Mashanu-axis vertical machining centre CBS akatevedzana

Features

1.Main kuita zvakanakira

1.1.I X-axis inotora tekinoroji yekutyaira yakananga, Y-axis inotora tekinoroji yakanangana nedhiraivha uye synchronous control, ine yakakwirira thrust, yakaderera ruzha, kukurumidza kupindura kukurumidza, uye yakanakisa simba rekuita. Iwo matatu-axis yeX/Y/Z ese anotora yakakwirira-chaiyo mutsara grating mhinduro, ine yakakwira chinzvimbo

1.2.Iyo yepamusoro-torque torque motokari inotyaira A-axis uye C-axis kutenderera, ine zero transmission chain, zero backlash, uye kuomarara kwakanaka; iyo yepamusoro-chaiyo angle encoder inowana chaiyo chinzvimbo

1.3.The spindle inotora yakakwirira-speed yemagetsi spindle chimiro nehupamhi hwepamusoro uye ruzha rushoma.

2.High-rigidity bhiriji chimiro

2.1.The CBS series inotora bhiriji rekugadzirisa marongerwo, uye X/Y/Z inobudirira inogara ichifamba, iyo isingakanganisi nehuremu hweA/C axis.

2.2.I A / C axis inoshanda yakazvimiririra, uye uremu hwechishandiso hahuna kukanganisa mamwe matatu axis.

2.3.Gantry chimiro uye swing uye tafura inotenderera inotsigirwa kumativi ose maviri inogona kuchengetedza yakakwirira-yakanyatsogadziriswa kwenguva yakareba.

3.Kushanda kutendeuka kushanda

4.Yakakwira-kumhanya uye yakakwirira-yakaomarara tafura inotenderera inoona inobudirira kugaya uye kushandura composite kugadzirisa.

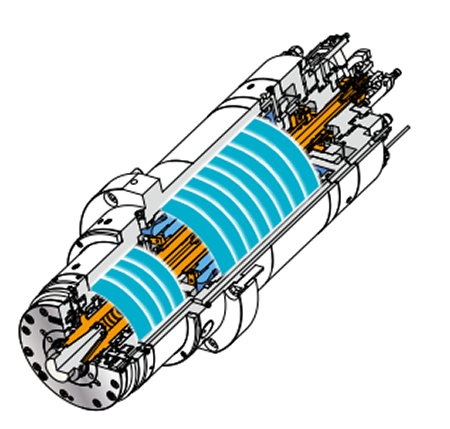

Iyo chaiyo shanu-axis inotenderera tafura yakanangana neiyo torque mota inoshandiswa muCNC muchina maturusi uye inogona kuita mashanu-axis panguva imwe chete kugadzirisa. Iine zvakanakira kumhanya kwepamusoro, kunyatsojeka, kugadzikana uye kuvimbika, uye kushanda kuri nyore.

5.Kuchengetedza yakakwirira-chaiyo machining spindles

Mastering core tekinoroji uye yakazvimirira kugadzira spindles

Oturn ine hunyanzvi hwetekinoroji uye inokwanisa kugadzira, kugadzira uye kuunganidza masipidhi. Iine 1000m2 inogara tembiricha workshop uye yakaomesesa modular yekugadzira modhi, Oturn spindles ane hunhu hwekuoma kwakakwira, kumhanya, simba rakakura, torque yakakwirira uye kuvimbika kwakanyanya.

Iyo yakazvimiririra yakagadzirwa HSKE40/HSKA63/HSKA100 yakavakirwa-mukati spindle inogamuchirwa. Mukati meiyo spindle kutenderera renji, iyo vibration uye vibration inobviswa kuti iwane yakagadzikana yakagadzikana mune yakakwirira-kumhanya uye kwenguva refu kugadzirisa. Iyo spindle inoshandisa kumanikidzwa kutonhora kutonhora mota uye kumberi nekumashure mabhengi.

6.Built-in motor structure

Nekubvisa giya rekutyaira, vibration panguva yekumhanya-mhanya kutenderera kunogona kudzikiswa, nekudaro kuvandudza iko kurongeka kwemushini wepamusoro uye kuwedzera hupenyu hwechishandiso.

7.Spindle tembiricha manejimendi

Nekutenderedza kutonhora-inodzorwa nemafuta ekutonhorera, iyo yekupisa yekupisa ye spindle inokonzerwa nekupisa kunoitwa nechikamu chimwe nechimwe inogona kudzvinyirirwa, nekudaro ichidzivirira shanduko mukugadzirisa machining.

8.Kutungamira nyika mune mutsara mota

Linear motors

8.1.Equipped with linear motor drive, hapana mechanical contact panguva yekufamba, hapana mechanical kurasikirwa, hapana backlash transmission, uye kukurumidza kupindura nokukurumidza.

8.2.Absolute optical scale for full closed-loop control.

Absolute grating mutongi, nanometer-level yekuona kurongeka, kugadzirisa kusvika 0.05μm, kuwana yakazara yakavharwa-loop control.

9.Excellent ergonomic design

Kubva pane ergonomic dhizaini, zviri nyore kune vashandisi kushandisa uye inovandudza kushanda uye kuchengetedza.

9.1.Kusvikika kwakanaka

Kuti uvandudze kushanda kwekuwana bhenji rekushanda, chivharo chiri pazasi pegonhi rekushanda chinodzoserwa kudivi rebasa rekushanda kuti ive nechokwadi chekuti nzvimbo yekushanda yakakwana.

9.2.Iwindo guru rekucherechedza nyore kwekugadzirisa

Ihwindo hombe rinoita kuti zvive nyore kutarisa mamiriro ekugadzirisa eiyo workpiece. Kunyanya, kugara uchisimbisa mamiriro ekucheka uye shanduko mukushanda panguva yekugadziriswa mashandiro anogona zvakare kupedzwa nyore, kuvandudza kushanda zvakanaka.

9.3.Kugadziriswa kwepakati pekugadzirisa zvikamu

Kuti uvandudze kushanda kwekuwana bhenji rekushanda, chivharo chiri pazasi pegonhi rekushanda chinodzoserwa kudivi rebasa rekushanda kuti ive nechokwadi chekuti nzvimbo yekushanda yakakwana.

9.4.Wide oparesheni gonhi kuti nyore kuwana ne crane

Paunenge uchiita mabasa akadai sekugadzirisa workpiece, basa revashandi rinogona kuderedzwa, uye panguva imwechete, pane nzvimbo yakakwana yekushanda kana uchishandisa crane.

9.5.Pleasant uye ushamwari kushanda panel

Iyo inotenderedzwa yekushanda pani inoenderana nekukwirira kwemuviri wemunhu inobvumira mushandisi kuti ashande uye kuronga muchina mune yakasununguka posture.

Zvidimbu zvehunyanzvi

| Item | CBS200 | CBS200C | CBS300 | CBS300C | CBS400 | CBS400C | |

| Travel | X/Y/Z axis kufamba | 300*350*250 | 300*350*250 | 460*390*400 | |||

| Distance from spindle face to worktable center | 130-380 | 130-380 | 155-555 | ||||

| Spindle | Spindle taper | E40 | E40 | E40 | |||

| Max.spindle speed | 30000 | 30000 | 30000 | ||||

| Spindle mota simba (inoenderera/S325%) | 11/13.2 | 11/13.2 | 11/13.2 | ||||

| Spindle mota torque (inoenderera / S325%) | 11.5/13.8 | 11.5/13.8 | 11.5/13.8 | ||||

| Feed |

Kukurumidza kumhanya kwe X/Y/Z axis (m/min)

| 48/48/48 | 48/48/48 | 30/30/30 | |||

| Kucheka chikafu (mm/min) | 1-24000 | 1-24000 | 1-12000 | ||||

| Rotary table | Rotary tafura dhayamita | 200 | 300 | 400 | |||

| Inobvumirwa mutoro uremu | 30 | 20 | 40 | 25 | 250 | 100 | |

| A-axis tilting angle | ±110° | ±110° | ±110° | ||||

| C-axis kutenderera | 360° | 360° | 360° | ||||

| A-axis rated/max.speed | 47/70 | 47/70 | 30/60 | ||||

| A-axis Rated/max.torque | 782/1540 | 782/1540 | 940/2000 | ||||

| C-axis rated/max.speed | 200/250 | 1500/2000 | 200/250 | 1500/2000 | 100/150 | 800/1500 | |

| C-axis rated/max.torque | 92/218 | 15/30 | 92/218 | 15/30 | 185/318 | 42/60 | |

| A-axis positioning kurongeka/kudzokororazve | 10/6 | 10/6 | 10/6 | ||||

| C-axis yekumisikidza kurongeka / kudzokorora | 8/4 | 8/4 | 8/4 | ||||

| ATC | Tool magazini kukwanisa | 16 | 16 | 26 | |||

| Tool max. dhayamita/ urefu | 80/200 | 80/200 | 80/200 | ||||

| Max.tool uremu | 3 | 3 | 3 | ||||

| Chishandiso chekuchinja nguva (chokushandisa kune chishandiso) | 4 | 4 | 4 | ||||

| Tatu- axis | X-axis gwara (linear gwara hupamhi/ nhamba yemasiraidhi) | 30/2 | 30/2 | 35/2 | |||

| X-axis gwara (linear gwara hupamhi/ nhamba yemasiraidhi) | 35/2+30/2 | 35/2+30/2 | 45/2 | ||||

| Z-axis gwara (linear gwara hupamhi/ nhamba yemasiraidhi) | 25/2 | 25/2 | 35/2 | ||||

| X-axis linear mota simba (inoenderera/max.) | 1097/2750 | 1097/2750 | φ40×10 (siruru) | ||||

| Y-axis mutsara mota simba (inoenderera/max.) | 3250/8250 | 3250/8250 |

| ||||

| Z-axis linear mota simba (inoenderera/max.) | 1033/1511 | 1033/1511 |

| ||||

| Kururama | Positioning kururama | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Kudzokorora | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Power source | Simba rekupa simba | 25 | 30 | 25 | 30 | 30 | 35 |

| Air pressure | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Saizi yemuchina | Saizi yemuchina | 1920*3030*2360 | 1920*3030*2360 | 2000*2910*2850 | |||

| Saizi yemuchina (kusanganisira chip conveyor nemimwe midziyo yeperipheral) | 3580*3030*2360 | 3580*3030*2360 | 3360*2910*2850 | ||||

| Kurema | 4.8T | 4.8T | 5T | ||||

| Item | CBS500 | CBS500C | CBS650 | CBS650C | CBS800 | CBS800C | |

| Travel | X/Y/Z axis kufamba | 500*600*450 | 650*800*560 | 800*910*560 | |||

| Distance from spindle face to worktable center | 130-580 | 110-670 | 100-660 | ||||

| Spindle | Spindle taper | A63 | A63 | A63 | |||

| Max.spindle speed | 20000 | 20000 | 20000 | ||||

| Spindle mota simba (inoenderera/S325%) | 30/34 | 30/34 | 30/34 | ||||

| Spindle mota torque (inoenderera / S325%) | 47.7/57.3 | 47.7/57.3 | 47.7157.3 | ||||

| Feed | Kukurumidza kumhanya kwe X/Y/Z axis (m/min)

| 48/48/48 | 48/48/48 | 48/48/48 | |||

| Kucheka chikafu (mm/min) | 1-24000 | 1-24000 | 1-24000 | ||||

| Rotary table | Rotary tafura dhayamita | 500 | 650 | 800 | |||

| Inobvumirwa mutoro uremu | 600 | 240 | 800 | 400 | 1000 | 400 | |

| A-axis tilting angle | ±110° | ±110° | ±110° | ||||

| C-axis kutenderera | 360° | 360° | 360° | ||||

| A-axis rated/max.speed | 60/80 | 40/8C | 40/80 | ||||

| A-axis Rated/max.torque | 1500/4500 | 3500/7000 | 3500/7000 | ||||

| C-axis rated/max.speed | 80/120 | 600/1000 | 50/80 | 450/800 | 50/80 | 450/800 | |

| C-axis rated/max.torque | 355/685 | 160/240 | 964/1690 | 450/900 | 964/1690 | 450/900 | |

| A-axis positioning kurongeka/kudzokororazve | 10/6 | 10/6 | 10/6 | ||||

| C-axis yekumisikidza kurongeka / kudzokorora | 8/4 | 8/4 | 8/4 | ||||

| ATC | Tool magazini kukwanisa | 25 | 30 | 30 | |||

| Tool max. dhayamita/ urefu | 80/300 | 80/300 | 80/300 | ||||

| Max.tool uremu | 8 | 8 | 8 | ||||

| Chishandiso chekuchinja nguva (chokushandisa kune chishandiso) | 4 | 4 | 4 | ||||

| Tatu- axis | X-axis gwara (linear gwara hupamhi/ nhamba yemasiraidhi) | 35/2 | 45/2 | 45/2 | |||

| X-axis gwara (linear gwara hupamhi/ nhamba yemasiraidhi) | 45/2 | 45/2 | 45/2 | ||||

| Z-axis gwara (linear gwara hupamhi/ nhamba yemasiraidhi) | 35/2 | 35/2 | 35/2 | ||||

| X-axis linear mota simba (inoenderera/max.) | 2167/5500 | 3250/8250 | 3250/8250 | ||||

| Y-axis mutsara mota simba (inoenderera/max.) |

|

|

| ||||

| Z-axis linear mota simba (inoenderera/max.) | 2R40*20 (siruru) | 2R40*20 (siruru) | 2R40*20 (siruru) | ||||

| Kururama | Positioning kururama | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Kudzokorora | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Power source | Simba rekupa simba | 40 | 45 | 55 | 70 | 55 | 70 |

| Air pressure | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ≥0.6Mpa ≥400L/min | ||||

| Saizi yemuchina | Saizi yemuchina | 2230*3403*3070 | 2800*5081*3500 | 2800*5081*3500 | |||

| Saizi yemuchina (kusanganisira chip conveyor nemimwe midziyo yeperipheral) | 2230*5540*3070 | 2800*7205*3500 | 2800*7205*3500 | ||||

| Kurema | 11T | 15T | 15.5T | ||||

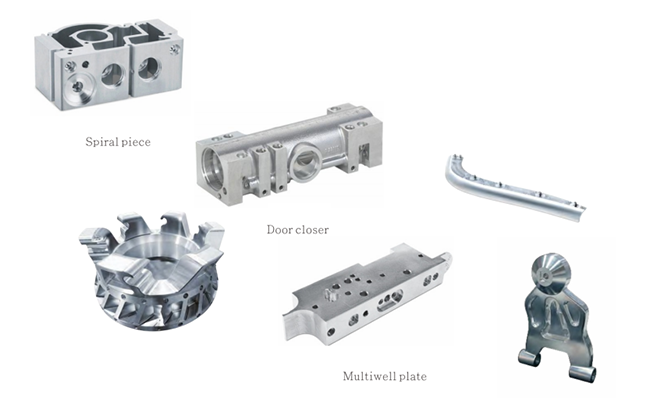

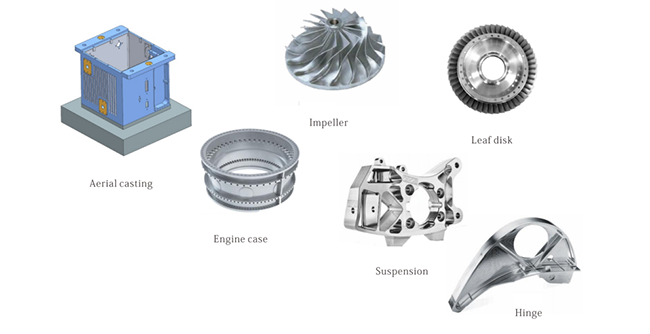

Processing Cases

1.Automotive Industry

2.Muchadenga

3.Kuvaka Michina