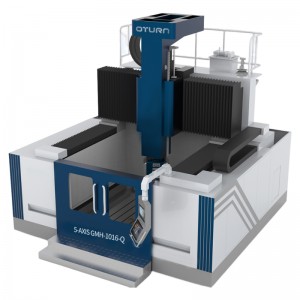

CNC Profile Machining Center

CNC Profile Machining Center

CNC Drilling Machine

Machine Features

Bosm DC seriesCNC yekuchera uye milling michinaanonyanya kushandiswa kudhiraivha kudhiraivha uye kubatika kwezvishandiso zvine mutsara wezvinhu upamhi mukati meiyo inoshanda renji. Kuburikidza negomba uye gomba rebofu rinogona kuroverwa pane imwechete zvinhu zvikamu uye zvinhu zvinoumbwa. Muchina wekugadzirisa neCNC controller, kushanda kwacho kuri nyore kwazvo. Inogona kuona otomatiki, yakanyanya kurongeka, akawanda akasiyana uye kugadzirwa kwakawanda.

Kuti isangane nezvinodiwa zvekugadzirisa zvevashandisi vakasiyana, Kambani yedu yakagadzira zvakasiyana-siyana zvakapedzwa zvigadzirwa.Inogona zvakare kugadzirwa uye kugadziridzwa zvinoenderana nezvinodiwa chaizvo zvevashandisi.

Machine Structure

Midziyo iyi inonyanya kuumbwa netafura yemubhedha, mobile gantry, mobile saddle, drilling uye kugaya simba musoro, otomatiki lubrication mudziyo uye kudzivirira mudziyo, inotenderera inotonhorera mudziyo, digital control system, hydraulic system, magetsi system, nezvimwe. kurongeka uye kudzokororwa kwenzvimbo.

1. Mubhedha &pabasa:

Mubhedha wemuchina wakaiswa welded simbi chimiro zvikamu, uye iyo huru furemu inogadziriswa nesimbi chimiro zvikamu. Mushure mekunge kushushikana kwemukati kwabviswa nekugadzirwa kwekuchembera kupisa kurapwa, ine yakanaka dynamic uye static rigidity uye haina deformation. Iyo worktable yakagadzirwa nesimbi yekukanda HT250. Iyo worktable inogona kushandiswaclamping workpieces. Iyo inogona zvakare kuve yakashongedzerwa nepneumatic fixture, iyo iri nyore uye nekukurumidza kune clamping workpieces,. Iyo yakanyanya kutakura kugona kweiyo worktable ndeye 1 ton. Rutivi rwekumusoro kuruboshwe rwemubhedha rwakaiswa vertically neaviri ekupedzisira-yepamusoro-soro inotakura inotenderedza linear giraidhi pairi uye chaiyo rack. Iyo gantry mota inofambiswa neAC servo system uye rack system muX kutungamira. Mabhoti anogadziriswa akagoverwa pasi pemubhedha, izvo zvinogona kugadzirisa nyore nyore chiyero chetafura yemubhedha.

2. Kufambisa cantilever:

Iyo inofambiswa cantilever gantry ine cast iron chimiro inogadziriswa mushure mekubvisa kushushikana kwemukati neyakagadzirwa kuchembera kupisa kurapwa, ine yakanaka inoshanduka uye static rigidity uye isina deformation. Maviri anotenderedza mutsara ekutungamira maviri ane ultra-yakakwirira kutakura simba akaiswa kumberi nekumusoro mativi egantry. Iyo mutsara inotenderedza dhairekitori ine ultra-yakakwirira kutakura simba, seti yechaiyo bhora screw uye servo mota inoiswa pamusoro kuita kuti siraidhi ndiro yesimba remusoro rifambe munzira yeY-axis. Musoro wesimba rekuchera unoiswa pane inotsvedza ndiro yemusoro wesimba. Kufamba kwegantry kunoonekwa nekutenderera kwebhora screw inotungamirwa ne servo mota kuburikidza nekubatanidza.

3. Chisharo chekufamba:

Chisharo chinotsvedza inhengo yesimbi. Maviri anotenderedza mutsara ekutungamira mapeya ane Ultra-yakakwirira kubereka simba, seti yechaiyo bhora screw uye servo mota inoiswa pachisadhi chinotsvedza kutyaira musoro wesimba rekudhiraivha kuti ufambe munzira z-axis, inogona kuona kukurumidza kumberi, shanda mberi, nekukurumidza kumashure uye kumira kwemusoro wesimba. Iyo ine mabasa e otomatiki chip breaking, chip kubvisa uye kumbomira.

Special servo spindle mota inoshandiswa kuchera simba musoro. Iyo yakakosha chaiyo spindle inofambiswa neinothed synchronous bhandi kuti ione inosiyana frequency stepless kumhanya shanduko. Iyo yekudya inofambiswa ne servo mota uye bhora screw.

Iyo y-axis inogona kubatanidzwa uye kudzorwa nehafu yakavharwa loop, iyo inogona kuona mutsara uye denderedzwa kududzira. Iyo huru shaft inopera ndeye er taper hole clamping drill kana milling cutter, ine chaiyo yakakwira, kukurumidza kucheka, pneumatic chishandiso shanduko basa, sarudzo ine hat type tool magazine, chishandiso magazini inokwana masere, shanduko yezvishandiso iri nyore, yakakwirira degree re automation. ye manual processing.

5. Otomatiki lubrication mudziyo uye kudzivirira mudziyo:

Muchina uyu wakashongedzerwa neotomatiki lubrication mudziyo, unogona kungoisa mafuta pairi inofamba senge njanji, lead screw uye rack. Iyo x-axis uye Y-axis yemuchina chishandiso yakashongedzerwa neguruva-chiratidzo chekudzivirira chivharo, uye iyo isina mvura inoputika baffle inoiswa yakatenderedza worktable.

6. KND Control System:

6.1. Ne chip breaking function, chip breaking time uye chip breaking cycle inogona kuiswa pane man-machine interface.

6.2. Withbasa rekusimudza mudziyo, chishandiso chekusimudza kureba chinogona kusetwa pane murume-muchina interface. Paunenge uchichera kusvika paurefu uhwu, chibooreso chinokurumidza kusimudzwa kumusoro kwechishandiso, ipapo chip chinokandwa, chobva chakurumidza kuenda kunzvimbo yekuchera uye inoshandurwa otomatiki kuita basa repamberi.

6.3. Iyo centralized operation control box uye handheld unit ine CNC system, USB interface uye LCD skrini. Kuti ufambise hurongwa, kuchengetedza, kuratidza uye kutaurirana, iyo interface yekushanda ine mabasa emunhu-muchina dialogue, kukanganisa kukanganisa uye otomatiki alarm.

6.4. Iyo midziyo ine basa rekutarisa uye recheck yegomba chinzvimbo usati wagadzira, saka mashandiro acho ari nyore.

Tsanangudzo

| Model | BOSM-DC60050 | |

| Max. workpiece saizi | Kureba × upamhi (mm) | 2600×500 |

| Vertical Ram drilling simba musoro | Huwandu (chidimbu) | 1 |

| Spindle taper gomba | BT40 | |

| Kuchera dhayamita (mm) | Φ2-Φ26 | |

| Spindle kumhanya (R / min) | 30-3000 | |

| Spindle simba (kw) | 15 | |

| Chinhambwe chiri pakati pemhino yechirungu netafura yekushanda (mm) | 150-650mm | |

| X-axis (kufamba kwakatarisana) | Kunyanya sitiroko (mm) | 500 |

| X-axis inofamba kumhanya (M / min) | 0~9 | |

| X-axis servo mota simba (kw) | 2.4*1 | |

| Y-axis(column longitudinal movement) | Kunyanya sitiroko (mm) | 2600 |

| Y-axis inofamba kumhanya (M / min) | 0~9 | |

| Simba rey-axis servo mota (kw) | 2.4*1 | |

| Z axis (Yakamira gondohwe rekudya kufamba) | Kunyanya sitiroko (mm) | 500 |

| Kufamba kumhanya kweZ axis (M / min) | 0~8 | |

| Z-axis servo mota simba (kw) | 1 × 2.4 nebhureki | |

| Dimension yemuchina | Kureba × upamhi × kureba (mm) | 5400×2180×2800 |

| Positioning kururama | X/Y/Z | ± 0.05/300mm |

| Kudzokororwa kwechokwadi chinzvimbo | X/Y/Z | ± 0.025/300mm |

| Gross huremu (t) | 4.5 | |

Quality Inspection

Muchina wega wega wakarongedzerwa nelaser interferometer kubva kuUnited Kingdom RENISHAW kambani, iyo inonyatso ongorora uye nekubhadhara zvikanganiso zvepitch, backlash, kurongeka kwenzvimbo, uye inodzokororwa yekumisikidza kurongeka kuti ive nechokwadi chekusimba kwemuchina, kugadzikana, uye kugadzirisa iko kurongeka. . Bhora bhawa bvunzo Muchina wega wega unoshandisa bhora rekuyedza kubva kuBritish RENISHAW kambani kugadzirisa chokwadi denderedzwa nemazvo uye muchina geometric nemazvo, uye kuita ongororo yekucheka denderedzwa panguva imwe chete kuti ive nechokwadi chemuchina we3D machining huchokwadi uye denderedzwa rechokwadi.

Muchina chishandiso chekushandisa nharaunda

1.1 Equipment zvinodiwa zvakatipoteredza

Kuchengeta mwero wenguva dzose we ambient tembiricha chinhu chakakosha pakunyatso machining.

(1) Inowanikwa ambient tembiricha i -10 ℃ ~ 35 ℃. Kana ambient tembiricha iri 20 ℃, mwando unofanira kuva 40 ~ 75%.

(2) Kuti uchengetedze kurongeka kwechishandiso chemuchina mukati meiyo yakatarwa, tembiricha yakakwana inodiwa kuve 15 ° C kusvika 25 ° C nemusiyano wetembiricha.

Haifanirwe kudarika ± 2 ℃ / 24h.

1.2 Simba rekupa magetsi: 3-phase, 380V, voltage fluctuation mukati ± 10%, magetsi emagetsi: 50HZ.

1.3 Kana magetsi ari munzvimbo yekushandiswa asina kugadzikana, mudziyo wemuchina unofanirwa kuve wakashongedzerwa nemagetsi emagetsi kuti ive nechokwadi chekushanda kwakajairika kwechishandiso chemuchina.

1.4. Chishandiso chemuchina chinofanirwa kuve chakavimbika chekudzika: waya yekugadzika waya yemhangura, waya yacho haifanire kunge iri pasi pe10mm², uye kuramba kwepasi kuri pasi pe4 ohms.

1.5 Kuti uve nechokwadi chekushanda kwakajairika kwemidziyo, kana mhepo yakamanikidzwa yemhepo sosi ikatadza kuzadzisa zvinodiwa nemhepo sosi, seti yemidziyo yekuchenesa mhepo (dehumidification, degreasing, kusefa) inofanira kuwedzerwa pamberi pe kupinza mweya yemushini.

1.6. Midziyo yacho inofanirwa kuchengetedzwa kure kubva kune yakananga zuva, vibration uye kupisa masosi, uye kure neakakwira-frequency jenareta, emagetsi welding michina, nezvimwe, kuitira kudzivirira kutadza kwekugadzira muchina kana kurasikirwa kweiyo muchina.

Pamberi & Mushure meSevhisi

1) Pamberi peSevhisi

Kuburikidza nekudzidza chikumbiro uye ruzivo rwakakosha kubva kune vatengi uye mhinduro kune mainjiniya edu, Bossman Technical timu ine basa rekukurukurirana kwehunyanzvi nevatengi uye kugadzira mhinduro, kubatsira mutengi mukusarudza yakakodzera machining mhinduro nemichina yakakodzera.

2) Mushure meSevhisi

A. Muchina une waranti yegore rimwe uye wakabhadhara kuchengetedza kwehupenyu hwese.

B.Munguva yewaranti yegore rimwe chete mushure mekunge muchina wasvika pachiteshi chengarava, BOSSMAN ichapa mahara uye panguva yakakodzera masevhisi ekugadzirisa zvikanganiso zvakasiyana-siyana zvisiri-zvakaitwa nemunhu pamushini, uye panguva yakakodzera kutsiva marudzi ese ezvisiri-zvinokuvadza zvikamu zvemahara. of charge . Kutadza kunoitika panguva yewaranti kuchagadziriswa pamutengo wakakodzera.

C.Technical tsigiro mumaawa makumi maviri nemana pamhepo, TM, Skype, E-mail, kugadzirisa hama mibvunzo nenguva. kana isingagadziriswe, BOSSMAN inokurumidza kuronga kuti mushure mekutengesa-injiniya kuti asvike pa-saiti kuti igadziriswe, mutengi anoda kubhadhara VISA, matikiti endege uye pekugara.

Nzvimbo yeMutengi