenyika uye gasi lubrication mudziyo, iyo inogona kuzara nekuzora nekutonhodza spindle. Iyo sensor inogona kupa abnormal lubrication alarm, iyo inogona kunyatso shuwa kuti spindle inogona kushanda yakadzikama pakumhanya kwakanyanya kwenguva yakareba.

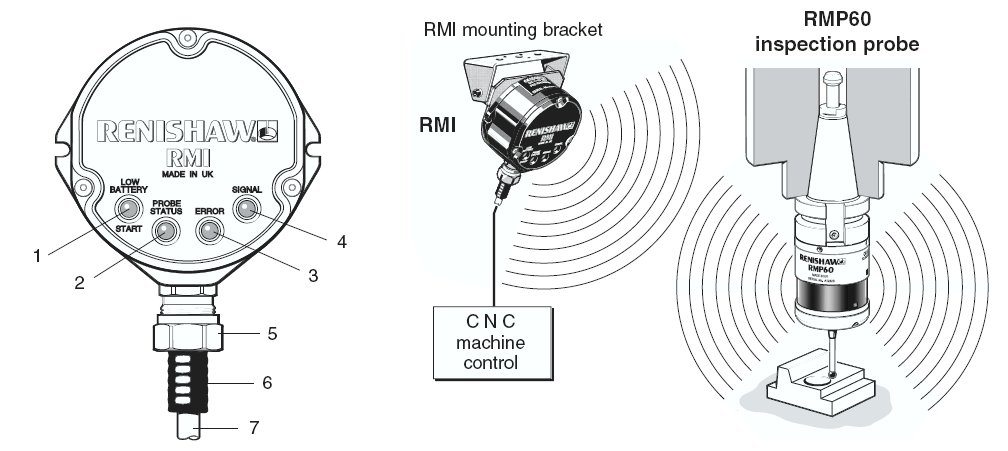

10. Workpiece measuring system

Muchina uyu wakashongedzerwa neRenishaw RMP60 redhiyo probe, inoshandiswa pamwe chete neRMI inogamuchira, iyo frequency yekushanda ndeye 2400 MHz kusvika 2483.5 MHz, kuyerwa kwenzira imwe chete kudzokororwa kuri pasi kana kuenzana ne1um (480mm/min kuyerwa kwekumhanya, uchishandisa a 50mm penzura), uye tembiricha yekushanda inoshanda i5°C kusvika 55°C.

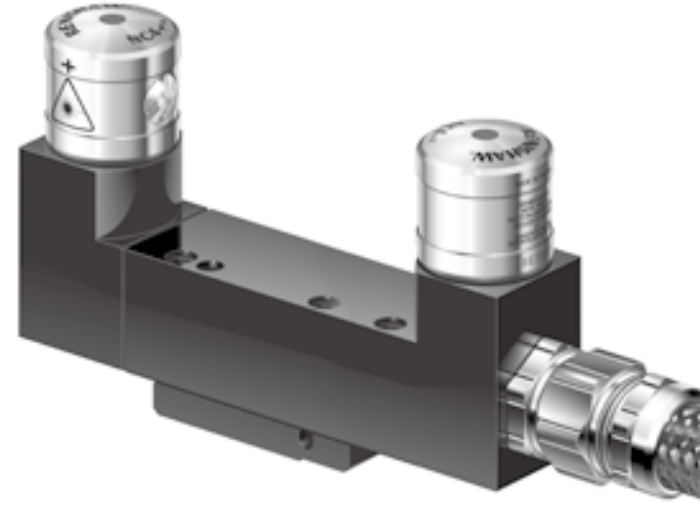

11. Chishandiso chekuyera hurongwa

Muchina uyu wakashongedzerwa neRenishaw NC4 laser chishandiso setter, kuyerwa kudzokororwa kuri ± 0.1um, uye tembiricha yekushanda i5 ° C kusvika 50 ° C.

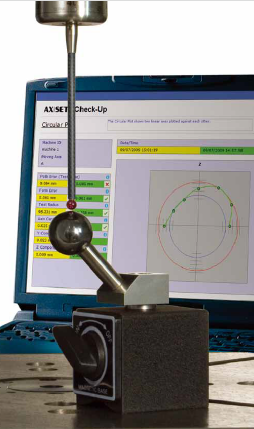

12. Five-axis precision calibration basa

Muchina uyu wakashongedzerwa neRenishaw's AxiSet Check-Up Rotary Axis Line Checker kit, yakapetwa neyeworkpiece yekuyera system RMP60, inoita kuti vashandisi vemuchina vaone nekukurumidza uye nemazvo mamiriro ematemo anotenderera uye kuona matambudziko anokonzerwa nekupisa uye hunyoro shanduko, kudhumhana kwemuchina kana. kubvaruka. matambudziko, anogona kukurumidza kugadzirisa uye kutsvaga macheki ekuita, bhenji uye kutarisa kuti michina yakaoma inochinja sei nekufamba kwenguva.

13. kudzivirira muchina

Muchina uyu unotora chivharo chakavharirwa zvizere chekudzivirira chinosangana nemaitiro ekuchengetedza kudzivirira kupfachuka kwezvinotonhorera uye machipisi, kuve nechokwadi chekushanda kwakachengeteka, uye kuve nechitarisiko chinofadza. Iyo X-direction yemuchina ine chivharo chekudzivirira chekudzivirira, chinogona kudzivirira zvinobudirira njanji uye bhora screw.

14. machine kushanda mamiriro

(1) Simba rekushandisa: 380V±10% 50HZ±1HZ matatu-chikamu chinochinjanisa ikozvino

(2) Ambient tembiricha: 5℃-40℃

(3) Kupisa kwakanyanya: 20℃±2℃

(4) Hunyoro hunyoro: 20-75%

(5) Mhepo sosi kudzvanywa: 6±1 bar

(6) Mhepo inoyerera inoyerera: 500 L / min

15. Basa rekutanga reCNC system

Siemens 840Dsl.730 CNC system configuration

| Item

| Zita

| Mashoko

|

| System mabasa | Minimum pulse yakaenzana | Linear axis 0.001 mm, akisi inotenderera 0.001° |

| Chiyero chekudya paminiti / shanduko | ||

| Kudyisa uye kukurumidza kufamba | ||

| Feedrate override 0~120% | ||

| Spindle speed limit | ||

| Spindle inogara ichikurumidza kucheka | ||

| Spindle monitoring | ||

| Spindle override 50~120% | ||

| Spindle speed display | ||

| FRAME | Ziva kurongeka kweshanduko system uye bevel machining | |

| Yakananga / isina kunanga kuyerwa system switching | ||

| Tarisa-mberi basa kana kutarisa-mberi basa | ||

| Lead screw pitch error compensation | ||

| Measurement System Kukanganisa Muripo | ||

| Quadrant Error Muripo | ||

| Backlash compensation | ||

| Tool management | ||

| Hardware Configuration | Nhamba yekutonga masanhu | X, Y, Z, A, C shanu dzinobatanidza matemo uye imwe hombe akisi |

| Panguva imwe chete kutonga kwenhamba yemasanhu | X, Y, Z, A, C shanu-axis linkage | |

| zita reaxis | X, Y, Z, A, C, SP | |

| monitor | 15" LCD kuratidza mavara, kuratidza mavara muchiChinese/Chirungu | |

| Operation panel | OP015 yakazara basa CNC kiibhodhi | |

| murume-muchina kutaurirana interface | Standard configuration TCU | |

| Machine control panel | SINUMERIK MCP 483C PN control panel, 50 mechanical keys ine LED, ine PROFINET, Industrial Ethernet interface. | |

| Handheld operating unit | ||

| Standard keyboard interface | ||

| Ethernet interface | Yakabatanidzwa paNCU (yakavhurika workshop networking basa) | |

| USB port | 3 x 0.5 A USB yakabatanidzwa paTCU | |

| PLC chirongwa | PLC317-3PN/DP | |

| Interpolation function | Kudya kumbomira | |

| kucheka shinda | ||

| Kucheka panguva imwe chete | ||

| Tatu-kuronga mutsara kududzira | ||

| Kupindirana kwemaviri-kuronga kutenderera kwedenderedzwa | ||

| Helical interpolation | ||

| Kudzvanya / Kubata kwakaoma | ||

| programming | Kutekenyedza/kutenderedza zvakanyanya | |

| program editor | Teerera neDIN66025 yakajairwa, ine-yepamusoro-nhanho yemutauro zvirongwa | |

| Absolute kana kuwedzera purogiramu | ||

| Mushandisi variable, settable | ||

| Chirongwa chinosvetuka nemapazi | ||

| macro program | ||

| Rongedza shanduro yehurongwa uye kutenderera | ||

| Panguva imwe chete kuronga uye kugadzira | ||

| Murairo wepurogiramu yekudzokera kunzvimbo yereferensi | ||

| Contour programming uye canned cycle programming | ||

| Mirroring uye scaling | ||

| kusarudzwa kwendege | ||

| Workpiece coordinate system | ||

| Kuchera uye kugaya makoni kutenderera | ||

| Zero offset | ||

| block search | ||

| Chirongwa chekutsvaga nhamba | ||

| Background editing | ||

| kudzivirira chirongwa | ||

| Sarudza purogiramu nedhairekitori | ||

| Arithmetic uye trigonometric mabasa | ||

| Kuenzanisa uye zvine musoro mashandiro | ||

| Mashanu-axis machining software package | Shanu-axis shanduko; shanu-axis tool muripo; kutenderera basa kutenderedza mudziyo wekushandisa (RTCP) | |

| Basa rekuchengetedza kuchengetedza | Programmable machining nzvimbo miganhu | |

| Chirongwa chekuedza basa | ||

| emergency stop | ||

| Software limit monitoring | ||

| Contour monitoring | ||

| Kuona kudhumhana kweContour | ||

| Static monitoring | ||

| Kutariswa kwenzvimbo | ||

| speed monitoring | ||

| Kugadziriswa kwenzvimbo kurambidzwa | ||

| torque limit | ||

| Chengetedzo inoshanda Clock yekutarisa kuyerwa maseketi, kuwandisa, bhatiri, voltage, ndangariro, muganhu switch, fan monitoring. | ||

| Operation nzira | AUTOMATIC | |

| JOG (manual) kugadzirisa | ||

| Handwheel operation | ||

| MDA manual data entry | ||

| NC uye PLC diagnostics ine mavara kuratidza, skrini saver | ||

| kushanda uye kuratidza | Self-diagnostic basa kuratidza | Kusanganisira REF modhi, incremental mode (x1, x10, x100) |

| Yazvino nzvimbo inoratidza | ||

| Graphical display | ||

| chirongwa chekuratidzira | ||

| chirongwa kukanganisa kuratidza | ||

| Operation kukanganisa kuratidza | ||

| Chaiye chekucheka speed display | ||

| Chinese neChirungu menyu kuratidza | ||

| Alarm information display | ||

| Maseti akawanda eM-code yekuraira seti | ||

| Tsigira PROFINET bhazi data kutamiswa | ||

| data kutaurirana | USB port | NC data, PLC data uye zvirongwa zvinotsigirwa kuU dhisiki yekupinza uye yekubuda data |

| Ethernet data kutumira | Kuburikidza neEthernet interface |

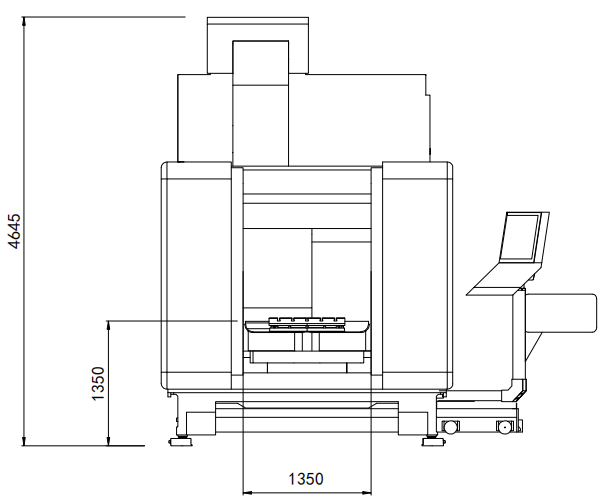

Main parameter

| Item | Zvinotsanangurwa | Unit | |||

| workbench

| kushanda dhesiki saizi | φ1000×800 | mm | ||

| inobvumirwa mutoro mukuru | 2000 | kg | |||

| T-slot size | 5×18 | 个×mm | |||

| processing scope

| X axis | 1150 | mm | ||

| Y axis | 1300 | mm | |||

| Z axis | 900 | mm | |||

| A-axis | -150+130 | ° | |||

| C axis | 360 | ° | |||

| Distance from spindle end face to work table | Max | 1080 | mm | ||

| Min | 180 | mm | |||

| Spindle

| Koni gomba | BT50 | |||

| Rated speed | 1500 | r/min | |||

| kukurumidza kumhanya | 10000 | ||||

| Kuburitsa torque S1/S6 | 191/236 | Nm | |||

| Spindle mota simba S1/S6 | 30/37 | kW | |||

| Axis

| famba nokukurumidza | X axis | 25 | m/min | |

| Y axis | 25 | ||||

| Z axis | 25 | ||||

| Turntable maximum speed | A-axis | 15 | rpm | ||

| C axis | 30 | rpm | |||

| X/Y/Z axis mota simba | 3.1/4.4/2 | kW | |||

| A/C axis Mota simba | 6.3 *2/ 9.4 | kW | |||

| A-axis | Rated torque | 4000 × 2 | Nm | ||

| C axis | Rated torque | 3000 | Nm | ||

| huwandu hwekudya | X/Y/Z | 25 | m/min | ||

| A/C | 15/30 | rpm | |||

| Tool magazine

| Chishandiso chemagazini fomu | horizontal | |||

| chombo chekusarudza nzira | Nzira mbiri dziri pedyo sarudzo yezvishandiso | ||||

| Tool magazini kukwanisa | 30 | T | |||

| Maximum tool kureba | 400 | mm | |||

| Maximum tool uremu | 20 | kg | |||

| Maximum cutter musoro dhayamita | yakazara nemapanga | φ125 | mm | ||

| Pedyo nemudziyo usina chinhu | φ180 | mm | |||

| chinzvimbo nemazvo | Executive mwero | GB/T20957.4 (ISO10791-4) | |||

| X-axis/Y-axis/Z-axis | 0.008/0.008/0.008 | mm | |||

| B axis / C axis | 8″/8″ | ||||

| dzokorora chinzvimbo nemazvo | X-axis/Y-axis/Z-axis | 0.006/0.006/0.006 | mm | ||

| B axis / C axis | 6"/6" | ||||

| Machine uremu | 33000 | kg | |||

| simba rose remagetsi | 80 | KVA | |||

| saizi yemuchina | 7420×4770×4800 | mm | |||

Configuration List

Standard

|

| 1. Zvikamu zvikuru (kusanganisira hwaro, koramu, danda, siraidhi ndiro, spindle bhokisi) |

| 2. X, Y, Z matatu-axis feed system | |

| 3. Cradle type turntable AC1000 | |

| 4. Mushonga wemagetsi | |

| 5. Electrical control system (kusanganisira magetsi emagetsi, magetsi module, servo module, PLC, shandiso yepaneru, kuratidza, inobatwa nemaoko, electric cabinet air conditioner, nezvimwewo) | |

| 6. Hydraulic system | |

| 7. Pneumatic system | |

| 8. Centralized lubrication system | |

| 9. Mvura inotonhorera | |

| 10. Chip conveyor, tangi remvura, chip collector | |

| 11. Grating mutongi | |

| 12. Rail protection cover | |

| 13. muchina chose chinodzivirira chivharo | |

| 14. Workpiece yekuyera system | |

| 15. Chimbo chekugadzirisa chiridzwa | |

| 16. Five-axis precision calibration basa | |

|

| 1. 1 chitupa chekuenderana 2. Packing list 1 kopi 3. 1 seti yemuchina wechina (electronic version) 4. data backup yemuchina 1 set (U disk) 5.840D alarm diagnostic manual 1 set (electronic version)/828D diagnostic guide 1 kopi (electronic version) 6.840D milling operation manual 1 kopi (electronic version)/828D operation manual 1 kopi (electronic version) 840D programming manual 1 basic part (electronic version) / 828D programming manual 1 (electronic version) |

| Item | Brands |

| X/Y/Z axis mota uye kutyaira | Siemens, Germany |

| simba cheni | germany igus |

| screw bear | Japan NSK/NACHI |

| Linear Guides | Schneeberg, Germany |

| Tool magazine | Okada |

| reducer | STOBER, Germany |

| Centralized lubrication | Japani |

| Ball screw | SHUTON, Spain |

| Pneumatic Components | Japan SMC |

| Electric cabinet air conditioner | China |

| mvura inotonhorera | China |

| grating mutongi | HEIDENHAIN, Germany |

| Workpiece measuring system | Renishaw, UK |

| Tool yekuyera system | Renishaw, UK |

| Pats nemuchina | Zvinotsanangurwa | Quantity |

| Muchina metiresi iron |

| 8 seti |

| Anchor bolts |

| 8 seti |

| zvindori | M30 | 2 zvidimbu |

| zvindori | M36 | 2 zvidimbu |

| suspenders |

| 1 set |

| Allen key | 10 | 1 |

| Allen key | 12 | 1 |

| Allen key | 14 | 1 |

| Allen key | 19 | 1 |

| Z-axis gomo |

| 1 |

| X-axis gomo |

| 1 |

| Y-axis kugadzirisa |

| 1 |

Thanks Nekuteerera Kwako!