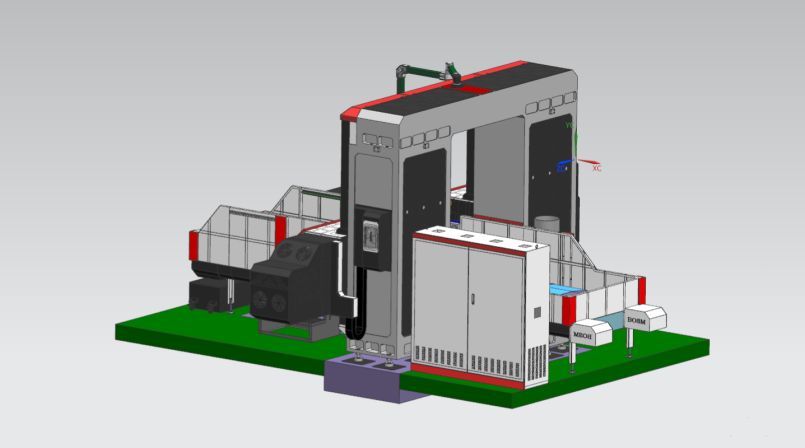

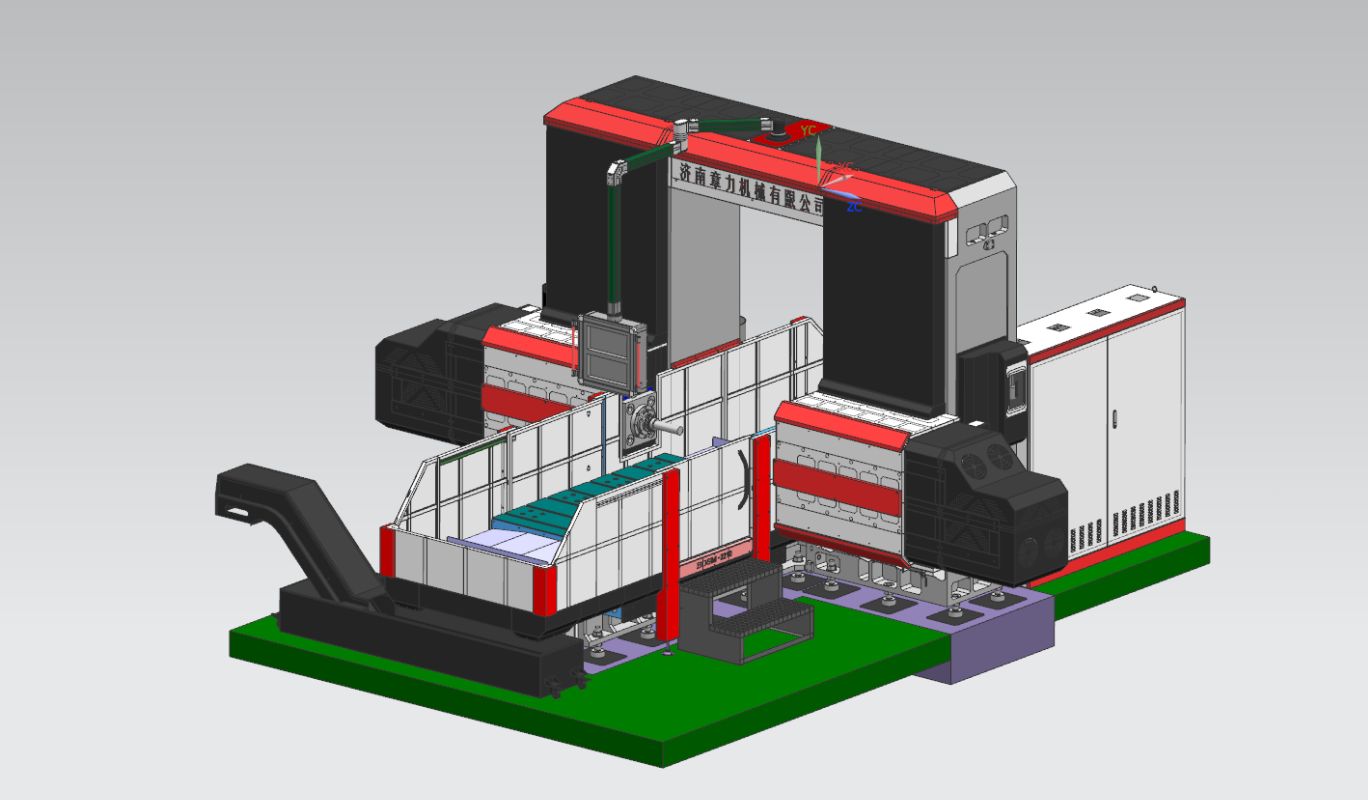

BOSM -5020-5Z Inopikisa-Musoro Boring Milling Machine

1. Kushandiswa kwemidziyo:

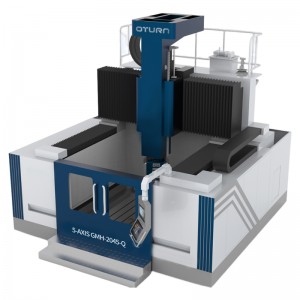

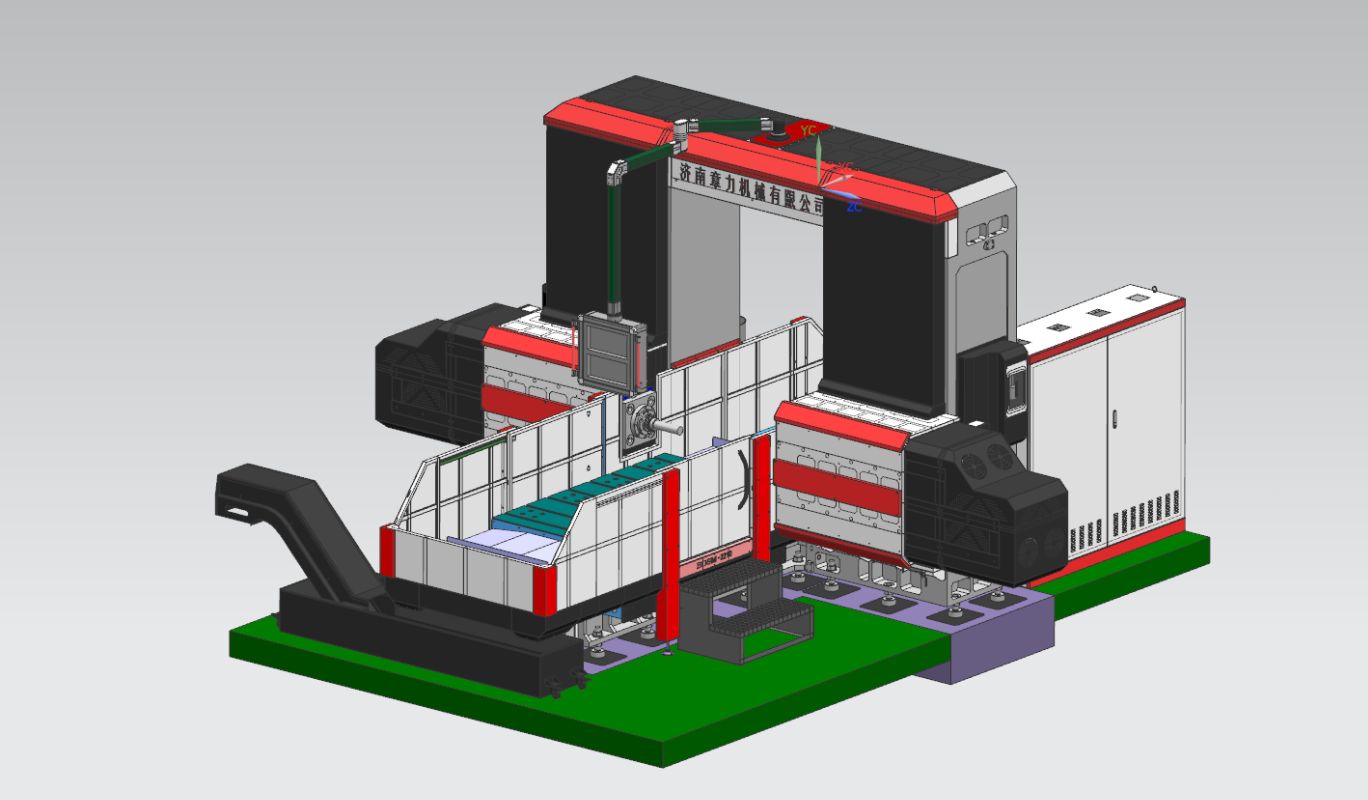

BOSM-5020-5Z CNC workbench mobile double-column head-to-head inofinha uye muchina wekugaya ndiwo wakakosha Muchina weinjiniya michina symmetrical workpieces. Muchina uyu wakashongedzerwa neakakosha anofambiswa bhenji uye maviri seti emakondohwe akachinjika, anogona kuona Kuchera, kugaya, kufinha uye kumwe kugadzirisa kwechishandiso mukati meiyo inoshanda sitiroko renji, iyo workpiece inogona kugadziriswa panzvimbo panguva imwe (hapana chikonzero yechipiri clamping), kukurumidza kurodha uye kurodha kumhanya, kukurumidza chinzvimbo kukurumidza, yakakwirira kugadzirisa kunyatsoita uye yakakwirira kugadzirisa kushanda zvakanaka.

2. Equipment chimiro:

2.1. Zvikamu zvikuru zveMuchina

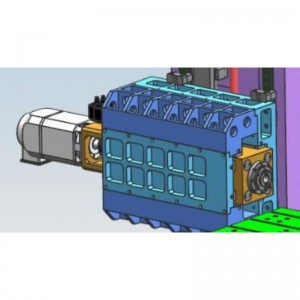

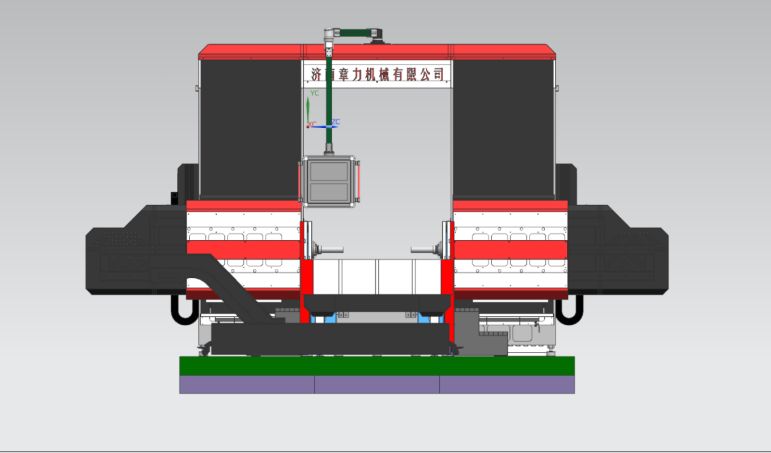

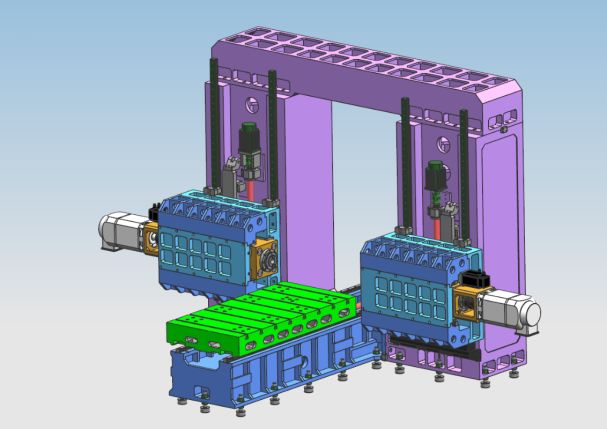

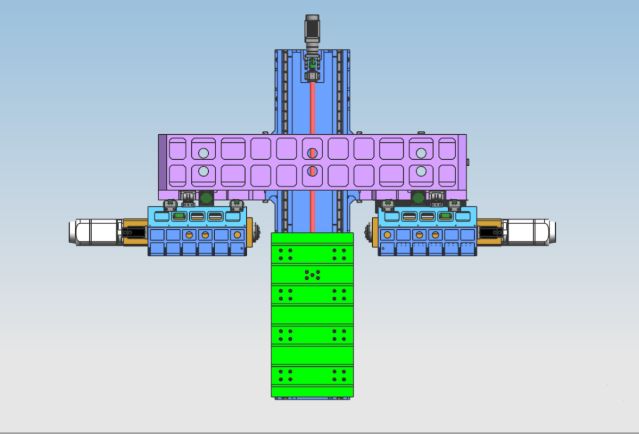

Mubhedha, bhenji rekushanda, mbiru dzekuruboshwe nekurudyi, matanda, matanda ekubatanidza matanda, zvigaro, makondohwe, nezvimwewo, zvese zvakagadzirwa nejecha resin kuumbwa, yemhando yepamusoro grey iron 250 kukanda, yakanyudzwa mugomba rinopisa rejecha → vibration kuchembera → kunyura kwechoto → vibration Kuchembera → kugadzirwa kwakashata → kuzunguzika kuchembera → kunyunguduka kwechoto → kudedera kuchembera → kupedzisa, kubvisa zvachose kusagadzikana kwakashata kwezvikamu, uye chengetedza kuita kwezvikamu zvakadzikama. Iyo yakagadziriswa mubhedha, kuruboshwe uye kurudyi makoramu, gantry, uye bhenji rekushanda; Muchina une chigayo, chinofinha Kucheka, kudhirowa, kunyura, kubaya uye mamwe mabasa, iyo nzira yekutonhodza ndeyekunze kutonhora, Muchina une 5-axis yekubatanidza, 5-axis single-action, 2 simba misoro. , iyo Machine axial uye Musoro wesimba unoratidzwa mumufananidzo uri pazasi.

2.2. Chimiro chikuru cheaxial transmission feed chikamu

2.2.1. X-axis: Iyo tafura yekushanda inodzokororwa nechemberi pamwe negwara renjanji yemubhedha wakamisikidzwa.

X-axis kutapurirana: AC servo mota uye yakakwirira-chaiyo puraneti inoderedza inoshandiswa kutyaira iyo yekushanda kuburikidza nebhora screw transmission kuona X-axis mutsara kufamba.

Gwaro renjanji fomu: isa mbiri-yakasimba-yakasimba mitsara inotungamira njanji

2.2.2.Y1 axis: Musoro wesimba negondohwe zvakamiswa padivi pembiru, uye zvinodzorera kuruboshwe nekurudyi zvichitevedza gwara regwara rembiru.

Y1-axis kutapurirana: AC servo mota inoshandiswa kutyaira bhora screw kutyaira chigaro kuti ifambe, uye kuziva iyo Y1-axis mutsara kufamba.

Gwaro renjanji fomu: 4 zvidimbu zve45 mhando mutsara njanji njanji.

2.2.3.Y2 axis: Gondohwe rechipiri remusoro wesimba rinogadzikwa rakatwasuka kudivi remberi kwembiru, uye rinodzorera kuruboshwe nekurudyi richitevedza gwara regwara rembiru.

Y2-axis kutapurirana: AC servo mota inoshandiswa kutyaira bhora screw kutyaira chigaro chesadhi kuti uone mutsara wekufamba kweY1-axis.

Gwaro renjanji fomu: 4 zvidimbu zve45 mhando mutsara njanji njanji

2.2.4. Z1 axis: Musoro wesimba unotsvedza chigaro chakaiswa padivi padivi pekona yekurudyi, uye inodzokororwa kumusoro nekudzika pamwe negwara renjanji.

Z1-axis kutapurirana: AC servo mota uye yakakwirira-chaiyo puraneti inoderedza inoshandiswa kutyaira gondohwe kuti rifambe nepakati pebhora screw kuti ione Z1-axis mutsara kufamba.

Gwaro renjanji fomu: 2 65 mhando mutsara njanji njanji

2.2.5.Z2 akisi: Chigaro chesimba chine musoro chinotsvedza chinoiswa zvakadzika kudivi remberi kwekoramu yekurudyi, uye chinodzokororwa kumusoro nekudzika zvichitevedza njanji yegwara.

Z1-axis kutapurirana: AC servo mota pamwe nepamusoro-chaiyo puraneti inoderedza inoshandiswa kutyaira gondohwe kuti rifambe nepakati pebhora sikuru kuti uone Z2-axis linear motion.

Gwaro renjanji fomu: 2 65 mhando mutsara njanji njanji

Yemhando yepamusoro HT250 yekukanda mbiru 2 zvidimbu zve65 mhando inorema-basa mutsara njanji

Musoro wesimba unofinha uye wekugaya (kusanganisira musoro wesimba 1 uye 2) igondohwe rakaenzana, uye nzira inofamba inotungamirwa ne4 linear roller guide rails. Iyo drive inoshandisa AC servo mota kutyaira iyo chaiyo bhora screw pair. Muchina uyu une nitrogen balance bar. , Deredza simba rekutakura remusoro wemuchina pane screw uye servo mota. Iyo Z-axis mota ine otomatiki brake basa. Muchiitiko chekutadza kwemagetsi, iyo otomatiki brake inobata shaft yemota zvakasimba kuti isatenderere. Paunenge uchishanda, kana iyo drill bit isingabate workpiece, ichadya nekukurumidza; kana chibooreso chikabata workpiece, chinozochinja otomatiki kuenda kunoshanda feed. Kana iyo drill bit inopinda mukati meiyo workpiece, inozochinja otomatiki kutsanya rewind; kana iyo yekupedzisira yedhiri inosiya iyo workpiece uye inosvika panzvimbo yakatarwa, inoenda kune inotevera gomba chinzvimbo kuti uone otomatiki kutenderera. Uye inogona kuona mabasa ekuboora gomba remapofu, kugaya, chamfering, chip breaking, otomatiki chip kubviswa, nezvimwewo, izvo zvinovandudza basa revashandi.

Iyo 500mm sitiroko yeskweya gondohwe simba musoro inoshandisa mitsetse dhairekitori pachinzvimbo chechinyakare kuisa kunatsiridza zvakanyanya kutungamira uku uchichengeta kuomarara kweskweya gondohwe.

2.3. Kubvisa chip uye kutonhora

Kune spiral uye flat chain chip conveyors akaiswa pamativi ese pasi pebhenji rebasa, uye machipisi anogona kuendeswa otomatiki kune chip conveyor kumagumo kuburikidza nematanho maviri ekutenderera uye cheni mahwendefa kuti uone kugadzirwa kwakabudirira. Pane pombi inotonhodza mutangi inotonhorera yechip conveyor, iyo inogona kushandiswa kutonhora kwekunze kwechishandiso kuve nechokwadi chekushanda uye hupenyu hwesevhisi yechishandiso, uye chinotonhodza chinogona kushandiswazve.

3. Yakazara yedhijitari nhamba yekudzora system:

3.1. Ne chip breaking function, chip breaking time uye chip breaking cycle inogona kuiswa pane man-machine interface.

3.2. Yakashongedzerwa nechishandiso chekusimudza chishandiso, chishandiso chekusimudza chinhambwe chinogona kusetwa pane murume-muchina interface. Kana chinhambwe chasvika, chishandiso chinosimudzwa nekukasira, ipapo machipisi anokandwa kure, uye obva akurumidza kuendeswa kunzvimbo yekuchera uye otomatiki anoshandurwa kushanda.

3.3. Centralised operation control box uye hand-hold unit inotora nhamba yekudzora system uye ine USB interface uye LCD liquid crystal display. Kuti ufambise hurongwa, kuchengetedza, kuratidza uye kutaurirana, iyo interface yekushandisa ine mabasa akadai semurume-muchina dialogue, muripo wekukanganisa, uye otomatiki alarm.

3.4. Iyo midziyo ine basa rekutarisa uye kuongorora zvakare nzvimbo yegomba isati yagadziriswa, uye kushanda kwacho kuri nyore.

4. Automatic lubrication

Machine precision linear guide njanji pairi, precision bhora screw pairs uye mamwe akanyanya-chaiyo mafambiro pairi ane otomatiki lubrication masisitimu. Iyo otomatiki yekuzora pombi inoburitsa kumanikidza mafuta, uye iyo yehuwandu yekuzora mafuta kamuri inopinda muoiri. Mushure mokunge kamuri yemafuta yakazadzwa nemafuta, apo hurongwa hwekumanikidza hunokwira kusvika ku 1.4-1.75Mpa, shanduko yemagetsi muhurongwa yakavharwa, pombi inomira, uye kuvhara kwevhavha inosunungura panguva imwe chete. Kana kudzvinyirirwa kwemafuta mumugwagwa kunodonha pazasi 0.2Mpa, iyo yekuwedzera lubricator inotanga kuzadza nzvimbo yekuzora uye inopedzisa kuzadza mafuta. Nekuda kweiyo chaiyo yekupihwa kwemafuta eiyo yakawanda mafuta injector uye nekuonekwa kweiyo system kudzvanywa, mafuta anopihwa anovimbika, kuve nechokwadi chekuti pane firimu remafuta pamusoro pega yega kinematic pair, kuderedza kukweshera nekupfeka, uye kudzivirira kukuvadzwa. chimiro chemukati chinokonzerwa nekupisa. , kuve nechokwadi chechokwadi uye hupenyu hweMuchina. Kuenzaniswa neinotsvedza njanji njanji, iyo inotenderedza mutsara njanji peya inoshandiswa muMuchina uyu ine nhevedzano yezvakanakira:

①Iyo yekufamba senitivity yakakwira, friction coefficient ye rolling guide njanji idiki, chete 0.0025 ~ 0.01, uye simba rekutyaira rakadzikiswa zvakanyanya, iro rinongofanana ne1/10 yemuchina wakajairwa.

② Musiyano uripo pakati pesimba uye static friction idiki kwazvo, uye yekutevera kuita kwakanakisa, ndiko kuti, nguva yekufamba pakati pechiratidzo chekutyaira uye chiitiko chemuchina ipfupi zvakanyanya, izvo zvinobatsira mukuvandudza kukurumidza kwekupindura uye kunzwa kwe iyo nhamba yekudzora hurongwa.

③Iyo inokodzera kukwirisa-kumhanya kwemutsara, uye kumhanya kwayo kwepakarepo kunokwira kanokwana kagumi pane iya yekutsvedza njanji.

④ Inogona kuona kufamba kusina gap uye kugadzirisa kuoma kwekufamba kweiyo mechanika system.

⑤Inogadzirwa nevagadziri vane hunyanzvi, ine chaiyo chaiyo, yakanaka kuita zvakasiyana-siyana uye nyore kugadzirisa.

5.Matatu-axis laser kuongorora:

Muchina wega wega weBosman wakagadziriswa ne laser interferometer yeRENISHAW kambani kuUnited Kingdom kuti iongorore nemazvo uye kudzoreredza kukanganisa kwepitch, backlash, kurongeka kwenzvimbo, kudzokorora kurongeka kwenzvimbo, nezvimwe, kuve nechokwadi chesimba, kugadzikana uye kugadzirisa iko kurongeka kweiyo muchina . Kuongorora kweBallbar Muchina wega wega unoshandisa bhora kubva kuBritish RENISHAW kambani kuenzanisa chokwadi chedenderedzwa nemazvo emuchina geometric nemazvo, uye kuita ongororo yekucheka denderedzwa panguva imwe chete kuti ive nechokwadi cheiyo 3D machining chokwadi uye denderedzwa chaiyo yemuchina.

6. Mamiriro ekushandisa muchina:

6.1. Equipment kushandisa nharaunda zvinodiwa

Kuchengeta mwero wenguva dzose we ambient tembiricha chinhu chakakosha pakunyatso machining.

(1) Inowanika ambient tembiricha zvinodiwa -10°C kusvika 35°C, kana ambient tembiricha iri 20°C, mwando unofanira kuva 40% kusvika 75%.

(2) Kuti uchengetedze kurongeka kwakamira kweMuchina mukati mechikamu chakatarwa, tembiricha yakakwana inodiwa kuti ive 15 ° C kusvika 25 ° C, uye mutsauko wekushisa haufanire kudarika ± 2 ° C / 24h.

6.2. Simba rekupa magetsi: 3 nhanho, 380V, mukati mehuwandu hwe ± 10% voltage fluctuation, simba rekupa frequency: 50HZ.

6.3. Kana magetsi ari munzvimbo yekushandiswa asina kugadzikana, Muchina unofanirwa kuve wakashongedzwa nemagetsi akagadzikana kuti uve nechokwadi chekushanda kweMuchina.

6.4. Muchina unofanirwa kuve wakavimbika pasi: waya yekugadzika waya yemhangura, waya yacho haifanire kunge iri pasi pe10mm², uye kuramba kwepasi kunofanirwa kunge kuri pasi pe4 ohms.

6.5. Kuti uve nechokwadi chekushanda kwakajairika kwemidziyo, kana iyo yakamanikidzwa mhepo yemhepo sosi isingakwanisi kuzadzisa zvinodiwa nemhepo sosi, seti yemhepo sosi yekuchenesa mudziyo (dehumidification, degreasing, kusefa) inofanira kuwedzerwa isati yapinda mhepo. zveMuchina.

6.6. Chengetedza michina iri kure nechiedza chezuva chakananga, vibration uye zvitubu zvekupisa, majenareta emagetsi emagetsi emagetsi, nezvimwe, kuitira kudzivirira kutadza kwekugadzira Muchina kana kurasikirwa kweMachina.

7.Technical parameters:

| Model | 5020-5Z | |

| Maximum processing workpiece saizi | Kureba × upamhi × kureba (mm) | 5000×2000×2500 |

| Gantry maximum feed | Upamhi (mm) | 2300 |

| kushanda dhesiki saizi | Kureba X Kufara (mm) | 5000*2000 |

| Tafura yekufamba | Workbench inofamba ichidzokera kumashure (mm) | 5000 |

| Gondohwe kaviri simudza kumusoro nekudzika | Kukwira nekudzika kwegondohwe (mm) | 2500 |

| Horizontal gondohwe rudzi kuchera musoro simba musoro mumwe maviri | Huwandu (2) | 2 |

| Horizontal gondohwe rudzi kuchera musoro simba musoro mumwe maviri | Spindle taper | BT50 |

| Spindle kumhanya (r/min) | 30-5000 | |

| Servo spindle mota simba (kw) | 37*2 | |

| Chinhambwe chiri pakati pepakati pemhino inoperera twuviri (mm) | 1500-2500mm | |

| Kuruboshwe nekurudyi kwegondohwe rimwe chete (mm) | 500 | |

| Kuruboshwe nekurudyi kurova kwegondohwe kaviri (mm) | 1000 | |

| Bidirectional Positioning Accuracy | 300mm*300mm | ±0.025 |

| Bi-directional dzokorora kumira zvakanaka | 300mm*300mm | ±0.02 |

| Huremu huremu (t) | (inenge) 55 | Huremu huremu (t) |