E30 CNC Cylindrical Kukuya Muchina WeKucheka Zvishandiso

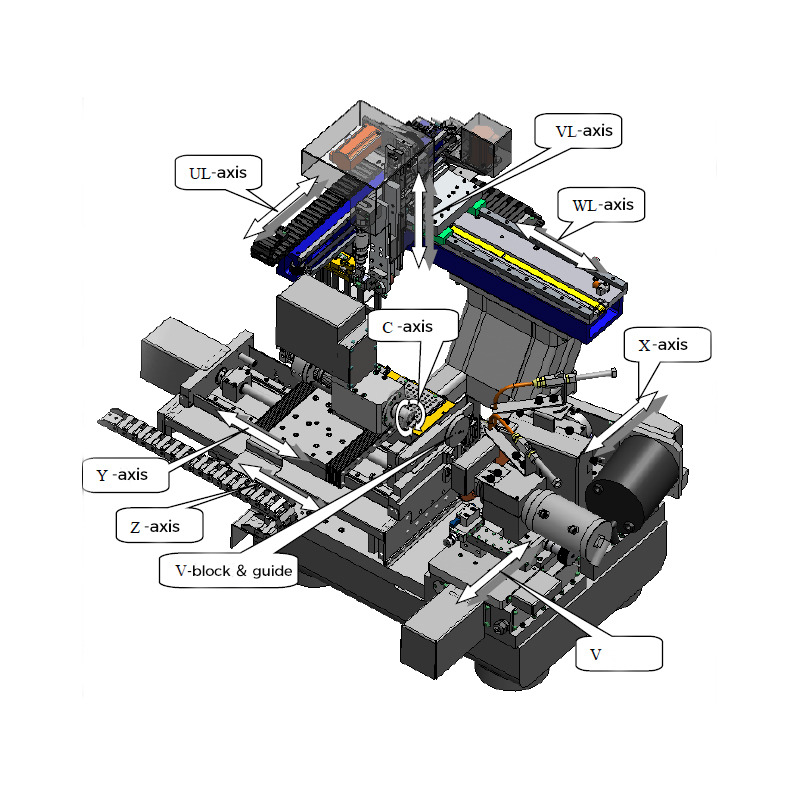

Main chimiro dhizaini yemuchina

Sarudzo yekushandisa

Rudzi rwekushandisa: milling cutter, drill bit, reamer uye akasiyana akakwira-chaiyo zvikamu kugadzirisa.

Kugadziriswa kwemhando: dhayamita yezvigadzirwa zvakagadziriswa: Φ3~Φ20mm, kureba kwezvigadzirwa zvakagadziriswa: 120mm (otomatiki), 330mm (manual).

Kugadzirisa maitiro: panguva imwe chete kukuya kwemavhiri akaomesesa maviri ekukuya, imwe-nguva kugadzirisa uye kugadzira.

Machine sumo

1. Chimiro chemubhedha:

2. Sheet simbi yemuchina wese: muchina wese une chimiro chakavharirwa zvizere, uye iyo huru furemu yakapatsanurwa kubva kune yekunze chivharo kudzivirira kuzunguzika.

3. Kudzora system: NEWCON

4. Nheyo yekucheka:

• X-axis (coarse grinding wheel mechanism): ziva mafambiro anodzokorodza evhiri rekukuya mugwara reX-axis;

• V-axis (yakanaka grinding wheel mechanism): cherechedza mafambiro ekudzoka kwegumbo rakanaka rekukuya muV-axis nzira;

• Y-axis (Y-axis feed mechanism): ziva kudzokororwa kwekufamba kweiyo worktable munzira yeY-axis;

• C axis (kushanda musoro kutenderera nzira): ziva kutenderera kutenderera kwemusoro unoshanda munzira yeC axis :;

• UL axis, VL axis uye WL axis (manipulator pick-and-place mechanism): ziva kudzokororwa kwekufamba kwechidhiraivho munzira yakachinjika uye yakatwasuka;

• Kutungamira vhiri uye V-block rutsigiro: Inobatsira pakupedzwa kwekugadzira machining.

1. Zvikamu zvinofamba: X axis, V axis, Y axis, WL axis, UL axis, VL axis, gidhi vhiri mashandiro, ruoko rwokugadzira, hysteresis kugadzirisa

2. Workpiece spindle: Chuangyun self-made spindle

3. Kukuya spindle: Xiamen Tungsten Motor

4. Mafuta emuchina wese: mazamu emafuta anochengeterwa axis yega yega uye anozorwa nguva nenguva.

5. Kudyisa nzira: matatu-axis manipulator kudya

Zvido zvehunyanzvi

| control method | Mabhatani ekunze, touch screen | |

| Ratidza nzira | Bata skrini, mwenje wenyevero | |

| kutonhora nzira | Oiri inotonhorera | |

| kutamisa nzira | Hydraulic, pneumatic, servo mota | |

| magetsi | AC 3×380V ,50Hz | |

| Maximum yakazara simba | 25KW | |

| Dimensions | 2152×1838×2614 mm | |

| huremu hwakakura | 3050kg | |

| Kutonhora kwemafuta ekupisa | 0.6 ~ 0.8MPa | |

| barometric pressure | Yese kumanikidzwa kwemugwagwa: 5 ~ 6Bar | |

| Chuck air pressure: 2 ~ 3Bar | ||

| Nhungamiro vhiri mhepo kudzvinyirirwa: 2 ~ 2.5Bar | ||

| Gripper yemhepo nzira yekumanikidza: 1.5 ~ 4Bar | ||

| Arm air pressure: 5 ~ 6Bar | ||

| Optical chiyero chekuchenesa mweya wekumanikidza: 0.6 ~ 0.7Bar | ||

| Manipulator parameters | ||

| UL axis | Travel | 450mm |

| Kudzokorora | 0.02mm | |

| Maximum yekushandisa kumhanya | 15000mm/min | |

| VL axis | Travel | 100mm |

| Kudzokorora | 0.02mm | |

| Maximum yekushandisa kumhanya | 15000mm/min | |

| WL axis | Travel | 540mm |

| Kudzokorora | 0.02mm | |

| Maximum yekushandisa kumhanya | 15000mm/min | |

| Kugadzirisa axis parameter | ||

| Y axis | Travel | 350mm |

| Minimum Resolution Kururama | 0.0001mm | |

| X axis | Travel | 35mm |

| Minimum Resolution Kururama | 0.0001mm | |

| V axis | Travel | 35mm |

| Minimum Resolution Kururama | 0.0001mm | |

| Guide vhiri | Kutenderera chaiko: | ≤0.010mm |

| Musoro wekushanda (C axis) | Motor Power | 1.57Kw |

| Kutenderera kumhanya | ≤2000rpm | |

| Runout kururama | ≤0.002mm | |

| zvishoma kugadzirisa | 0.0001° | |

| Huru kukuya vhiri | Motor Power | 8.5KW |

| Kutenderera kumhanya | ≤5000rpm | |

| Runout kururama | ≤0.002mm | |

| dynamic balance | ≤G0.4 | |

| Fine grinding vhiri spindle | Motor Power | 1.4KW |

| Kutenderera kumhanya | ≤7950rpm | |

| Runout kururama | ≤0.002mm | |

| dynamic balance | ≤G0.4 | |

| Kukuya parameters |

|

|

| Chuck model | W20 | |

| Coarse grinding vhiri dhayamita | Ø250mm | |

| Fine grinding vhiri dhayamita | Ø150mm | |

| Workpiece Shank Diameter | Ø3-Ø12mm (otomatiki) / Ø3-Ø20mm (manyorero) | |

| Workpiece Kukuya Range | Ø0.08 - Ø20mm | |

| workpiece urefu | 120mm (otomatiki) / 350mm (manyorero) | |

| Iyo yakareba yekugadzirisa kureba kwe workpiece | 330mm | |

| Kugadzirisa ekunze dhayamita runout | ≤0.003mm | |

| Kureba machining kururama | ±0.1mm | |

| Angle machining kururama | ≤0.3° | |

| Kururama kwechitarisiko | ≤Ra0.4 (pedza kugaya) | |

Standard configuration list

| 10 | CNC system | NEWC0N | 1 |

| 20 | servo mota | NEWC0N | 8 |

| 30 | server Driver | NEWC0N | 4 |

| 40 | Operation panel / ruoko vhiri | NEWC0N | 1 |

| 50 | High precision kushanda musoro module | GESAC | 1 |

| 60 | Yepamusoro-chaiyo yemagetsi spindle (1.4KW) | GESAC | 1 |

| 70 | Yakakwira chaiyo mota (7.1KW) | GESAC | 1 |

| 80 | High Precision Mechanical Spindle | GESAC | 1 |

| 90 | Precision njanji | Schneeberger | 10 |

| 100 | Precision Yakayambuka Roller Linear Way | Schneeberger | 4 |

| 110 | Precision Ball Screw | NSK | 4 |

| 120 | Kushanda uye kugadzirisa simulation software (yakajairwa nhanho musiyano, spherical, nezvimwewo) | GESAC | 1 |

| 130 | Inverter | GESAC | 1 |

| 140 | Inverter | GESAC | 1 |

| 150 | touch screen | 19寸ELO | 1 |

| 160 | Muchina chishandiso chekuchengetedza gonhi rekiyi mudziyo | Jinzhong | 1 |

| 170 | sensor | Baumer | 3 |

| 180 | kuyerera sensor | Yifumen | 1 |

| 190 | Zvikamu zvemagetsi | Schneider | 1 |

| 200 | Pneumatic Components | CKD | 1 |

| 210 | Waya uye Cable | ComCab | 1 |

| 220 | Rack air conditioner | GESAC | 1 |

| 230 | Precision pressure vhiri Ø92x8 | GESAC | 1 |

| 240 | Precision pressure vhiri Ø92x15 | GESAC | 1 |

| 250 | Chuck W20 D4 | GESAC | 1 |

| 260 | Standard tireyi D4 | GESAC | 3 |

| 260 | High-precision inoenderana neV-block (3-6) * 10 | GESAC | 1 |

| 280 | High precision kugaya vhiri flange (kukurumidza shanduko rudzi) | GESAC | 2 |

| 290 | Seti yakazara yezvigunwe zve manipulator | GESAC | 1 |

Machine maitiro

7 CNC mbezo, 4 CNC matemo anoshandiswa munzvimbo yekugadzirisa, iyo inogona kuona otomatiki kurodha uye kurodha, batch isina kurongwa kugadzirwa.

Machining kunyatsoita uye kushanda zvakanaka kwemidziyo yemuchina

1. Iyo radial runout yeworkpiece iri mukati me 0.003mm;

2. Kururama kwehukuru 2.0 inodzorwa mukati me ± 0.005mm;

3. Kutenderera kweworkpiece iri mukati me 0.003mm;

4. Kushata kwepamusoro < Ra0.4;