Center Drive lathe For Thin-walled chubhu

Thin-walled Tube uye Tube Zvikamu

Technology Solution

1.Kuongorora kwekugadzirisa kwekugadzirisa zvikamu zvakatetepa-walled cylindrical

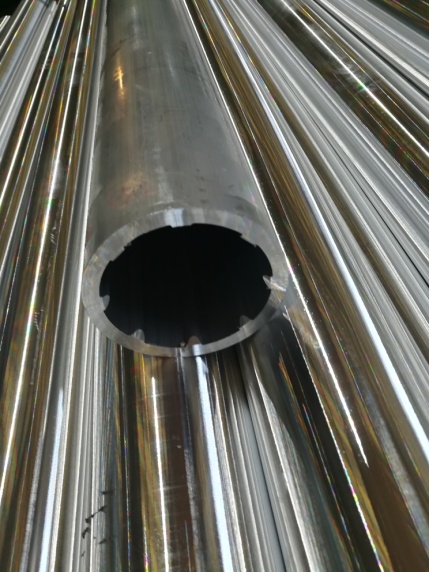

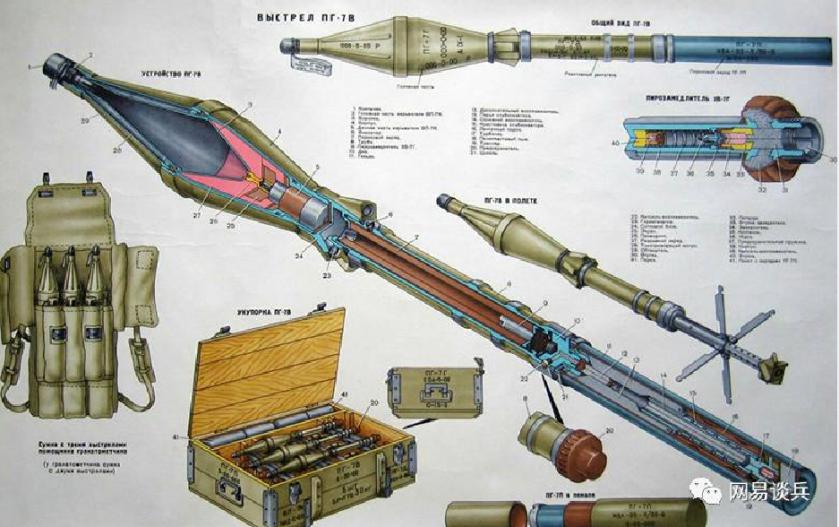

Thin-walled chubhu uye chubhu zvikamu zvagara iri nzvimbo yakaoma mukugadzira. Semuyenzaniso: iyo perforating pfuti muviri weiyo perforating michina inoshandiswa mukuchera petroleum muchina, mukati nekunze goko redownhole shock absorber, mukati nekunze goko repombi yemafuta anodzivirira, dhiramu rekudhinda remichina yekudhinda, dhiramu rinotenderera machira emuchina, muchina wekutapurirana Conveyor roller, kuchera pasi-pagomba uye midziyo yekuputika.

Iyo yekunze casing, nezvimwewo, hongu, inosanganisirawo mabhomba emauto kana echivanhu.

1.1Zvakakwana zvikamu

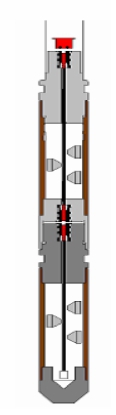

Chimiro chepfuti inoputika: zvikamu zvikuru zvepfuti inoputika muviri wepfuti, musoro wepfuti, muswe wepfuti, mubatanidzwa wepakati, detonation accessory, mhete yekuisa chisimbiso uye chibatiso che cartridge. Izvo zvakakosha kuita zvinodiwa zvepfuti yekupfura. Sechikamu chikuru chinotakura chechimiro chesimba perforator, iyo inonyanya kukosha kuita kwepfuti inoputika isimba rayo remuchina. Chete kana michina yayo yasangana, iyo yakaumbwa simba perforator inogona kuvimbiswa Kugona uye kuchengetedzeka panguva yekudonha kwegomba.

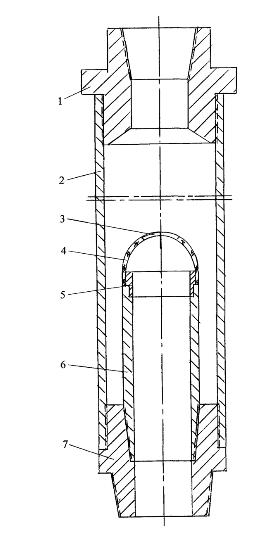

Oiri pombi mudziviriri

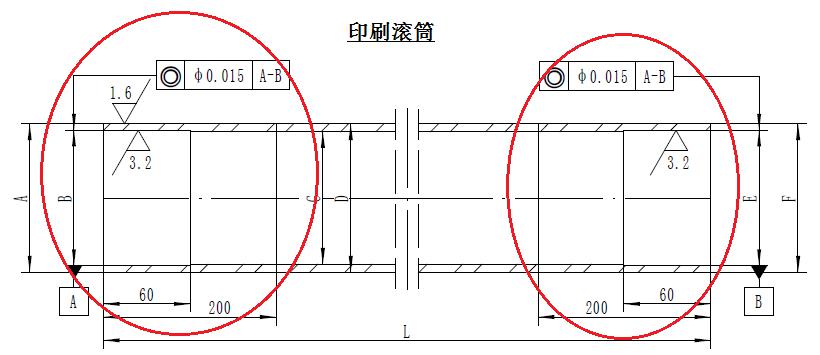

Silinda yekudhinda

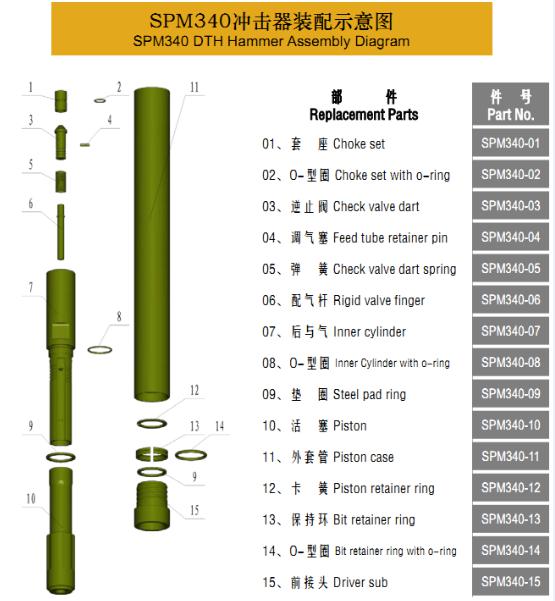

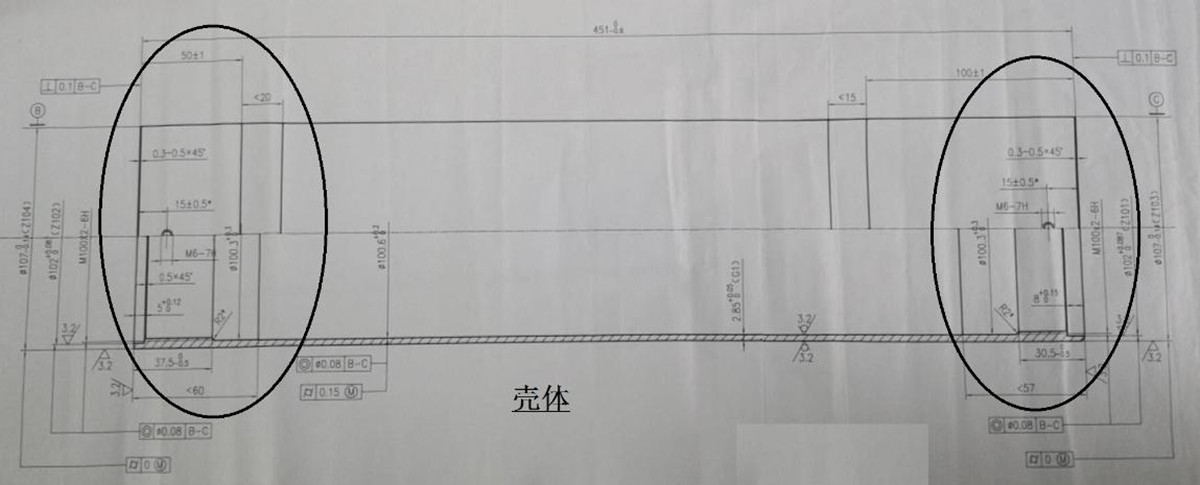

Kuenzanisa kwetsva uye yekare impactor shell processing tekinoroji

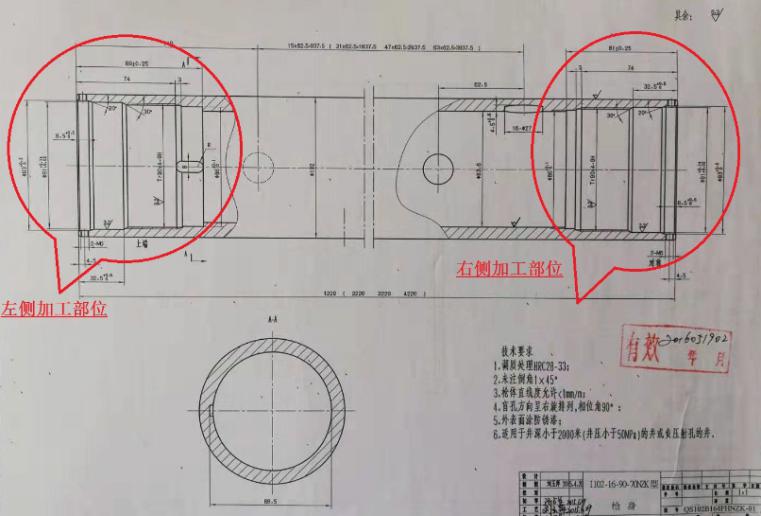

Rudzi urwu rwezvikamu zvine chinhu chimwe chete chakafanana: mapaipi ane madziro akatetepa akaumbwa nekukunguruka kana kuruka anonyanya kugadziriswa kumativi ese maviri, mukati megomba kumira (yekusangana), shinda yemukati megomba (yekubatanidza), denderedzwa rekunze diki, shinda yekunze. kana Zvichidiwa), mukati uye kunze sipes isina chinhu uye chamfer

1.2. Process analysis.

1) Tsika yekugadzirisa tekinoroji:

Kazhinji, imwe mugumo welathe unoshandiswa kusungirira, uye imwe magumo inoshandisa tailstock pamusoro pegomba remukati uye yepakati furemu yemotokari, wobva washandisa furemu yepakati kutsigira, uyezve kufinha buri remukati memugumo uyu. , iyo yekupedzisira chiso chemota, uye machining angangodiwa pakushandura denderedzwa rekunze Zvikamu, kana zvikamu zvinosungirira zvinodiwa pakutendeuka nekutendeuka.

Workpiece U-turn: yemukati tsigiro kana yekunze clamp cylinder body, tailstock inosimbisa iyo workpiece, mota yepakati furemu socket, yepakati furemu rutsigiro, re-boring remukati gomba, mota yekupedzisira kumeso, denderedzwa rekunze.

Kana iyo coaxiality yemakomba emukati pamativi ese ecylinder yakakwira zvishoma, kugadzirisa kunogona kudzokororwa kakawanda.

2) Kushandisa kaviri-kuguma CNC lathe processing tekinoroji:

Kugadziriswa kwezviri pamusoro apa kunogona kupedzwa mune imwe clamping, uye migumo yese inogona kugadziriswa panguva imwe chete, iyo isingangodzikisi huwandu hwematurusi emuchina, asi zvakare inopfupisa kuyerera kwemaitiro uye kubata kwezvinhu, uye inovandudza zvakanyanya kugadzirwa. . Sezvo migumo miviri ichigadziriswa panguva imwe chete, iyo coaxiality yeworkpiece inovimbiswawo zvakavimbika.

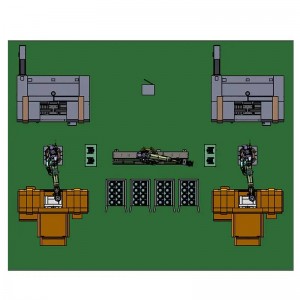

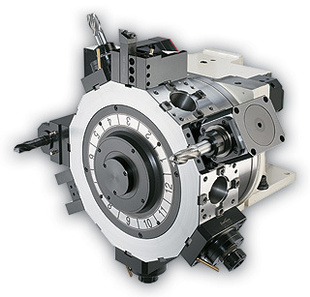

Kunyanya: zvichienderana nehurefu hwechishandiso, imwe kana maviri misoro inogona kushandiswa kusungirira denderedzwa rekunze reworkpiece. Iyo clamping dhayamita uye clamping hupamhi hwemusoro wemusoro unotemwa zvichienderana nedhayamita uye kureba kweiyo workpiece. Maviri 8/12-station rotary turrets Panguva imwe chete inogadzirisa chiso chekupedzisira, mukati megomba uye denderedzwa rekunze kumativi ose maviri. Sezvo nhamba yezvishandiso zvinogona kuiswa zvakakwana, zvinogona kusangana nekamwe-nguva yekugadzirisa zvinodiwa zvezvikamu zvakaoma.

Kana iyo yekunze yekunamatira chikamu chemuchina chishandiso mune ino kutevedzana ichida kugadziriswa, saka shandisa muchina chishandiso kupeta-pamusoro maburi emukati pamativi ese echishandiso kutenderedza kana kukuya denderedzwa rekunze.

Kune zvakare vatengi vanoshandisa grinder isina centre kukuya denderedzwa rekunze pachine nguva, uye vobva vashandisa kaviri-magumo CNC lathe kugadzirisa maburi emukati uye kupedzisa zviso kumagumo ese kune zvinodiwa maitiro.

3) Mhosva dzecylindrical zvikamu zvakagadziriswa nekaviri-kuguma CNC lathes:

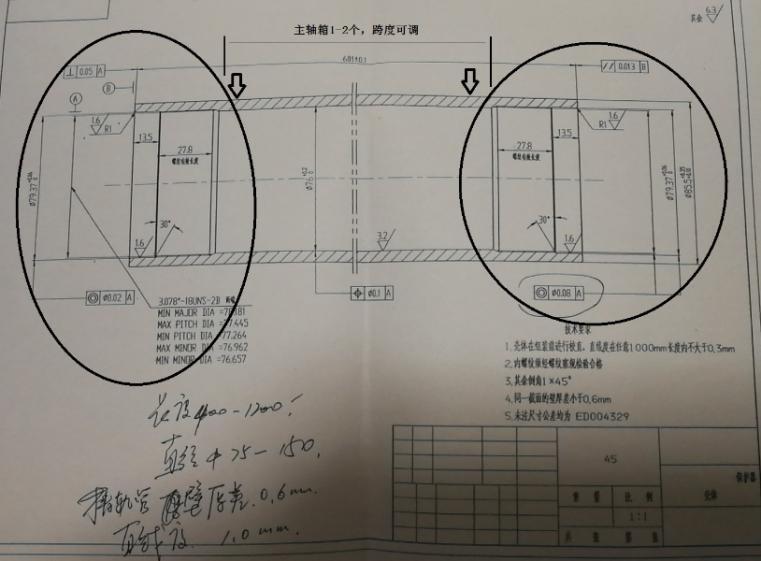

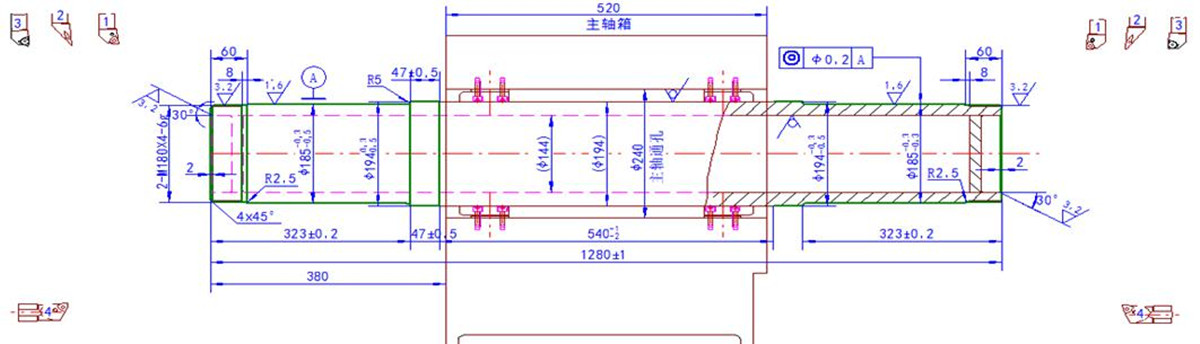

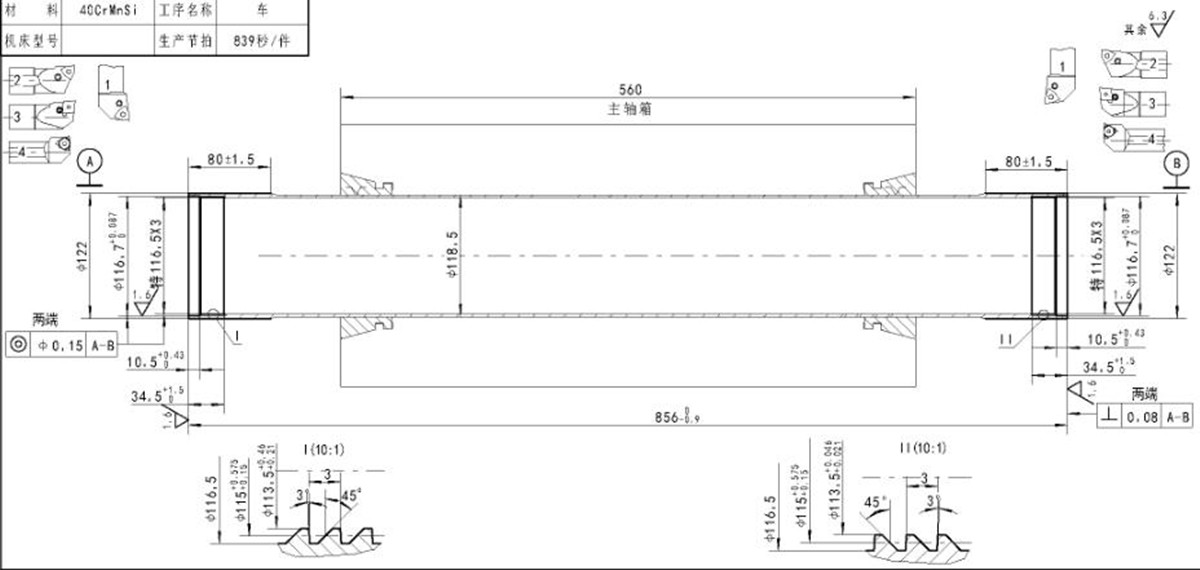

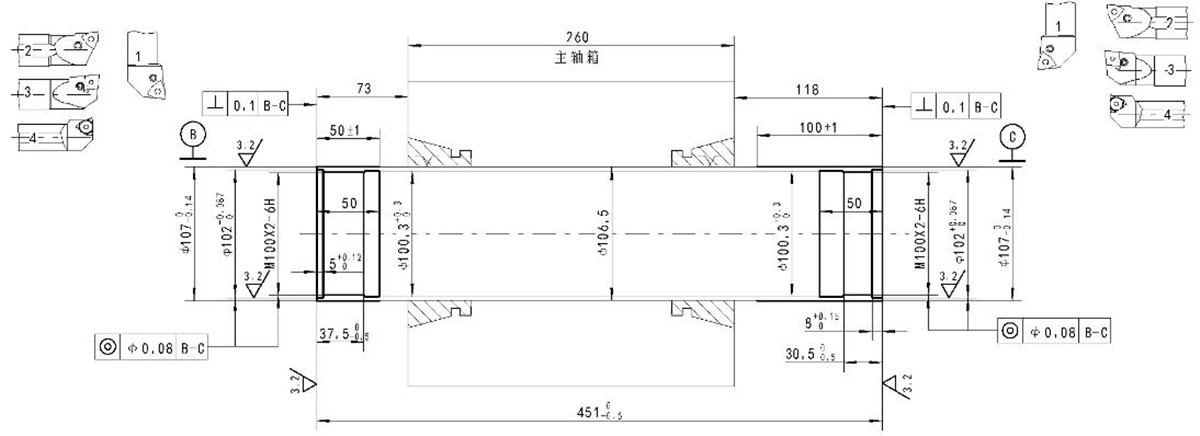

①Kugadzira silinda yemuchina wekudhinda, sarudza SCK208S modhi (uchishandisa kaviri spindle bhokisi).

②Iyo SCK309S modhi (imwe musoro) inoshandiswa kugadzirisa ekisi yepakati pemota.

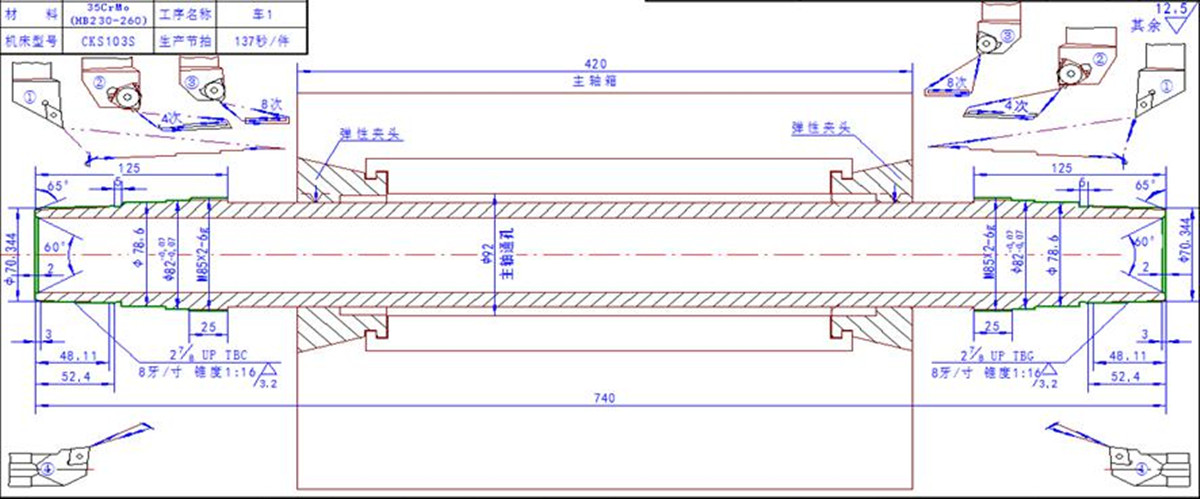

③SCK105S modhi inoshandiswa kugadzirisa mauto akatetepa-akakomberedzwa machubhu.

④Kugadzirisa machubhu echiuto akatetepa-akakomberedzwa, sarudza SCK103S modhi

⑤ SCK105S modhi inosarudzirwa kugadzirisa mapaipi emafuta emichina yepetroleum.

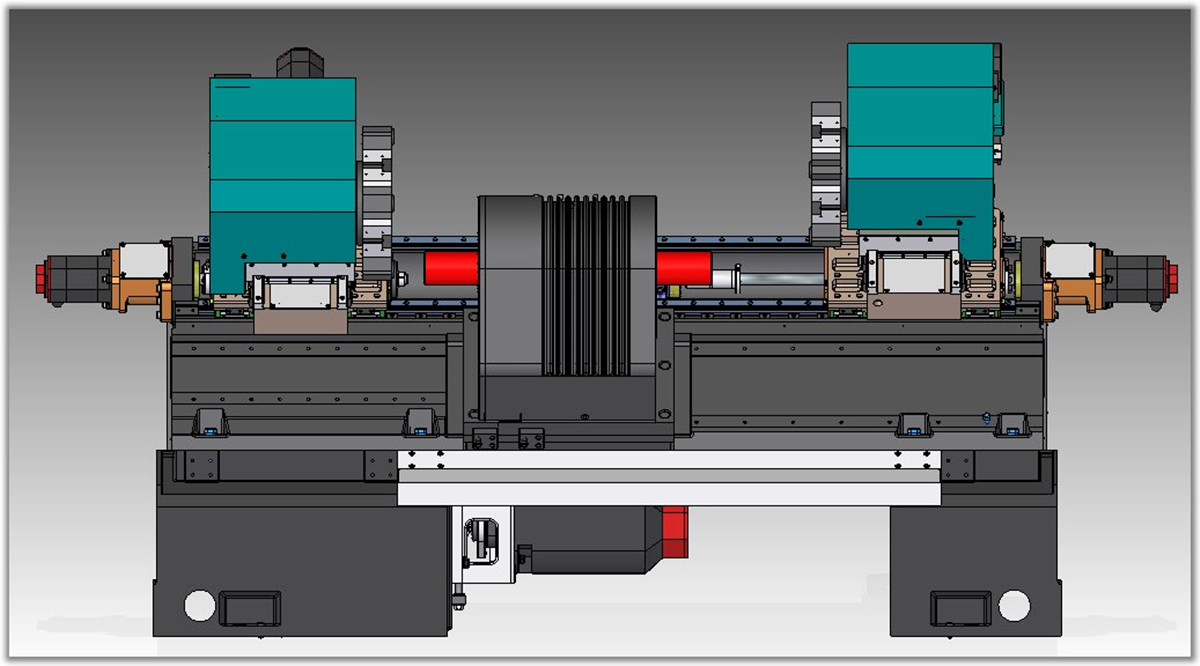

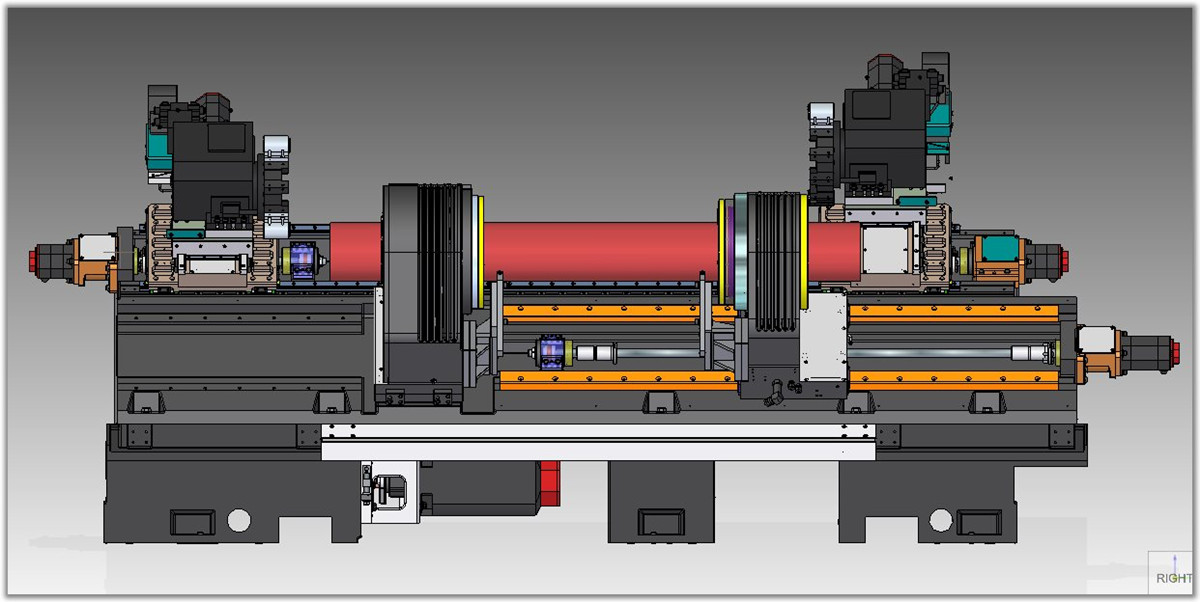

SCK Series Kaviri-kuguma CNC Lathe Sumo

■ Huviri-magumo yepamusoro nyanzvi yeCNC lathe imhando yemhando yepamusoro-soro uye yakakwirira-chaiyo yepamusoro yekugadzira michina. Inogona panguva imwe chete kupedzisa denderedzwa rekunze, kuguma kwechiso uye gomba remukati remigumo miviri yeworkpiece mune imwe clamping. Kuenzaniswa nemaitiro echinyakare ekusungirira zvikamu kaviri uye kutendeuka, ine zvakanakira zvemhando yepamusoro yekugadzira, yakanaka coaxiality uye yakanyanya kurongeka yezvikamu zvakagadziriswa.

Parizvino, kune marudzi anopfuura gumi emhando, clamping dhayamita: φ5-φ250mm, kureba kwekugadzirisa: 140-3000mm; kana yakanyatso kutariswa kune chubhu shell zvikamu, iyo clamping dhayamita inogona kusvika φ400 mm.

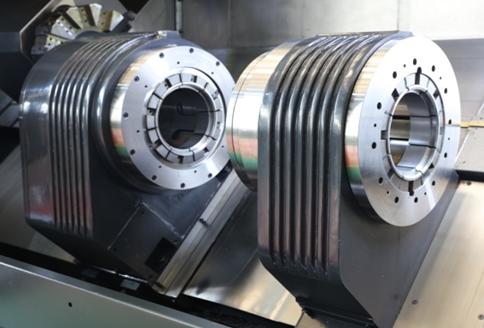

■ Muchina wese une 450 yakarerekera mubhedha marongero, ane yakanaka kuomarara uye nyore kubvisa chip. Iyo spindle bhokisi ine yepakati dhiraivha uye clamping basa rakarongwa pakati pemubhedha, uye maviri maturusi ekuzorora akarongwa pamativi ese eiyo spindle bhokisi.

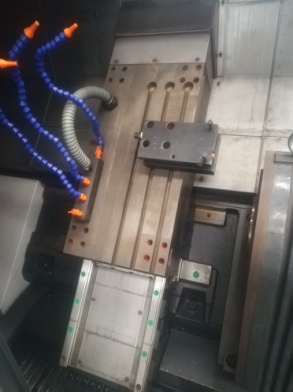

■ Uchishandisa maviri-channel control system, maviri maturusi anozorora anogona kubatanidzwa nechinorunga panguva imwe chete kana kuti zvakasiyana kuti apedze panguva imwe chete kugadzirisa kana kutevedzana kwekupedzisira kwechikamu.

■ Imwe neimwe servo feed axis inotora yakakwira-yakanyarara bhora screw, uye elastic coupling yakabatana zvakananga, ine ruzha rushoma, yakakwirira chinzvimbo chechokwadi uye yakakwirira kudzokorora chinzvimbo.

■ Zvinoenderana nehurefu hwekugadzirisa kweakasiyana workpieces, 1-2 yepakati dhiraivha misoro inogona kuve yakashongedzerwa. Pakati pazvo, bhokisi rekuruboshwe rekuruboshwe rakagadziriswa, uye rekurudyi sub spindle bhokisi rinofambiswa ne servo mota kufambisa bhora screw munzira yeZ. Inogona chete kushandisa iyo huru headstock kusungirira kupedzisa kugadzirisa kwezvikamu zvipfupi; inogona zvakare kushandisa misoro miviri kusungirira pamwe chete kuti ipedze kugadziridzwa kwezvikamu zvakareba.

■ Bhokisi remupinyi rinobatanidza zvikamu zvishanu zvespindle system, clamps, clamping cylinder, oiri yekugovera sisitimu uye mudziyo wekutyaira, ine compact chimiro uye yakavimbika kushanda. Iwo ma clamping zvishandiso zvese zvinofambiswa ne hydraulically, uye iyo clamping simba inogona kusangana nezvinodiwa zveiyo yakanyanya kutendeuka torque.

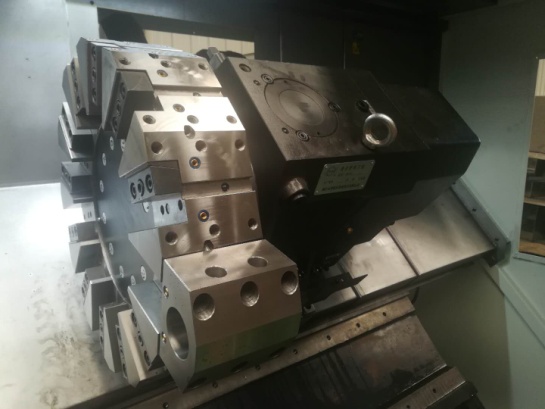

■ Zvigadziriso zvinoiswa mubhokisi rekuruka. Chimiro chezvigadziriso chinosanganisira rudzi rwecollet ine simbi yepakati uye maviri magumo clamp, uye yepakati clamp uye maviri magumo evhavha shaya.

Tichifunga nezve yakareruka deformation maitiro ekubambisa akatetepa-akavakirwa cylindrical zvikamu, collet clamps inowanzo shandiswa. Iwo machira anofambiswa ne cylinder piston kuti aite kuti adederake kuti aone chuck ichisunungura kana kusungirira. Iyo deformation ye elastic chuck ndeye 2-3mm (diameter). Iyo chuck inosungirira iyo inosungirira chikamu chechikamu mune yese circumferential direction, iyo clamping simba yunifomu, uye deformation yechikamu idiki. Kana iko kurongeka kwepamusoro kwechikamu chekurovera kwacho kwakanaka, pachave nekukwirira kwe clamping. Panguva imwecheteyo, zvakakosha kuderedza deformation yezvikamu kuita kuti zvikamu zvive nepamusoro pepamusoro.

■ Kana zvikamu zvine dhayamita yakakura yakatarwa, iyo claw yekugadzirisa inogona kuiswa mune chuck chimiro. Iyo claw inogadzirisa i claw yakapfava, iyo inogadzika padhayamita yemukati yembambo. Usati washandisa, ine yakakwira clamping kurongeka uye nekukurumidza uye nyore kutsiva.

■ Muchina unotora modular dhizaini, uye unogona kuve neakasiyana ezvimiro, zvigadziriso uye anoshanda musanganiswa zvichienderana nezvinodiwa nemushandisi. Kune akawanda sarudzo dzechishandiso positi, senge mutsara chishandiso mhando, turret mhando uye simba turret. Iwo maviri maturusi ekuzorora anogona kubatanidzwa kune spindle panguva imwe chete kana zvakasiyana kuti apedze panguva imwe chete kana sequential kugadzirisa kwemativi ese echikamu.

Mubatanidzwa wemudziyo wemudziyo: kaviri mudziyo unobata; kaviri mutsara mudziyo; simba rekushandisa mubati; mutsara wekuruboshwe+ chibatiso chekurudyi; chibatiso chekuruboshwe + chekurudyi mutsara chishandiso.

■ Chishandiso chemuchina chakavharirwa uye chakachengetedzwa, chine otomatiki lubrication uye otomatiki chip yekubvisa midziyo, ine yakanaka kuchengetedza kuita, kutaridzika kwakanaka, kushanda kuri nyore uye kugadzirisa kuri nyore.

■ Chishandiso chemuchina chinogona kuve chine furemu inotsigira, chishandiso chekubatsira kurodha nekuburitsa, uye chigadziriso chekurodha nekuburutsa. Ona vhidhiyo uye mifananidzo yemuchina.