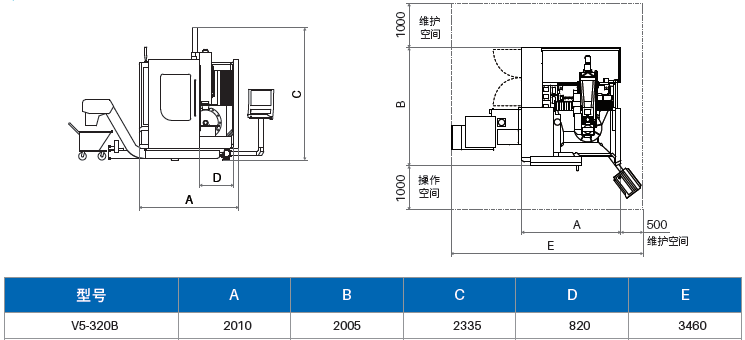

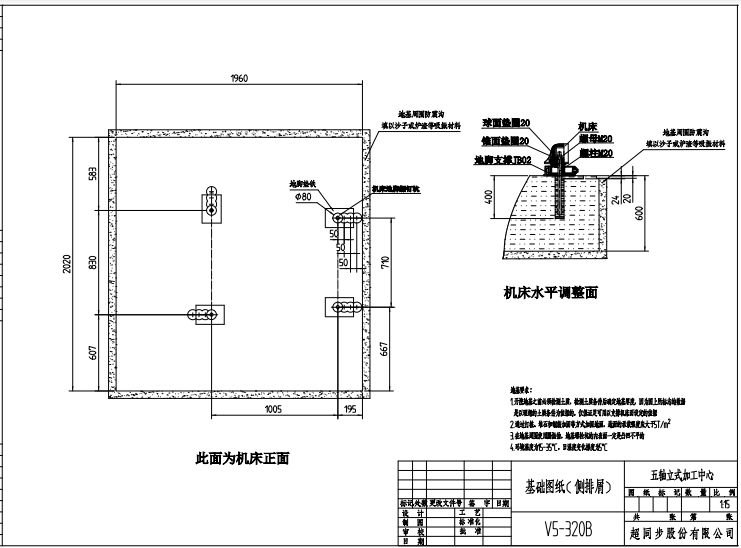

5-Axis Vertical Machining Center V5-320B

1. Yakazara marongero emuchina chishandiso

Iyo V5-320B shanu-axis machining centre inotora yakagadzikana yakaita C-yakaita chimiro, koramu inomisikidzwa pamubhedha, siraidhi ndiro inofamba yakatwasuka pakoramu (X kutungamira), chigaro chinotsvedza chinofamba chakareba padivi redhiraidhi (Y nzira. ), uye musoro wemusoro unofamba wakatwasuka uchitevedza chigaro chesiraidhi (Z kutungamira). Tafura yekushanda inotora iyo yakazvigadzira yakananga-inotyaira imwe-ruoko kiredhi chimiro, uye yayo akasiyana maratidziro ekuita asvika padanho repamusoro renyika.

2. Feed system

X, Y, Z-axis mutsara wegwara njanji uye bhora screws, diki ine simba uye static kukweshera, kunzwisiswa kwakanyanya, kudiki-kumhanya kwekudedera, hapana chinokambaira chakaderera, chakakwira chinzvimbo, uye yakanakisa servo drive kuita.

X, Y, Z-axis servo motors dzakabatana zvakananga nepamusoro-chaiyo bhora screws nekubatanidza, kuderedza epakati zvinongedzo, kuona kutapurirana pasina gap, kuchinjika kudyisa, kwakaringana chinzvimbo, uye yakakwirira kutapurirana chaiko.

Iyo Z-axis servo mota ine brake basa. Muchiitiko chekutadza kwemagetsi, bhureki rinogona kubata shaft yemota zvakasimba kuitira kuti isatenderere, iyo inoita basa rekuchengetedza kuchengetedza.

3. Electric spindle

Iyo yemagetsi spindle inotora yakazvimisikidza yakakwirira-inoshanda electric spindle (yekugadzira patent: 202010130049.4), uye iyo yekupedzisira inoshongedzerwa neinotonhodza nozzles yekutonhodza chishandiso. Iyo ine zvakanakira zvekumhanya zvakanyanya, kunyatsojeka, uye yakakwirira simba mhinduro, uye inogona kuona isina nhanho yekumhanya mutemo. Yakavakirwa-mukati Yepamusoro-chaiyo encoder inogona kuona yakananga kumira uye kuomarara kubata.

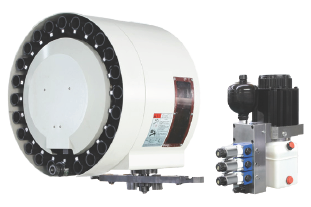

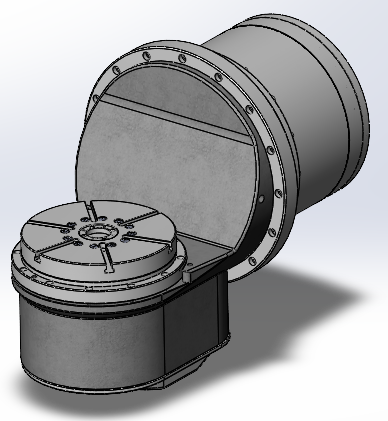

4. Magazini yemidziyo

BT40 disc type tool magazine, 24 tool positions, otomatiki maturusi shanduko neATC manipulator.

Ona pazasi:

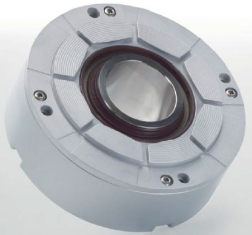

5. Turntable

Iyo inotora iyo yakazvigadzira yakananga-drive single-arm cradle chimiro, iyo ine zvakanakira kusimba kwepamusoro, kurongeka kwepamusoro uye yakakwirira simba remhinduro.

| Axis | Yakatemerwa Torque Nm | Rated Speed rpm | Max. Speed rpm | Yakarongwa Zvazvino A | Rated Power kW |

| B | 656 | 80 | 100 | 18 | 5.5 |

| C | 172 | 100 | 130 | 6.1 | 1.8 |

6. Yakanyatsovharwa loop mhinduro system

X, Y, uye Z mutsara matemo akashongedzerwa neHEIDENHAIN LC4 akatevedzana ukoshi hwakakwana hwekugezera zviyero; Matafura eB neC anotenderedzwa ane HEIDENHAIN RCN2000 akatevedzana kukosha kwemakona encoder kuti azive akazara-akavharwa-loop mhinduro yemademo mashanu ekudyisa, kuve nechokwadi chekuti chishandiso chemuchina chine hunyanzvi hwepamusoro uye nemazvo epamusoro. kunyatsochengetedza.

7. Kutonhora uye pneumatic system

Yakashongedzerwa neinotonhorera yemvura yekutonhodza tembiricha nguva dzose kuti ive nechokwadi chekuti electric spindle uye direct drive turntable zviri mukushanda zvakanaka uye zvinogona kumhanya nemazvo kwenguva yakareba.

Iyo pneumatic system inosefa nepneumatic zvikamu kuti ione mabasa ekuchenesa uye kuvhuvhuta tepi gomba rehombe shaft, mhepo yekuisa chisimbiso kuchengetedzwa kweiyo huru shaft inotakura, uye kupindurudza kwechishandiso magazini uye mudziyo unobata.

8. Centralized lubrication system

Slide block yenjanji yegwara uye nati yebhora screw inotora mudziyo wepakati wekuzora negirizi yakatetepa, iyo inopa yakajairika uye yakawanda lubrication kuti ive nechokwadi chekurongeka uye kugadzikana kwebhora screw uye gwara renjanji.

9. Workpiece yekuyera system

Chishandiso chemuchina chine HEIDENHAIN TS460 yekubata probe uye isina waya inogashira siginecha, iyo inogona kuisirwa pane spindle kuburikidza nemanyorero kana otomatiki chishandiso shanduko system kuona mabasa ekurongeka kweworkpiece, kuyerwa kweworkpiece uye preset point yekumisikidza, uye kuyerwa kudzokororwa kuri ≤ 1um (yekuongorora kumhanya 1 m/min), tembiricha yekushanda i10°C kusvika 40°C. Iyo HEIDENHAIN yekubata probe inokonzereswa neiyo optical switch. Iyo stylus inoshandisa matatu-mapoinzi bearing kuti ive yakanakira yemahara state chinzvimbo. Iyo isingapfeki-isina panguva yekushandiswa, ine inongo dzokorora uye yakagadzikana kwenguva yakareba.

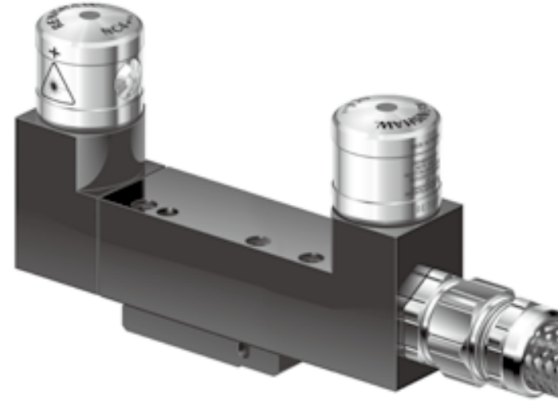

10. Chishandiso chekuyera hurongwa

Chishandiso chemuchina chine Renishaw NC4 laser chishandiso chekuisa chiridzwa, kuyerwa kudzokororwa kuri ± 0.1um, uye tembiricha yekushanda i5 ° C kusvika 50 ° C.

11. Mashanu-axis precision calibration

Chishandiso chemuchina chakashongedzerwa neKKH calibration mabhora kubva kuHEIDENHAIN, pamwe chete neTS akateedzera probes, kuwana chaiyo calibration yemuchina wemuchina wekutenderera axis, kuderedza zvikanganiso panguva yekufamba kwechishandiso chemuchina, uye kuwana chaiyo chaiyo uye yakakwirira kudzokorora.

12. Kudzivirirwa kwechigadzirwa chemuchina

Chishandiso chemuchina chinotora chivharo chekudzivirira chinosangana nemaitiro ekuchengetedza kudzivirira kutonhora uye machipisi kubva pakupfapfaidza, kuve nechokwadi chekushanda kwakachengeteka, uye kuve nechitarisiko chinofadza. Iyo X dhizaini yechishandiso chemuchina yakashongedzerwa nenhoo yezvombo, iyo inogona kunyatso chengetedza gwara renjanji uye bhora screw.

13. Machine tool kushanda mamiriro

(1) Simba rekushandisa: 380V±10% 50HZ±1HZ matatu-chikamu AC

(2) Tembiricha yepakati: 5°C-40°C

(3) Kunyanya tembiricha: 22°C-24°C

(4) Hunyoro hunyoro: 20-75%

(5) Mhepo sosi yekumanikidza: ≥6 bar

(6) Gasi sosi inoyerera mwero: 500 L / min

14. Basa rekutanga reCNC system

HEIDENHAIN TNC640 CNC system

(1) Nhamba yematemo: kusvika ku24 control loops

(2) Bata screen vhezheni ine akawanda-touch mashandiro

(3) Chirongwa chekuisa: Klartext kutaurirana uye G kodhi (ISO) chirongwa

(4) FK yemahara contour programming: shandisa Klartext yekukurukurirana programming mutauro kuita FK yemahara contour programming ine graphic rutsigiro.

(5) Kugaya nekuchera kwakawanda

(6) Tool compensation: tool radius muripo uye mudziyo kureba muripo. Probe cycle

(7) Kucheka data: otomatiki kuverenga kwespindle kumhanya, kucheka kumhanya, chikafu pablade uye chikafu padenderedzwa

(8) Constant contour processing speed: inoenderana negwara renzvimbo yekushandisa / hama kumucheto kwechishandiso

(9) Parallel Run: Chirongwa chine rutsigiro rwemifananidzo apo chimwe chirongwa chiri kushanda

(10) Contour zvinhu: mutsara wakatwasuka/chamfer/arc nzira/pakati denderedzwa/denderedzwa radius/tangentially yakabatana arc/yakatenderedzwa kona

(11) Kusvika uye kubva kune contours: tangential kana perpendicular / kuburikidza nearc nzira

(12) Chirongwa kusvetuka: subroutine / chirongwa block kudzokorora / chero chirongwa chinogona kunge chiri subroutine

(13) Canned cycle: kuchera, kubaya (ine kana isina inoyangarara tapping furemu), rectangular uye arc cavity. Peck drilling, reming, boring, spot yakatarisana, kuchera nzvimbo. Kugaya shinda dzemukati nekunze. Kukoromoka kwenzvimbo dzakati sandara uye dzakarerekera. Yakazara machining ehomwe rectangular uye denderedzwa, rectangular uye denderedzwa maboss. Roughing uye kupedzisa kutenderera kune yakatwasuka uye denderedzwa grooves. Rongedza zvibodzwa pamadenderedzwa nemitsetse. Array point: QR kodhi. Contour cheni, Contour homwe. Contour groove ye trochoidal milling. Engraving denderedzwa: nyora zvinyorwa kana nhamba pamwe nemutsara wakatwasuka kana arc.

(14) Rongedza shanduko: kushandura, kutenderera, girazi, kuyera (chaiyo axis).

(15) Q parameter variable programming: basa remasvomhu, mashandiro ane musoro, mashandiro evabereki, kukosha kwakakwana, nguva dzose þ, kuregeredza, nhamba kana decimal, basa rekuverenga denderedzwa, basa rekugadzirisa zvinyorwa.

(16) Zvirongwa zvinobatsira: karukureta. Rondedzero yemeseji dzese dzezvino kukanganisa. Context-sensitive kubatsira basa remhosho dzemeseji. TNCguide: yakabatanidzwa rubatsiro system; iyo TNC 640 inoratidza ruzivo zvakananga kubva mubhuku remushandisi. Graphical rutsigiro rwekutenderera programming. Comment mabhuroki uye mabhuroko makuru muzvirongwa zveNC.

(17) Kuwana ruzivo: shandisa zvakananga chinzvimbo muNC chirongwa.

(18) Chirongwa chekuongorora magiraidhi: Graphical simulation yemachining mashandiro anogona kuitwa kunyangwe imwe chirongwa chiri kushanda. Yepamusoro maonero / matatu-dimensional maonero / stereo maonero, uye yakarerekera kugadzirisa ndege / 3-D mutsara dhizaini. Local scaling.

(19) Programming graphics support: Kunyange kana imwe purogiramu iri kushanda, magirafu (2-D handwriting tracing diagram) of the input NC programme segment inogona kuratidzwa mu program editing operation mode.

(20) Chirongwa chinomhanya magiraidhi: chaiyo-nguva giraidhi simulation paunenge uchiita chirongwa chekugaya. maonero epamusoro / matatu maonero / stereo maonero.

(21) Kugadzirisa nguva: Verenga nguva yekugadzirisa mu "test run" inoshanda mode. Inoratidza yazvino machining nguva mu "Program Run" inoshanda mode.

(22) Dzokera kune contour: ratidza ikozvino yekugadzirisa nguva mu "chirongwa chiri kushanda" maitiro ekushanda. Kuvhiringidzwa kwepurogiramu, kusiya uye kudzokera kune contour.

(23) Preset point management: tafura yekuchengetedza chero preset point.

(24) Mabviro tafura: akawanda emavambo matafura, anoshandiswa kuchengetedza hukama hweiyo workpiece.

(25) 3-D Machining: Motion Control yeHigh Quality Smooth Jerk

(26) Block processing time: 0.5 ms

(27) Kugadziriswa kwekuisa uye danho rekuratidzira: 0.1 μm

(28) Kuyera kutenderera: probe calibration. Manual kana otomatiki muripo we workpiece misalignment. Seta preset mapoinzi nemaoko kana otomatiki. Chishandiso uye workpiece inogona kuyerwa otomatiki.

(29) Mhosho muripo: mutsara uye usiri mutsara axis kukanganisa, backlash, reverse inopinza kona yekufamba kwedenderedzwa, reverse kukanganisa, kuwedzera kupisa. static friction, sliding friction.

(30) Data interface: RS-232-C/V.24, kusvika 115 kbit/s. Yakawedzerwa data interface yeLSV2 protocol, shandisa HEIDENHAIN TNCremo kana TNCremoPlus software yekushandisa uri kure TNC kuburikidza neiyi data interface. 2 x Gigabit Ethernet 1000BASE-T interface. 5 x USB ports (1 kumberi USB 2.0 port, 4 USB 3.0 ports).

(31) Kuongororwa: Zvishandiso zvega zvega zvekuongorora zvekukurumidza uye zviri nyore kugadzirisa matambudziko.

(32) CAD muverengi: ratidza akajairwa CAD fomati mafaera.

Main parameter

| Item | Unit | Parameter | |

| Worktable | worktable dhayamita | mm | 320 |

| Maximum horizontal load | kg | 150 | |

| Maximum vertical load | kg | 100 | |

| T-slot | mm | 8X10H8 | |

| Processing range | Distance pakati pespindle end face uye worktable end face (Max) | mm | 430 |

| Distance pakati pespindle end face uye worktable end face (Min) | mm | 100 | |

| X axis | mm | 450 | |

| Y axis | mm | 320 | |

| Z axis | mm | 330 | |

| B axis | ° | -35°~+ 110° | |

| C axis | ° | 360° | |

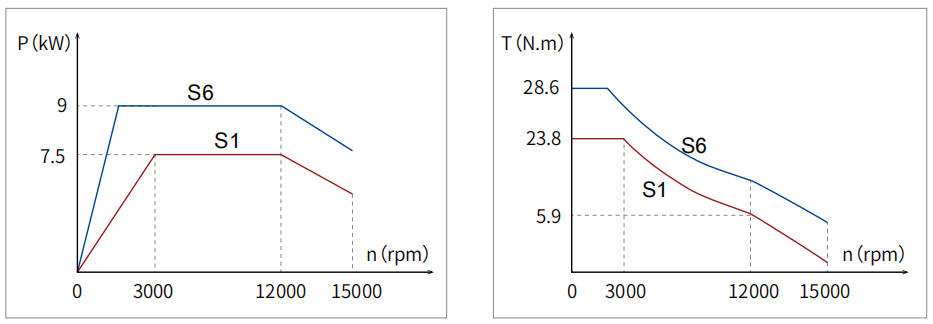

| Spindle | Taper(7 ∶ 24) |

| BT40 |

| Rated speed | rpm | 3000 | |

| Max. speed | rpm | 15000 | |

| Yakatemerwa torque S1 | Nm | 23.8 | |

| Yakatemerwa Simba S1 | KW | 7.5 | |

|

Axis | X axis Inokurumidza kuyambuka kumhanya | m/min | 36 |

| Y axis Rapid transverse speed | m/min | 36 | |

| Z axis Inokurumidza kuyambuka kumhanya | m/min | 36 | |

| B axis Max. speed | rpm | 130 | |

| C axis Max. speed | rpm | 130 | |

| Tool magazine | Type |

| Disc type |

| Nzira yekusarudza Tool |

| Bidirectional yepedyo yekushandisa sarudzo | |

| Capacity | T | 24 | |

| Max. mudziyo kureba | mm | 150 | |

| Max. mudziyo uremu | kg | 7 | |

| Max. cutter disc dhayamita (Chishandiso Chizere) | mm | 80 | |

| Maximum cutter disc dhayamita (Yakatarisana isina chinhu chishandiso) | mm | 150 | |

| Kururama | Executive mwero |

| GB/T20957.4(ISO10791-4) |

| X-axis/Y-axis/Z-axis positioning kururama | mm | 0.008/0.008/0.008 | |

| B-axis/C-axis positioning kururama |

| 7"/7" | |

| X-axis/Y-axis/Z-axis inodzokorora kurongeka chaiko | mm | 0.006/0.006/0.006 | |

| B-axis/C-axis inodzokorora kurongeka chaiko |

| 5"/5" | |

| Machine uremu | Kg | 5000 | |

| Kukwana kwemagetsi | KVA | 45 | |

Standard Configuration List

| Aihwa. | Zita |

| 1 | Zvikamu zvikuru (kusanganisira mubhedha, koramu, siraidhi ndiro, siraidhi chigaro, headstock) |

| 2 | X, Y, Z matatu-axis feed system |

| 3 | Single arm cradle turntable |

| 4 | Yemagetsi spindle BT40 |

| 5 | Electrical control system (inosanganisira magetsi emagetsi, magetsi emagetsi module, servo module, PLC, operation panel, kuratidza, handheld unit, yemagetsi kabati air conditioner, nezvimwewo) |

| 6 | Grating scale: HEIDENHAIN |

| 7 | Hydraulic system |

| 8 | Pneumatic system |

| 9 | Centralized lubrication system |

| 10 | Chip conveyor, tangi remvura, chip muunganidzi |

| 11 | Rail guard |

| 12 | Muchina chishandiso chese chivharo chekudzivirira |

| 13 | Chishandiso chekuyeresa chishandiso: HEIDENHAIN TS460 |

|

| Linear zviyero HEIDENHAIN |

| 14 | Chishandiso chekumisikidza chiridzwa: HEIDENHAIN NC4 |

| 15 | Shanu-axis precision calibration: HEIDENHAIN KKH |

| 16 | Kubva pane imwe pfungwa yekushandisa yeHPMILL post-processing software, sunga kero yekombuta |

| 17 | Spindle thermal elongation compensation function |