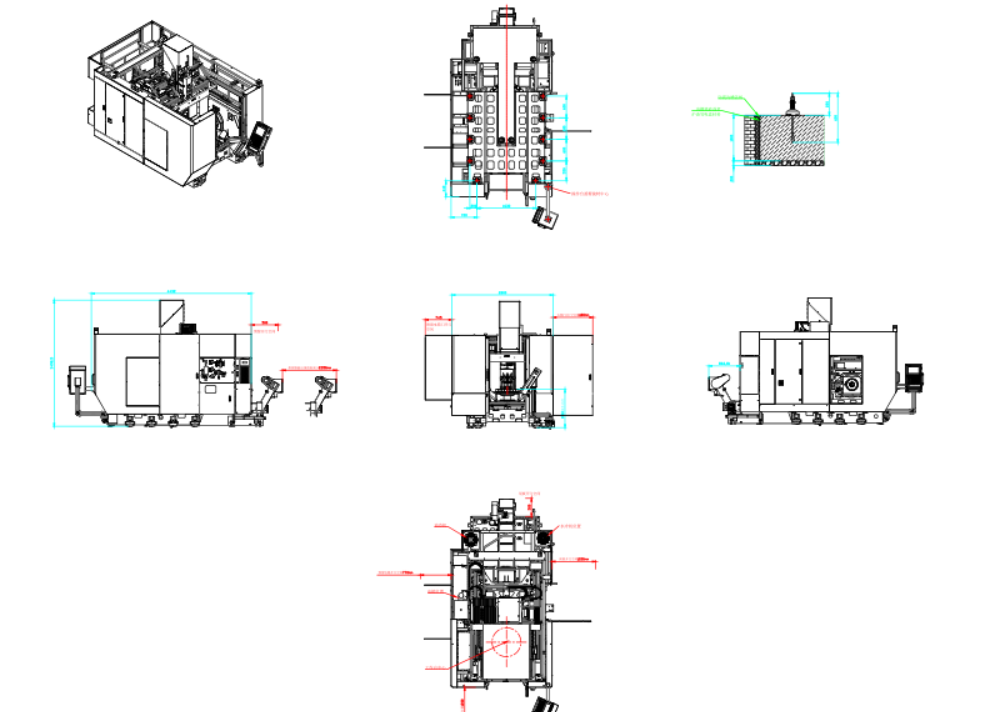

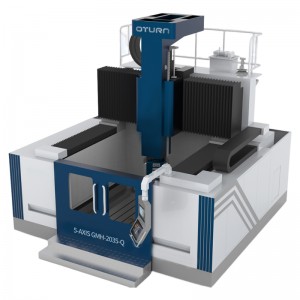

High-speed nemazvo zambuko mhando machining centre CBS650

1.Machine Overview

Iyo CBS650 inomhanya kwazvo, kuita kwepamusoro, yakakwira chaiyo bhiriji mhando 5-axis machining centre ine kusimba kwepamusoro, kurongeka kwepamusoro uye kunyatsoshanda. Muchina wese wakagadzirwa neinogumira element ongororo kuti ipe yakanyanya kunaka kugadzikana kuita.

Matemo matatu anokurumidza kusimuka 48 M/min, TT chishandiso chekuchinja nguva chete 4S, chishandiso magazini yakazara mutoro 24 maawa chishandiso shanduko isina alarm yekumhanyisa muchina uye imwe neimwe yemuchina wekuyedza sampuli ye3 nguva kuburikidza neye element test, kuve nechokwadi chekuti muchina unoshanda uye kugadzikana kunoenderera mushure mekusiya fekitori. Inokodzera marudzi ese emhando dzakaomarara dzemaviri uye matatu dimensional concave uye convex modhi inoda 5-axis yekubatanidza yekutanga kugadzirisa, uyezve, yakakodzera kune ese madiki uye epakati batch emhando dzakasiyana-siyana kugadzirisa kugadzirwa, uye zvakare inogona kupinda. iyo otomatiki mutsetse wekugadzirwa kwehuwandu.

Iyo yazvino TNC640 sisitimu kubva kuHEIDENHAIN, ine 15-inch hombe LCD kuratidza, yakangwara yambiro kuratidza uye kuzviongorora wega, inoita kuti muchina uwedzere nyore kushandisa nekuchengetedza; iyo yakawanda-segment pre-read control inonyanya kukodzera kune yakakwirira-kumhanya uye yakakura-inogoneka chirongwa chekugadzirisa, uye inotsigira network uye USB chirongwa chekufambisa, iyo inofambisa kukurumidza uye inobudirira kutapurirana kweakakura-kugona zvirongwa uye online processing.

2.Main parameter

| Item | Unit | tsanangudzo | |

| Trevel | X/Y/Z axis kufamba | mm | 800×900×560 |

| Distance from spindle end to table surface | mm | 110-670 | |

| Maximum chinhambwe kubva kuspindle centre kusvika patafura pa90° yeA-axis | mm | 560 | |

| Maximum machining range | mm | φ800*560 | |

| C-axis turntable

| Diameter ye disc surface | mm | Φ650 |

| Turntable T-slot/guide kiyi hupamhi | mm | 14H7/25H7 | |

| Inobvumirwa mutoro | kg | 350 | |

| Matatu-axis feed | X/Y/Z-axis kukurumidza kutama | m/min | 48/48/48 |

| Kucheka kukurumidza kwekudya | mm/min | 0-12000 | |

| spindle | Spindle zvirevo (kukwira dhayamita / nzira yekufambisa) | mm | 170/mukati yakavanzwa |

| Spindle taper yakaboora | mm | A63 | |

| Maximum spindle speed | r/min | 18000 | |

| Spindle mota simba (inoenderera/S3 15%) | kW | 22/26 | |

| Spindle mota torque (inoenderera / S3 15%) | Nm | 56.8/70 | |

| Tool magazini | Tool magazini kukwanisa |

| 30T |

| Tool exchange time (TT) | s | 4 | |

| Max. mudziyo dhayamita | mm | 80/120 | |

| Max. mudziyo kureba | Mm | 300 | |

| Max. mudziyo uremu | kg | 8 | |

| Guide Rail | X-axis gwara (saizi/nhamba yemasiraidhi) | mm | 452 |

| Y-axis gwara (saizi/nhamba yemasiraidhi) | 45/2 | ||

| Z-axis gwara (saizi/nhamba yemasiraidhi) | 35/2 | ||

|

Matemo matatu | X mutsara mota thrust (inoenderera / yakakura) | N | 3866/10438 |

| Y linear mota thrust (inoenderera / yakakura) | N | 3866/10438 | |

| Z-axis screw | N | 2R40*20 (shinda kaviri) | |

|

Axis mashanu | C-axis yakayerwa/yepamusoro kumhanya | rpm | 50/90 |

| C axis yakayerwa / yakakura yekucheka torque | Nm | 964/1690 | |

| A-axis positioning/kudzokorora kunyatsoita | arc-sec | 10/6 | |

| C-axis positioning/kudzokorora kunyatsoita | arc-sec | 8/4 | |

| Nhatu axis kururama

| Positioning kururama | mm | 0.005/300 |

| Dzokorora kurongeka kwechokwadi | mm | 0.003/300 | |

| Lubrication System

| Lubrication unit capacity | L | 0.7 |

| Rubrication type |

| Kuzora mafuta | |

| Kucheka mvura | Tangi yemvura inokwana | L | 300 |

| Kucheka pombi parameters |

| 0.32Mpa×16L/min | |

| vamwe | Kudiwa kwemhepo | kg/c㎡ | ≥6 |

| Mwero wekuyerera kwemhepo | mm3/min | ≥0.5 | |

| Simba rekupa simba | KVA | 45 | |

| Uremu hwemuchina (akasanganiswa) | t | 17 | |

| Dimension (L×W×H) | mm | 2760×5470×3500 | |

3.Standard configuration

| 序号 | Zita |

| 1 | Siemens 840D system |

| 2 | Panguva imwe chete kubaya basa |

| 3 | X/Y/Z/A/C yakavharwa zvizere loop system |

| 4 | X/Y/C axis yakananga dhiraivha mota control |

| 5 | X/Y/C axial tembiricha yekudzora system |

| 6 | Spindle tembiricha yekudzora system |

| 7 | Spindle overload protection |

| 8 | Yakavharwa zvizere pepa simbi |

| 9 | Chengetedzo gonhi rekuvhara system |

| 10 | Otomatiki gonhi rematurusi magazini |

| 11 | Automatic girisi lubrication system |

| 12 | LED basa mwenje mwenje |

| 13 | Mechanical chishandiso kuseta uye chishandiso kuseta mudziyo (Medron) |

| 14 | Kusimudza chip conveyor system |

| 15 | Machining kuvhuvhuta system |

| 16 | Peripheral spraying system |

| 17 | Inotonhorera system |

| 18 | Standard turusi uye bhokisi rekushandisa |