Heavy Duty CNC Drilling Milling Machine

CNC Drilling uye Milling Machine

High-speed CNC yekuchera uye milling muchina

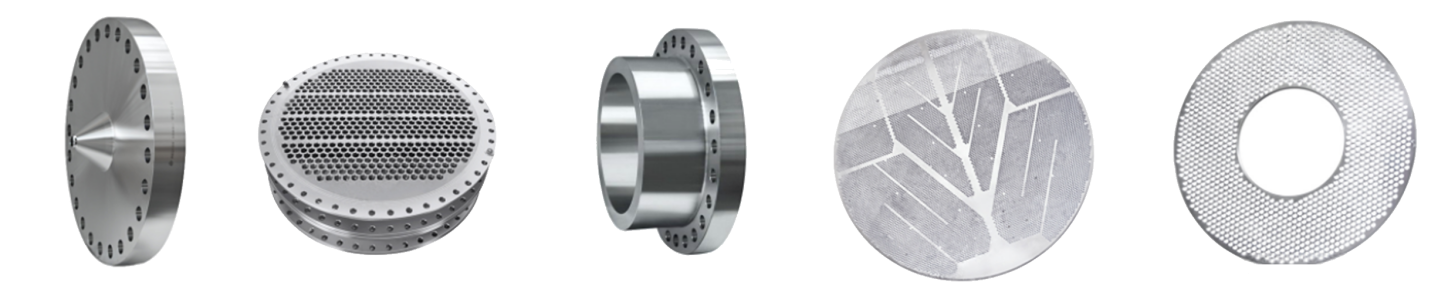

Machine Application

CNC yekuchera uye milling michina inonyanya kushandiswa kudhiraivha kwakanaka kwemaworkpiece ane ukobvu mukati meiyo inoshanda renji senge mahwendefa, flanges, disks uye zvindori. Kuburikidza nemaburi nemabofu anogona kuboorwa pamhando dzakasiyana dzezvinhu. Muchina uyu unodzorwa nedhijitari nekushanda kuri nyore. Inogona kuwana otomatiki, yakanyanya kurongeka, akawanda marudzi, kugadzirwa kwemazhinji.

Kuti isangane nezvinodiwa zvekugadzirisa zvevashandisi vakasiyana, kambani yedu yakagadzira akasiyana michina. Kuwedzera kune akajairwa mamodheru, inogona zvakare kugadziridzwa zvinoenderana nezvinodiwa chaizvo zvevatengi.

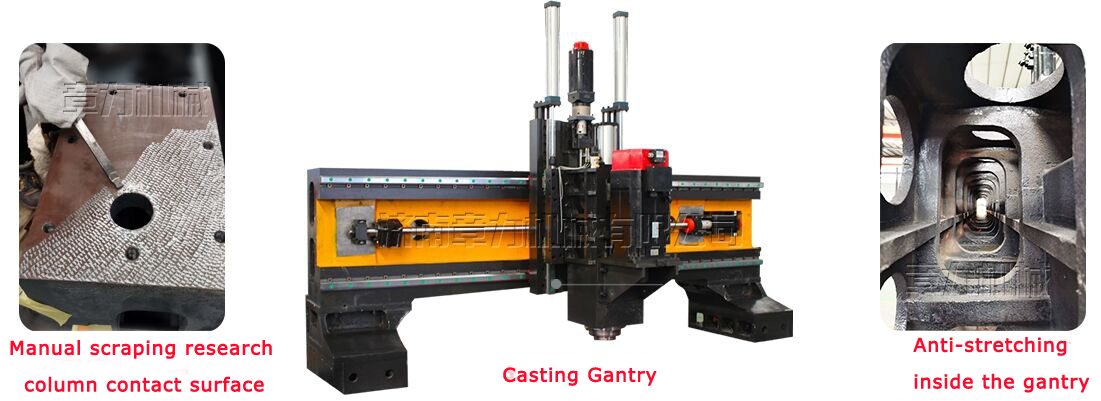

Machine Structure

Midziyo iyi inonyanya kuumbwa netafura yemubhedha, gantry inofamba, inotsvedza chigaro, kuchera uye kugayo spindle, otomatiki lubrication mudziyo uye mudziyo wekudzivirira, inotenderera inotonhorera mudziyo, CNC control system, magetsi system uye zvichingodaro. Iyo inotsigira uye inotungamira yeinotenderedza mutsara gwara uye chaiyo lead screw drive, muchina une yakakwirira chinzvimbo kurongeka uye inodzokororwa yekumisikidza kurongeka.

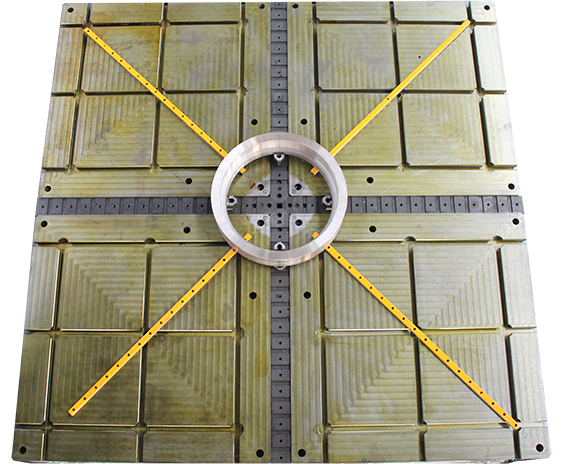

1)Worktable:

Tafura yekushanda inotora chimiro chekukanda, uye ndege ine T-slot ine inonzwisisika yekupedzisa dhizaini ye clamping workpieces. Pamusoro pemubhedha, T-slots yakarongwa. Iyo drive system inoshandisa AC servo mota uye chaiyo bhora screw kutyaira pamativi ese kuita gantry kufamba munzira yeY-axis. Mabhoti anogadziriswa akagoverwa pasi pemubhedha, izvo zvinogona kugadzirisa nyore nyore chiyero chetafura yemubhedha.

2)Movinggantry:

Iyo mobile gantry inokandwa negrey iron 250, uye maviri epamusoro-akakwirira-anogona rolling mutsara gidhi pairi akaiswa kumberi kwegantry. Seti yechaiyo bhora screw pair uye servo mota inoita kuti simba remusoro ritsvedze kufamba munzira yeX-axis. Musoro wesimba rekuchera unoiswa pane simba remusoro slide. Kufamba kwe gantry kunoitwa ne servo mota inotyaira waya yebhora pa bhora screw kuburikidza nechaiyo coupling.

3)MovingSliding saddle:

Iyo mobile sliding saddle ndeye chaiyo yakakanda simbi dhizaini chikamu. Maviri e-ultra-high-capacity NC njanji masiraidhi uye seti yechaiyo bhora screw pairs uye yakakwirira-chaiyo yepuraneti inoderedza inobatanidzwa kune servo mota kutyaira iyo yekuchera simba musoro. Kufamba munzira yeZ-axis kunogona kuona nekukurumidza kumberi, kushanda kumberi, kukurumidza kudzosera kumashure, uye kumira kwemusoro wesimba. Ne otomatiki chip breaking, chip kubviswa, kumbomira mabasa.

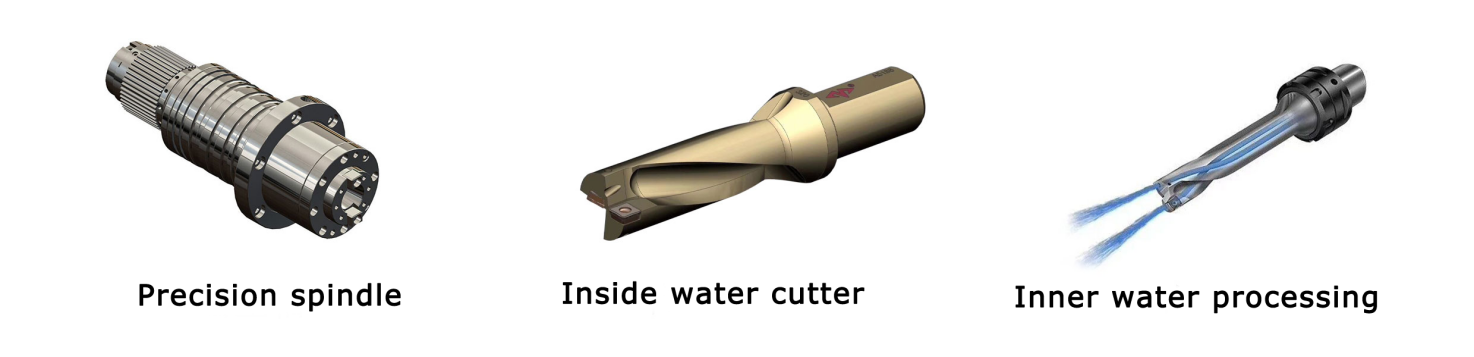

4)Kuchera simba musoro(Spindle):

Musoro wesimba rekuchera unoshandisa yakatsaurirwa servo spindle mota, iyo inotyaira yakazvitsaurira chaiyo spindle nekudzikisa mazino synchronous bhandi kuti iwedzere torque. Iyo spindle inoshandisa kumberi kwechitatu, mbiri, uye shanu-mitsara yeJapan angular yekubata mabhengi kuti uwane nhanho yekumhanya shanduko. Kurumidza uye nyore kutsiva, chikafu chinofambiswa ne servo mota uye bhora screw. Iyo X uye Y axes inogona kubatanidzwa, uye semi-yakavharwa loop control inoshandiswa kuita mutsara uye denderedzwa interpolation mabasa.

Spindle end is BT40 tapered gole, ine Rotorfoss high-speed rotary joint kubva kuItaly, inogona kushandisa high-speed U drill (chisimba chibooresa) uye core drill bit kuburitsa mvura. ziva yakadzika gomba kugadzirisa uye chengetedza chishandiso kudzikisa mutengo wekushandisa.

5)Otomatiki lubrication mudziyo uye kudzivirira mudziyo:

senge njanji, lead screws, racks, nezvimwewo, isina makona akafa kuti ave nechokwadi chehupenyu hwesevhisi yechishandiso chemuchina. Iyo X-axis uye Y-axis yemuchina mudziyo wakashongedzerwa neguruva-uchapupu hwekudzivirira zvivharo, uye isina mvura inoputika magadhi akaiswa akatenderedza workbench.

6)CNC Kudzora System:

6.1Ne chip breaking function, chip breaking time uye chip breaking cycle inogona kuiswa pane man-machine interface.

6.2 Iine chishandiso chekusimudza basa, iyo yekusimudza kukwirira kwemudziyo inogona kuiswa pane murume-muchina interface. Paunenge uchichera kusvika pakureba uku, chibooreso chinokurumidza kusimudzwa kumusoro kwechigadzirwa chebasa, uye ipapo chip chinokandwa, uye chinobva chakurumidza kuendeswa kunzvimbo yekuchera uye chingoshandurwa kushanda.

6.3Iyo centralized operation control box uye hand-hold unit inotora nhamba yekudzora system, uye ine USB interface uye LCD liquid crystal display. Kuti ufambise hurongwa, kuchengetedza, kuratidza uye kutaurirana, iyo interface yekushandisa ine mabasa akadai semurume-muchina dialogue, muripo wekukanganisa, uye otomatiki alarm.

6.4Muchina uyu une basa rekutarisa uye kuongororazve nzvimbo yegomba usati wagadziriswa, uye kushanda kwacho kuri nyore.

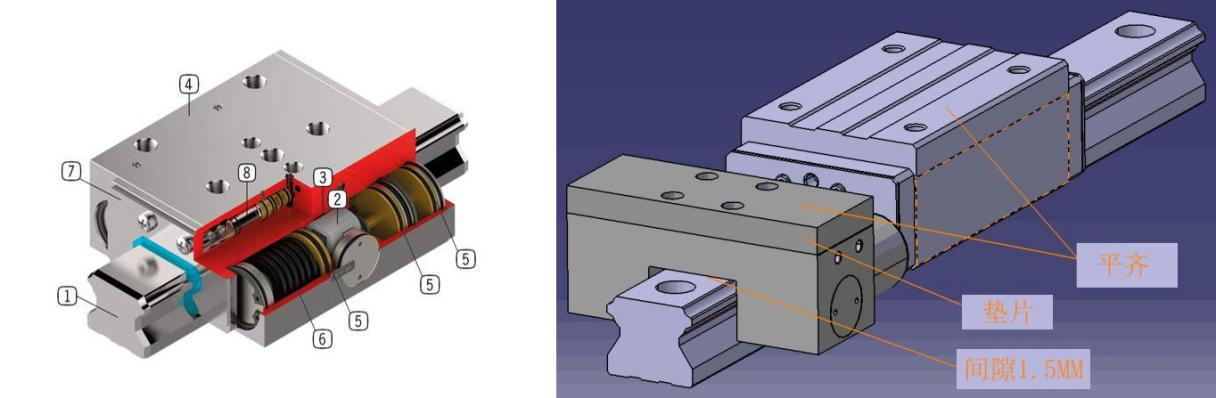

7)Rail clamp

Iyo clamp inoumbwa nemuviri wekusungirira uye actuator. Icho chikamu chepamusoro-chinoshanda chinoshandiswa ne rolling linear guide pair. Iyo inoburitsa yakasimba clamping simba kuburikidza neiyo wedge-yakaita block block yekuwedzera musimboti. Zvimiro zvinowedzera kuoma.

Features:

- Yakachengeteka uye yakavimbika, yakasimba clamping simba, clamping isiri-inofamba XY axis panguva yekudhirowa nekutapa kugadzirisa.

- Yakanyanya kukwirira clamping simba, wedzera kuomarara kweiyo axial feed, uye kudzivirira iyo micro movement inokonzerwa nekudengenyeka.

- Kupindura nekukurumidza, kuvhura uye kuvhara nguva yekupindura ingori 0.06 masekonzi, inodzivirira chishandiso chemuchina uye inovandudza hupenyu hwescuru.

- Yakasimba, nickel-plated pamusoro, yakanaka anti-rust performance.

Novel dhizaini kudzivirira kuomarara kukanganisa kana uchirovera.

8)Otomatiki chip remover uye inotenderera inotonhorera mudziyo:

Iyo otomatiki chip remover inorongedzerwa kuseri kwebhenji rebasa uye sefa inorongwa kumagumo. Iyo otomatiki chip remover imhando yakatsetseka cheni, uye pombi inotonhorera inoiswa kune rimwe divi. Iyo yekubuda kweiyo chip yakabatana kune yepakati mvura kusefa system. Iyo inotonhorera inoyerera ichipinda mu chip ejector. Iyo chip ejector inosimudza pombi inotyaira inotonhorera mukati mepakati pemvura kusefa system. Iyo pombi yekutonhodza yepamusoro-soro inotenderera inotonhorera yakasefa yekucheka nekutonhodza. Uye ine trolley yekutakura chip, iri nyore kutakura machipisi esimbi. Mudziyo uyu wakashongedzerwa nemukati nekunze kutonhora system yevanocheka. Pakuchera nekumhanya kukuru, makucheka anotonhodzwa nemvura yemukati uye kunze panguva yekugaya chiedza.

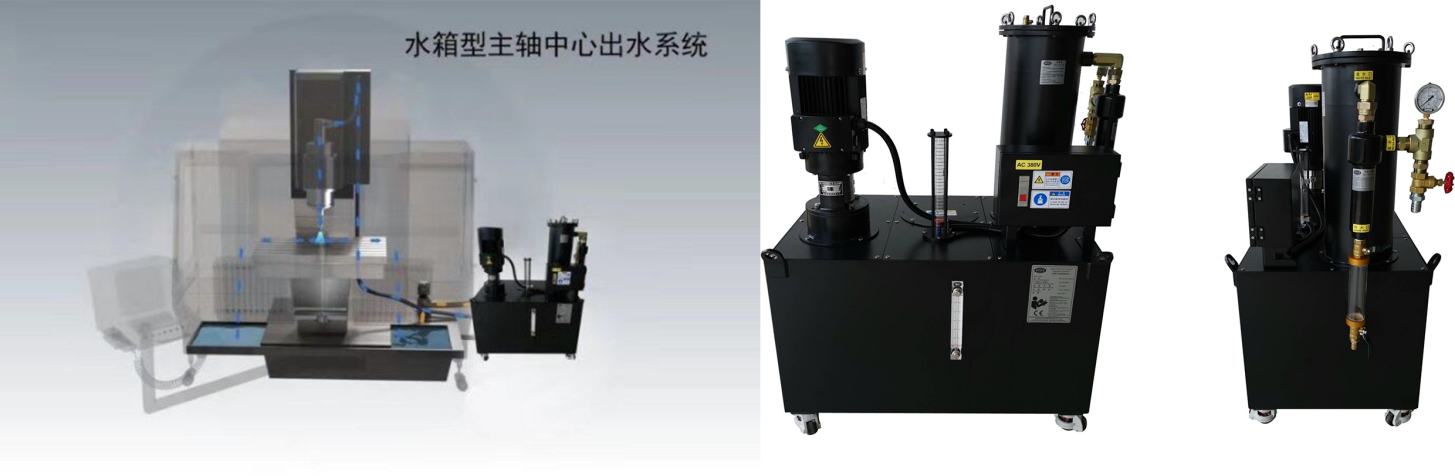

Alamu yemvura yakaderera

1) Kana chinotonhodza chiri musefa chiri pakati pemvura nhanho, sisitimu inongobatanidza mota kuti itange, uye inotonhorera mu chip remover inoyerera ichipinda musefa. Kana iyo yakakwirira yemvura level yasvikwa, mota inomira kushanda.

2) Kana iyo inotonhorera iri musefa iri padanho rakaderera, sisitimu inozosimudzira iyo geji yegeji yemvura kuti iite alarm, iyo spindle inodzoreredza chishandiso, uye muchina unomisa basa.

9)Central Outlet Filtration System:

Muchina uyu wakashongedzerwa nepakati pemvura kusefa system seyakajairwa, iyo inogona kunyatso kusefa tsvina mune inotonhorera. Iyo yemukati yekupfapfaidza mvura sisitimu inogona kudzivirira mapini esimbi kubva pakusungirira pane chishandiso panguva yekugadzira, kuderedza kupfeka kwechishandiso, kuwedzera hupenyu hwechishandiso, kuvandudza workpiece pamusoro pekupedzisira, Iyo yakakwira-inomanikidza mvura yekubuda pini yeblade tip inogona kunyatso chengetedza pamusoro peiyo workpiece, chengetedza yakakwira-speed rotary joint, kudzivirira tsvina kubva pakuvharira rotary joint, uye kunatsiridza huwandu hwese hweworkpiece uye kushanda zvakanaka.

10)Bhora screw uye mota yakabatanidzwa chigaro:

Iyo mota base ndeye yakakwira concentricity chigadzirwa chinobatanidza bhora screw uye mota. Iyo angular yekubata paired kubereka (chaiyo giredhi C5) inosanganiswa kuvandudza iko uye kuve nechokwadi zero axial clearance yebhora screw kana mota iri kumberi nekudzokera kumashure. Inonyanya kukodzera midziyo yepamusoro.

Kurongeka kwegungano: bhora screw uye mota inoiswa mune imwe kuburikidza neiyo mota base. Deredza kukanganisa kukanganisa kwemota shaft uye bhora screw shaft, ridzore pakuwedzera kana kubvisa 0.01mm, uye perpendicularity yekuguma kwechiso ndeye 0.01.

11)Four-claw self-centering table(sarudzo)

Iyo yekushanda yemidziyo yekuzvimiririra ine ina-shaya hydraulic self-centering chuck. Iyo workpiece inogona kuiswa pakati otomatiki mune imwe clamp pasina yega yega workpiece patrolling kuti uwane nzvimbo. Iyo clamping inokurumidza uye yakanakira.

Gadzirisa dambudziko iro chidimbu chebasa chine indexing denderedzwa isingasviki 1600 mm dhayamita inosungirirwa nekutsikirira ndiro mushure mekudya uye wozotsvaga pakati, iyo inopedza nguva shoma uye inotora nguva yakareba yekusunga pane kugadzirisa nguva.

Kuzvimisa-pakati pechina-shayi chuck yakazvimiririra yakazvimiririra ine hombe shaya sitiroko inoita kuti zviome kuti workpiece ibate shaya kana ichisunga. Iyo mitsetse yekugadzira ine pad inoshandiswa.Inogadzirisa mamiriro ezvinhu ekuti hydraulic kana pneumatic shaya dzine zvishoma kufamba pamusika uye mahombe workpieces anozokanganisa shaya kana uchisimudza, zvichikonzera kukuvadza kune chucks.

Mashaya mana ari pabhandi rekushanda ari muchimiro chisingagoneki, uye kubviswa kwebhenji rekumashure inzvimbo yakajairwa ine T-groove yayo.

Specificationn

| Model | BOSM-DT1010 | BOSM-DT2010 | BOSM-DT2016 | BOSM-DT2525 | |

| Saizi yekushanda | Kureba*Kufara (mm) | 1000x1000 | 2000x1000 | 2000x1600 | 2500x2500 |

| Vertical Drilling Head | Spindle taper | BT40/ BT50 | BT40/ BT50 | BT40/ BT50 | BT40/ BT50 |

| Kuchera dhayamita (mm) | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | |

| Kubata dhayamita (mm) | M24 / M36 | M24 / M36 | M24 / M36 | M24 / M36 | |

| Spindle kumhanya (r/min) | 30-3000 | 30-3000 | 30-3000 | 30-3000 | |

| Spindle simba (Kw) | 15/22 | 15/22 | 15/22 | 15/22 | |

| Chinhambwe kubva kumucheto wepasi pechipindo kuenda kunzvimbo yebasa (mm) | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | 200 ~ 600 / 400 ~ 800 | |

| Dzokorora Positioning Kururama (X/Y/Z) | X/Y/Z | ± 0.01/1000mm | ± 0.01/1000mm | ± 0.01/1000mm | ± 0.01/1000mm |

| Huremu huremu (T) | 8.5 | 11 | 13.5 | 16.5 | |

| Chishandiso chemagazini | Line tool magazine | ||||

Quality Inspection

Muchina wega wega weBosman wakarongedzerwa nelaser interferometer kubva kuUnited Kingdom RENISHAW kambani, iyo inoongorora nemazvo uye nekubhadhara zvikanganiso zvepitch, backlash, kurongeka kwenzvimbo, uye inodzokororwa yekumisikidza kurongeka kuti ive nechokwadi chekusimba kwemuchina, kugadzikana, uye kugadzirisa iko kurongeka. . Bhora bhawa bvunzo Muchina wega wega unoshandisa bhora rekuyedza kubva kuBritish RENISHAW kambani kugadzirisa chokwadi denderedzwa nemazvo uye muchina geometric nemazvo, uye kuita ongororo yekucheka denderedzwa panguva imwe chete kuti ive nechokwadi chemuchina we3D machining huchokwadi uye denderedzwa rechokwadi.

Pamberi & Mushure meSevhisi

1) Pamberi peSevhisi

Kuburikidza nekudzidza chikumbiro uye ruzivo rwakakosha kubva kune vatengi uye mhinduro kune mainjiniya edu, Bossman Technical timu ine basa rekukurukurirana kwehunyanzvi nevatengi uye kugadzira mhinduro, kubatsira mutengi mukusarudza yakakodzera machining mhinduro nemichina yakakodzera.

2) Mushure meSevhisi

A. Muchina une waranti yegore rimwe uye wakabhadhara kuchengetedza kwehupenyu hwese.

B.Munguva yewaranti yegore rimwe chete mushure mekunge muchina wasvika pachiteshi chengarava, BOSSMAN ichapa mahara uye panguva yakakodzera masevhisi ekugadzirisa zvikanganiso zvakasiyana-siyana zvisiri-zvakaitwa nemunhu pamushini, uye panguva yakakodzera kutsiva marudzi ese ezvisiri-zvinokuvadza zvikamu zvemahara. of charge . Kutadza kunoitika panguva yewaranti kuchagadziriswa pamutengo wakakodzera.

C.Technical tsigiro mumaawa makumi maviri nemana pamhepo, TM, Skype, E-mail, kugadzirisa hama mibvunzo nenguva. kana isingagadziriswe, BOSSMAN inokurumidza kuronga kuti mushure mekutengesa-injiniya kuti asvike pa-saiti kuti igadziriswe, mutengi anoda kubhadhara VISA, matikiti endege uye pekugara.

Company Site