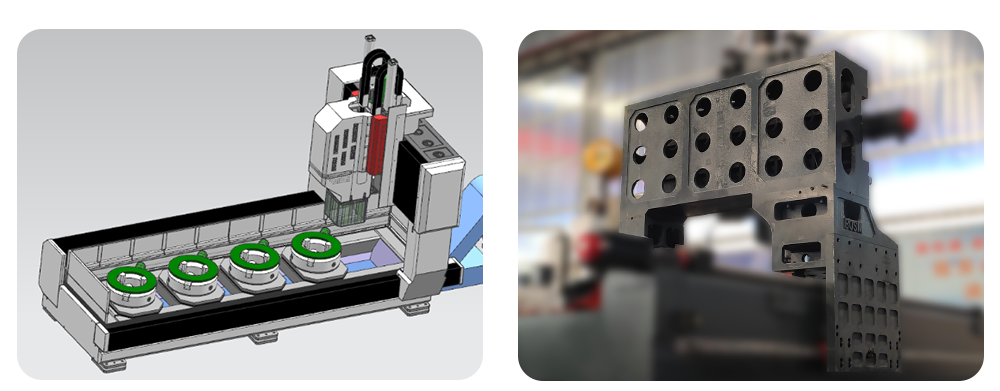

Ina Chiteshi Shaft Flange Drilling Machine

Machine Features

Iyo ina-zviteshi flange CNC yekuchera uye milling muchina nhepfenyuro inonyanya kushandiswa kutenderera flange kugadzirisa, uye inogona zvakare kushandiswa kudhiraivha / kugaya kwemaworkpiece ane ukobvu mukati meiyo inoshanda senge hafu shafts, flat plate, flanges, disks uye zvindori. / Kubata / kugadzirazve / kunyora uye mamwe maitiro. Kuburikidza-maburi uye mapofu maburi anogona kuroverwa pane zviri nyore zvinhu zvemukati uye zvinhu zvakaumbwa. Muchina wekushandisa unodzorwa nedhijitari kuti ushande nyore. Inogona kuwana otomatiki, yakanyanya kurongeka, akawanda marudzi, kugadzirwa kwemazhinji.

Machine Structure

Muchina uyu unonyanya kuve netafura yebasa, mana seti e hydraulic mana-shaya anozvigadzirira chucks, nhare ye gantry, nhare yekutsvedza chigaro, yekuchera nekugaya simba musoro, otomatiki lubrication mudziyo uye mudziyo wekudzivirira, inotenderera inotonhorera mudziyo, a. digital control system, uye yemagetsi system. Etc composition. Iyo inotsigira uye inotungamira yeinotenderedza mutsara gwara uye iyo chaiyo lead screw drive, chishandiso chemuchina chine yakakwirira chinzvimbo chechokwadi uye yakadzokororwa chinzvimbo.

1.Tafura yebasa remubhedha:

Mubhedha wakagadzirwa nesimbi structural parts. Inopedzwa nekurapa kwechipiri kupisa. Iyo ine yakanaka dynamic uye static rigidity uye haina kukanganisa. Iyo tafura yekushanda inoshandisa mana seti e500mm ina-shaya-yega-centering hydraulic chucks yekukurumidza kusungirira kwezvishandiso. Maviri e-ultra-high-capacity linear rolling guide pairs akaiswa kumativi ose emubhedha. Mushure mekumisikidza, iwo maviri seti ekunze akakwira-kusimba kukiya Iyo ine simba njanji yekusungirira yakamira yakasimba uye yakakiyiwa pachinjanji. Iyo clamp inokwana zvakakwana pasina kukuvadza njanji inotsvedza. Iyo clamp yekuvhura uye nguva yekuvhara ingori 0.06 masekonzi, iyo inopfupisa zvakanyanya nguva yekugadzirisa. Iyo drive system inoshandisa bhazi absolute servo mota uye nemazvo Iyo bhora screw inotyaira gantry kuti ifambe munzira yeY-axis. Mabhoti anogadziriswa akagoverwa pasi pemubhedha, izvo zvinogona kugadzirisa nyore nyore chiyero chetafura yemubhedha.

2.Mobile Gantry:

Iyo mobile gantry inokandwa ne grey iron 250. Kureba kwedanda rinorema ndeye 800mm kuti iwedzere simba rayo. Maviri epamusoro-akakwirira-akakwirira-anotenderedza mutsara gidhi pairi akaiswa kumberi kwegantry. Iyo yebhuruu inotsvedza inoshandisa chaiyo bhora screw pair uye servo mota kufambisa iyo simba musoro inotsvedza munzira yeY axis. Musoro wesimba rekuchera unoiswa pane simba remusoro slide. Kufamba kwe gantry kunoitwa ne servo mota inotyaira bhora screw amai kutenderera pabhora screw kuburikidza nechaiyo coupling.

3.Mobile sliding saddle:

Iyo mobile sliding saddle ndeye chaiyo yakakanda simbi dhizaini chikamu. Iyo sadhi yekutsvedza inokwidziridzwa uye inowedzera kuwedzera nzvimbo yepakati peiyo gwara renjanji. Maseti maviri e-ultra-high-capacity rolling linear guide rail pairs uye precision bhora screw pairs akabatana kune yakakwirira-chaiyo ruoko Iyo brake servo mota inotyaira musoro wesimba rekuchera kuti ufambe munzira yeZ-axis, inogona kuona nekukurumidza kumberi, kufambira mberi kwemaindasitiri, kukurumidza kudzosera kumashure, uye kumira kwemusoro wesimba. Ne otomatiki chip breaking, chip kubviswa, kumbomira mabasa.

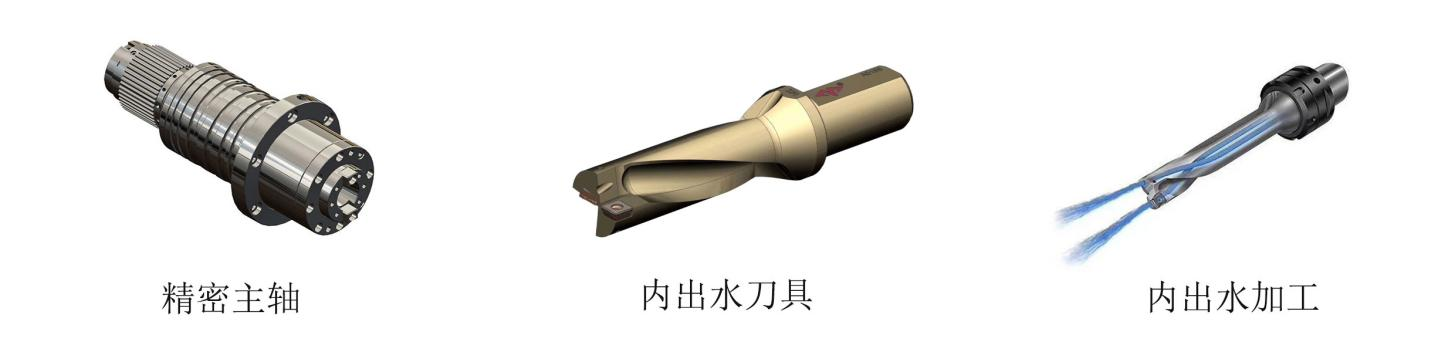

4.Drilling power head:

Musoro wesimba rekuchera unoshandisa yakatsaurirwa servo spindle mota. Iyo chaiyo mechanical spindle inofambiswa nekudzikira kweiyo toothed synchronous bhandi kuti iwedzere torque. Iyo spindle inoshandisa kumberi kwechitatu, mbiri, uye shanu-mitsara yeJapan angular yekubata mabhengi kuti uwane nhanho yekumhanya shanduko. Kurumidza uye nyore kutsiva, chikafu chinofambiswa ne servo mota uye bhora screw. Iyo X uye Y axes inogona kubatanidzwa, uye semi-yakavharwa loop control inogona kushandiswa kuwana mutsara uye denderedzwa kududzira mabasa.

5. Flat cheni otomatiki chip conveyor uye inotenderera inotonhorera mudziyo

Muchina uyu une flat chain otomatiki chip conveyor uye chip muunganidzi. Iyo inotenderera inotonhorera mudziyo yakashongedzerwa nepepa sefa, iyo ine yakakwira-kumanikidza mukati mepombi inotonhorera uye yakaderera-inodzvinyirira kunze kwekutonhora kwepombi yemukati uye kunze kutonhora kwechishandiso.

5.1 Automatic lubrication mudziyo uye inodzivirira mudziyo:

Muchina uyu wakashongedzerwa neyekutanga yeTaiwan volumetric partial pressure otomatiki yekuzora mudziyo, inogona kungozora mafuta njanji, lead screws uye mamwe mapeya anofamba, uye hapana kona yakafa yekuona hupenyu hwesevhisi yemuchina. Iyo X-axis uye Y-axis yemuchina mudziyo wakashongedzerwa neguruva-uchapupu hwekudzivirira zvivharo, uye isina mvura inoputika magadhi akaiswa akatenderedza workbench.

6. CNCcontrol system:

6.1. Ne chip breaking function, chip breaking time uye chip breaking cycle inogona kuiswa pane man-machine interface.

6.2. Iine chishandiso chekusimudza basa, chishandiso chekusimudza kureba chinogona kusetwa pane murume-muchina interface. Paunenge uchichera kusvika paurefu uhwu, chibooreso chinokurumidza kusimudzwa pamusoro pechishandiso, uye ipapo chip chinopwanyika, uye chinobva chakurumidza kuendeswa kunzvimbo yekuchera uye chinoshandurwa otomatiki kubasa.

6.3. Iyo centralized operation control box uye handheld unit inotora nhamba yekudzora system, uye ine USB interface uye LCD kuratidza. Kuti ufambise hurongwa, kuchengetedza, kuratidza uye kutaurirana, iyo interface yekushandisa ine mabasa akadai semurume-muchina dialogue, muripo wekukanganisa, uye otomatiki alarm.

6.4. Midziyo yacho ine basa rekutarisa uye kuongororazve nzvimbo yegomba isati yagadziriswa, uye kushanda kwacho kuri nyore.

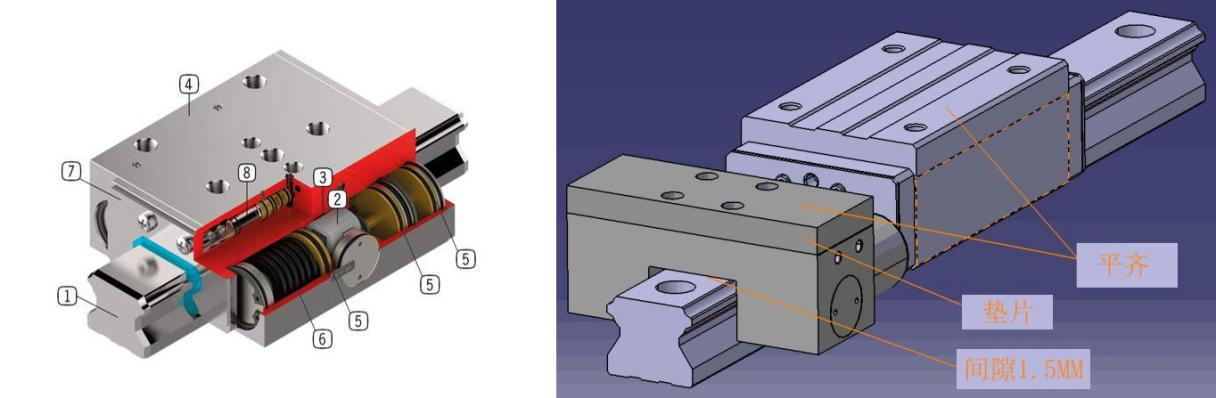

7.Rail clamp:

Iyo clamp inoumbwa nemuviri mukuru weiyo clamp, actuators, etc. Icho chinhu chepamusoro-chekuita chinoshanda chinoshandiswa pamwe chete ne rolling linear guide pair. Kuburikidza nemusimboti wewedge block force yekuwedzera, inoburitsa yakasimba clamping simba; ine gantry yakagadziriswa, nzvimbo chaiyo, anti-vibration uye Basa rekuvandudza kuoma.

Ine zvinotevera maitiro:

Ø 1)Yakachengeteka uye yakavimbika, yakasimba clamping simba, kusungirira iyo isiri-inofamba XY axis panguva yekuchera uye nekutepa kugadzirisa.

Ø 2)Iyo yakanyanya kusimba yekumanikidza inowedzera kuomarara kweiyo axial feed uye inodzivirira kushushikana kunokonzerwa nekudengenyeka.

Ø 3)Kurumidza kupindura, yekuvhura nekuvhara yekupindura nguva ingori 0.06 masekondi, ayo anogona kuchengetedza mudziyo wemuchina uye kuwedzera hupenyu hweiyo lead screw.

Ø 4) Yakasimba, nickel-plated pamusoro, yakanaka anti-ngura kuita.

Ø 5)Novel dhizaini kudzivirira kuomarara kukanganisa kana kuomesa.

Speification

| Model | BOSM-DS500 | Unit | |

| Maximum workpiece saizi | Kunze dhayamita | 50-500 | mm |

| Maximum workpiece urefu | 300 | Kg | |

| Half shaft workpiece dhayamita | ≤200 | mm | |

| Shaft kureba | 700mm inogona kuwedzerwa maererano nenheyo | mm | |

| Workpiece ukobvu | ≤5 nguva dzekuboora dhayamita | mm | |

| Vertical gondohwe mhando yekuchera simba musoro | QTY | 1 | Pcs |

| Spindle taper | BT40 | ||

| Drill dhayamita | Φ2-Φ36 | mm | |

| Tapping range | M6-M24 | ||

| Spindle speed | 30-3000 | r/mm | |

| Servo spindle mota simba | 15 | Kw | |

| Distance kubva spindle kuzasi kuenda worktable | 150-550mm±20 | mm | |

| Lateral kufamba kwemusoro wesimba (X Axis) | MAX. travel | 2600 | mm |

| X Axis kumhanya | 0~8 | m/min | |

| X Axis servo mota simba | 2.4 | Kw | |

| Longitudinal kufamba kwedanda rinofamba (Y Axis) | MAX. travel | 500 | mm |

| Y Axis kumhanya | 0~8 | m/min | |

| Y Axis servo mota simba | 2.4 | Kw | |

| Vertical sleeper feed movement (Z axis) | MAX. travel | 400 | mm |

| Z axis kumhanya | 0~4 | m/min | |

| Z Axis servo mota simba | 1 × 2.4 bhureki | Kw | |

| Positioning kururama | 500x500 | ±0.03 | mm |

| Kunyatsoita indexing | 360° | ±0.001° | |

| Machine size | Kureba x upamhi x kureba | 3600×1650×2300 | mm |

| Machine uremu | 8.5 | T | |

Quality Inspection

Muchina wega wega wakarongedzerwa nelaser interferometer kubva kuUnited Kingdom RENISHAW kambani, iyo inonyatso ongorora uye nekubhadhara zvikanganiso zvepitch, backlash, kurongeka kwenzvimbo, uye inodzokororwa yekumisikidza kurongeka kuti ive nechokwadi chekusimba kwemuchina, kugadzikana, uye kugadzirisa iko kurongeka. . Bhora bar bvunzo Muchina wega wega unoshandisa bhora rekuyedza kubva kuBritish RENISHAW kambani kugadzirisa chokwadi chedenderedzwa uye ma.

chine geometric kurongeka, uye ita denderedzwa yekucheka kuyedza panguva imwe chete kuti ive nechokwadi chemuchina we 3D machining huchokwadi uye kurongeka kwedenderedzwa.

Muchina chishandiso chekushandisa nharaunda

1.1 Equipment zvinodiwa zvakatipoteredza

Kuchengeta mwero wenguva dzose we ambient tembiricha chinhu chakakosha pakunyatso machining.

(1) Inowanikwa ambient tembiricha i -10 ℃ ~ 35 ℃. Kana ambient tembiricha iri 20 ℃, mwando unofanira kuva 40 ~ 75%.

(2) Kuti uchengetedze kurongeka kwechishandiso chemuchina mukati meiyo yakatarwa, tembiricha yakakwana inodiwa kuve 15 ° C kusvika 25 ° C nemusiyano wetembiricha.

Haifanirwe kudarika ± 2 ℃ / 24h.

1.2 Simba rekupa magetsi: 3-phase, 380V, voltage fluctuation mukati ± 10%, magetsi emagetsi: 50HZ.

1.3 Kana magetsi ari munzvimbo yekushandiswa asina kugadzikana, mudziyo wemuchina unofanirwa kuve wakashongedzerwa nemagetsi emagetsi kuti ive nechokwadi chekushanda kwakajairika kwechishandiso chemuchina.

1.4. Chishandiso chemuchina chinofanirwa kuve chakavimbika chekudzika: waya yekugadzika waya yemhangura, waya yacho haifanire kunge iri pasi pe10mm², uye kuramba kwepasi kuri pasi pe4 ohms.

1.5 Kuti uve nechokwadi chekushanda kwakajairika kwemidziyo, kana mhepo yakamanikidzwa yemhepo sosi ikatadza kuzadzisa zvinodiwa nemhepo sosi, seti yemidziyo yekuchenesa mhepo (dehumidification, degreasing, kusefa) inofanira kuwedzerwa pamberi pe kupinza mweya yemushini.

1.6. Midziyo yacho inofanirwa kuchengetedzwa kure kubva kune yakananga zuva, vibration uye kupisa masosi, uye kure neakakwira-frequency jenareta, emagetsi welding michina, nezvimwe, kuitira kudzivirira kutadza kwekugadzira muchina kana kurasikirwa kweiyo muchina.

Pamberi & Mushure meSevhisi

1) Pamberi peSevhisi

Kuburikidza nekudzidza chikumbiro uye ruzivo rwakakosha kubva kune vatengi uye mhinduro kune mainjiniya edu, Bossman Technical timu ine basa rekukurukurirana kwehunyanzvi nevatengi uye kugadzira mhinduro, kubatsira mutengi mukusarudza yakakodzera machining mhinduro nemichina yakakodzera.

2) Mushure meSevhisi

A. Muchina une waranti yegore rimwe uye wakabhadhara kuchengetedza kwehupenyu hwese.

B.Munguva yewaranti yegore rimwe chete mushure mekunge muchina wasvika pachiteshi chengarava, BOSSMAN ichapa mahara uye panguva yakakodzera masevhisi ekugadzirisa zvikanganiso zvakasiyana-siyana zvisiri-zvakaitwa nemunhu pamushini, uye panguva yakakodzera kutsiva marudzi ese ezvisiri-zvinokuvadza zvikamu zvemahara. of charge . Kutadza kunoitika panguva yewaranti kuchagadziriswa pamutengo wakakodzera.

C.Technical tsigiro mumaawa makumi maviri nemana pamhepo, TM, Skype, E-mail, kugadzirisa hama mibvunzo nenguva. kana isingagadziriswe, BOSSMAN inokurumidza kuronga kuti mushure mekutengesa-injiniya kuti asvike pa-saiti kuti igadziriswe, mutengi anoda kubhadhara VISA, matikiti endege uye pekugara.

Nzvimbo yeMutengi