Center Drive Lathe For Axle

Automobile axle tekinoroji kuongororwa

Esero yemota

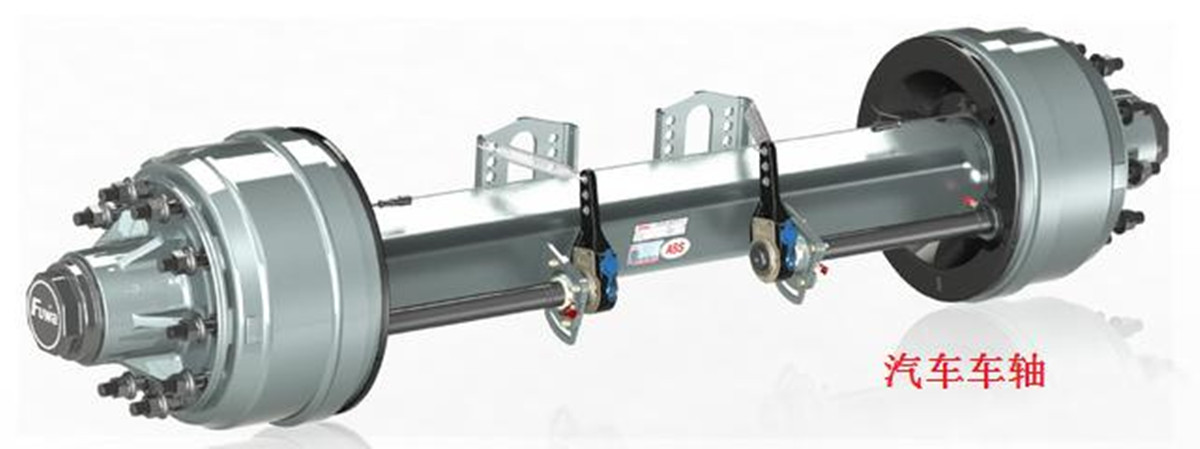

Maekisi ane mavhiri pamativi ese eiyo undercarriage (frame) akaunganidzwa anonzi maekisi emota, uye maekisi ane kutyaira anowanzo kunzi ma axles. Musiyano mukuru pakati pezviviri izvi ndewekuti kune dhiraivha pakati peekisi (axle). Mubepa iri, axle yemotokari ine dhiraivha unit inodaidzwa kunzi mota isina dhiraivha inodaidzwa kuti axle yemotokari kuratidza mutsauko.

Nekuwedzera kuri kuita kudiwa kwezvinhu uye zvekufambisa, hukuru hwema axles emota, kunyanya matrailer uye semi-trailer, mukufambisa kwehunyanzvi uye mashandiro akasarudzika ari kuramba achijeka, uye kudiwa kwemusika kwakawedzera zvakanyanya.

Iyi tekinoroji inoongorora machining maitiro eiyo axle, tariro yekubatsira vatengi kuti vasarudze akakodzera CNC muchina.

Automobile axle classification:

Mhando dzemaakisi dzakasiyana zvichienderana nerudzi rwebhureki, uye dzakakamurwa kuita: disc brake axles, dhiramu brake axles, nezvimwe.

Zvinoenderana nehukuru hweiyo shaft dhayamita chimiro, yakakamurwa kuita: American axle, German axle; etc.

Zvinoenderana nechimiro uye chimiro, yakakamurwa kuita:

iyo yose: yakasimba sikweya chubhu ekisi, hollow square chubhu ekisi, hollow round axle;

kupatsanura muviri: shaft musoro + hollow shaft tube welding.

Kubva pane zvirimo zvekugadzirisa zve axle, iyo yakasimba uye isina maaxles ine hukama nekusarudzwa kwemichina yekugadzirisa.

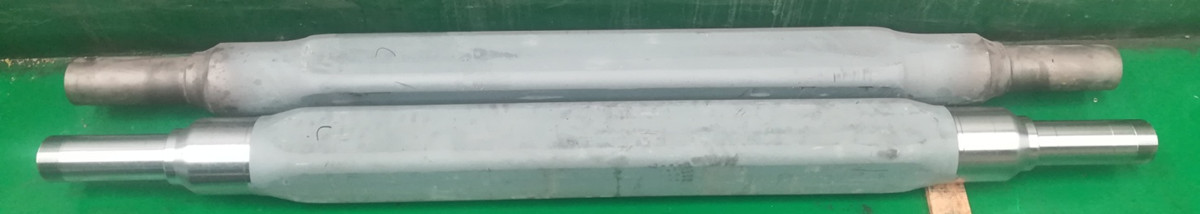

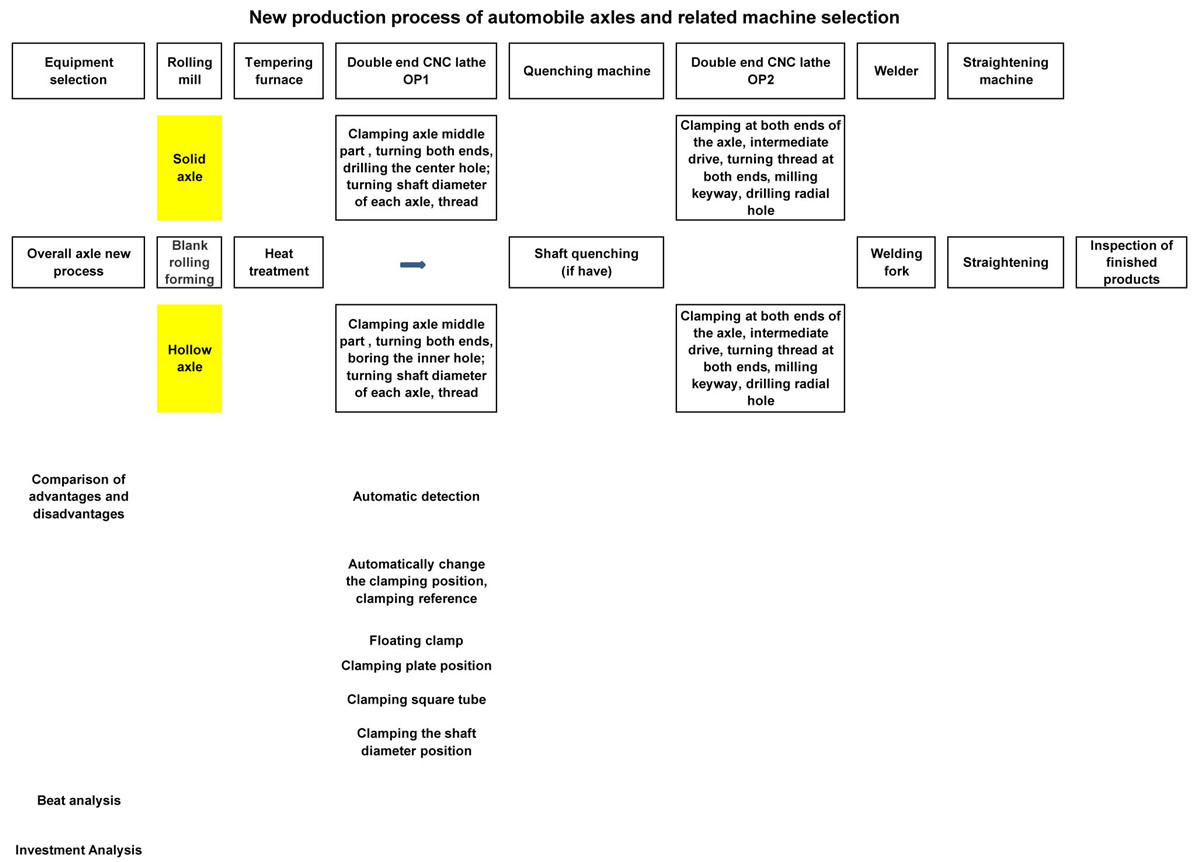

Izvi zvinotevera kuongororwa kwemaitiro ekugadzirwa kweaxle yese (zvakakamurwa kuita yakasimba uye isina hollow; square chubhu uye yakatenderedza chubhu), uye kupatsanurwa axle (yakasimba uye ine hollow shaft musoro + hollow shaft tube welding), Kunyanya, machining process. inoongororwa kuti isarudze zvirinani muchina wakakodzera.

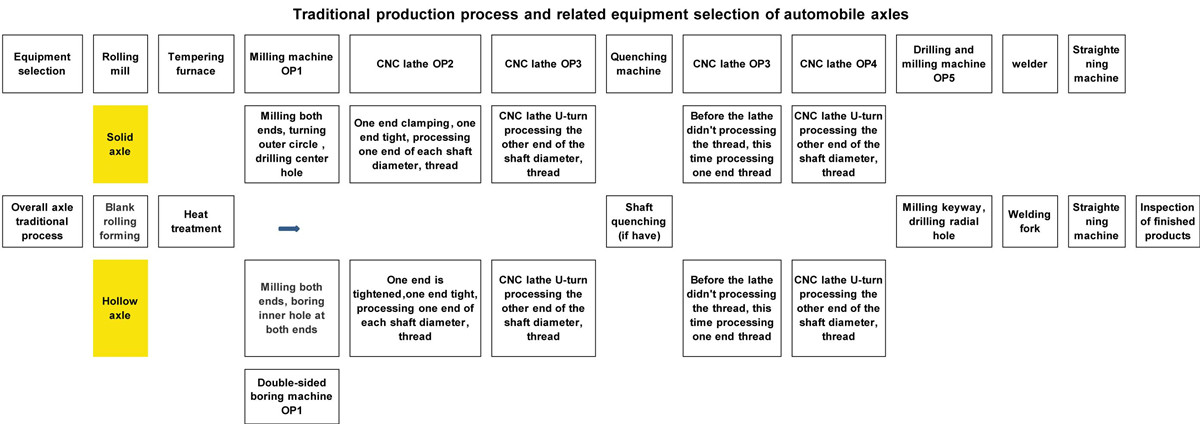

Kugadzira maitiro uye muchina wema axles emota:

1. Maitiro echinyakare ekugadzira esero rese:

Kubva pane iri pamusoro pekugadzira axle maitiro, angangoita matatu marudzi ezvishandiso zvemuchina anodiwa kuti apedze machining: muchina wekugaya kana maviri-mativi anobhowa muchina, CNC lathe, yekuchera uye muchina wekugaya, uye CNC lathe inoda kushandurwa (vamwe vatengi vane yakasarudzwa kaviri-musoro CNC lathe). Nezve tambo yekugadzirisa, kana iyo shaft dhayamita yakadzimwa, inogadziriswa mushure mekudzima; kana pasina kudzima, inogadziriswa muOP2 neOP3, uye OP4 uye OP5 sequence muchina maturusi anosiyiwa.

Kubva pamaitiro matsva ekugadzira, muchina wekugaya unoshandiswa kugadzira (solid axle) kana kaviri-sided boring muchina (hollow axle) pamwe neCNC lathe, yechinyakare OP1 milling, OP2, OP3 inotenderedza kutevedzana, uye kunyangwe OP5 kuchera uye kugaya Inogona kutsiviwa. neaviri-magumo CNC lathe OP1.

Kune maekisi akasimba uko shaft dhayamita isingade kudzimwa, zvese zviri mukati memuchina zvinogona kupedzwa mune imwe setup, kusanganisira milling kiyi grooves uye kuchera radial maburi. Kune maaxles asina mhango uko iyo shaft dhayamita isingade kudzimwa, iyo otomatiki inoshandura clamping standard inogona kuwanikwa mumuchina wemuchina, uye machining emukati anogona kupedzwa nechishandiso chemuchina mumwe.

Sarudza kaviri-yekupedzisira axle yakakosha CNC lathes kumashini maaxles anopfupisa nzira yekugadzira, uye mhando uye huwandu hwematurusi emuchina akasarudzwa achaderedzwawo.

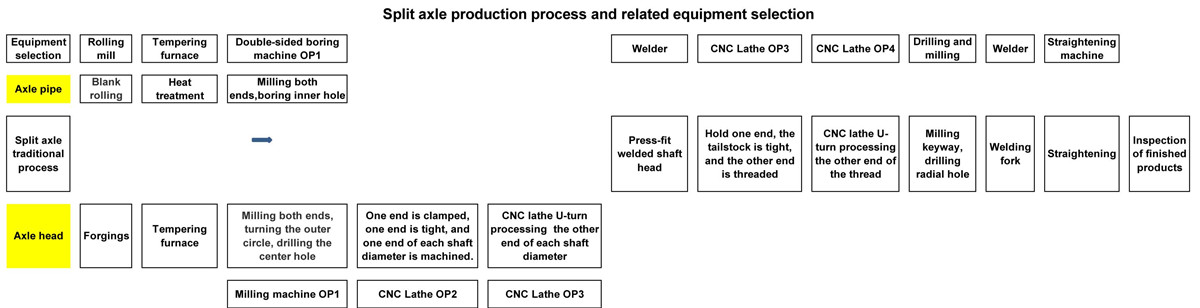

3.Split axle kugadzira maitiro:

Kubva pane iri pamusoro pekuita, iyo yekugadziridza midziyo yeaxle chubhu isati yaiswa welding inogona zvakare kusarudzwa seyakapetwa-yekupedzisira CNC lathe. Pakugadzirisa ekisero mushure mekugadzira, iyo yakakosha CNC lathe yekaviri-magumo axles inofanira kunge iri sarudzo yekutanga: panguva imwe chete kugadzirisa pamigumo yese, kukwirira kwekugadzirisa uye kunaka kwekugadzira machining. Kana iyo kiyi uye radial gomba kumigumo yese yeaxle ichida kugadzirwa, muchina uyu unogona zvakare kuve wakashongedzerwa nechibatiso chemagetsi kugadzirisa iyo inotevera kiyi uye radial gomba pamwechete.

4.Mukana uye chimiro chemushini mutsva wekusarudza maitiro:

1) Kuisa pfungwa kweiyo maitiro, kuderedza nguva dze workpiece clamping, kuderedza yekubatsira yekugadzirisa nguva, uchishandisa panguva imwe chete yekugadzira tekinoroji kumigumo yese, kugadzirwa kwakanaka kunovandudzwa zvakanyanya.

2) Imwe-nguva yekurovera, panguva imwe chete kugadzirisa pamigumo yese inovandudza machining iko uye coaxiality yeaxle.

3) Kupfupisa maitiro ekugadzira, kuderedza kutendeuka kwezvikamu panzvimbo yekugadzira, kunatsiridza kugona kwekushandiswa kwesaiti, uye kubatsira kuvandudza sangano uye manejimendi ekugadzira.

4) Nekuda kwekushandiswa kwemhando yepamusoro-yekugadzirisa michina, inogona kuve yakashongedzerwa nekurodha uye kurodha zvishandiso nemidziyo yekuchengetera kuti iwane zvizere kugadzira otomatiki uye kuderedza mutengo wevashandi.

5) Iyo workpiece inosungirirwa panzvimbo yepakati, iyo clamping yakavimbika, uye torque inodiwa pakucheka kwechishandiso chemuchina yakakwana, uye huwandu hukuru hwekutendeuka hunogona kuitwa.

6) Chishandiso chemuchina chinogona kuve chine otomatiki yekuona mudziyo, kunyanya kune gomo axle, iyo inogona kuve nechokwadi kukora kweyunifomu yeaxle mushure mekugadzira.

7) Kune maekisi maburi, kana maburi emukati kumagumo ese eOP1 sequencer apera, mutengi wechinyakare achashandisa imwe mugumo kusimudza simbi uye imwe magumo kushandisa tailstock kuomesa workpiece kutendeuka, asi saizi ye gomba remukati rakasiyana. Kune diki remukati gomba, kuomesa kusimba hakuna kukwana, torque yekusimbisa yepamusoro haina kukwana, uye kucheka kwakanaka hakugone kupedzwa..

Kune iyo nyowani-yechipiri-yechiso lathe, iyo gomba axle, kana maburi emukati kumagumo ese emota apera, muchina unochinja otomatiki nzira yekubatanidza: iyo miviri migumo inoshandiswa kuomesa workpiece, uye yepakati dhiraivha inoyangarara iyo workpiece. kutumira torque.

8) Iyo headstock ine yakavakirwa-mukati hydraulic clamping workpiece inogona kufambiswa munzira yeZ yemuchina. Mutengi anogona kubata chinzvimbo chepakati square chubhu (yakatenderera chubhu), nzvimbo yepasi ndiro uye shaft dhayamita yenzvimbo yeakisi sezvinodiwa.

5. Mhedziso:

Tichitarisa mamiriro ari pamusoro apa, kushandiswa kwekaviri-magumo CNC lathes kumashini emota maekisi ane mabhenefiti akakosha pane echinyakare maitiro. Iyo tekinoroji yepamberi yekugadzira iyo inogona kutsiva yechinyakare muchina maturusi maererano nemaitiro ekugadzira uye muchina chimiro.

Chikamu chepakati che

6.Axle mutengi nyaya

Special Double-end Axle CNC lathe Sumo

Axle processing range: ∮50-200mm, □50-150mm, kureba kwekugadzirisa: 1000-2800mm

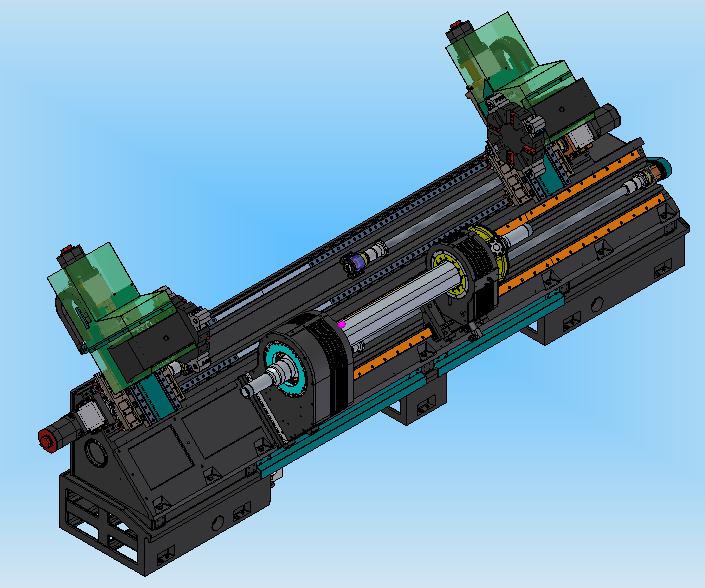

Chimiro chemuchina uye sumo yekuita

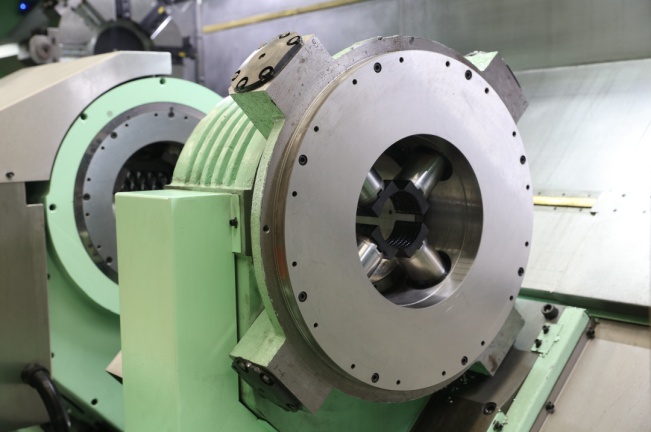

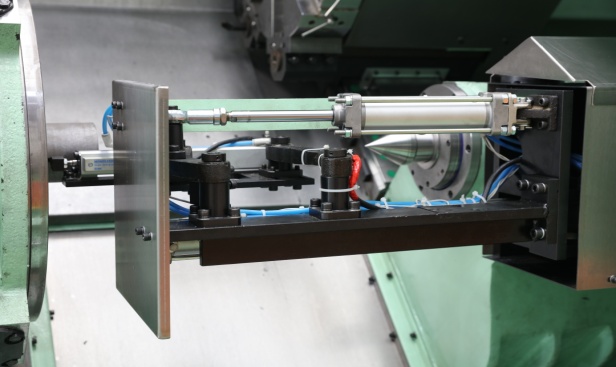

Chishandiso chemuchina chinotora 45 ° slant mubhedha dhizaini, ine yakanaka kusimba uye nyore chip evacuation. Iyo headstock ine yepakati drive clamping basa yakarongerwa pakati pemubhedha, uye maviri maturusi emidziyo akarongwa pamativi ese echipindo bhokisi. Iyo yakaderera clamping kureba kwemuchina ndeye 1200mm uye iyo yakanyanya machining kureba ndeye 2800mm. Iyo rolling guide inogamuchirwa, uye yega yega servo feed shaft inotora yakakwira-mute bhora screw, uye elastic coupling yakabatana zvakananga, uye ruzha rwakaderera, iko kurongeka uye kudzokororwa kwekumisikidza kwakakwira.

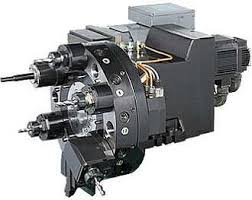

■ Muchina uyu wakashongedzerwa ne-two-channel control system. Iwo maviri anobata maturusi anogona kubatanidzwa kune chirungiso panguva imwe chete kana zvakasiyana kuti apedze panguva imwe chete kana sequential machining emativi maviri echikamu.

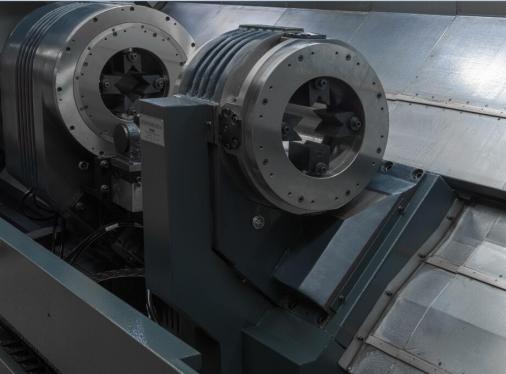

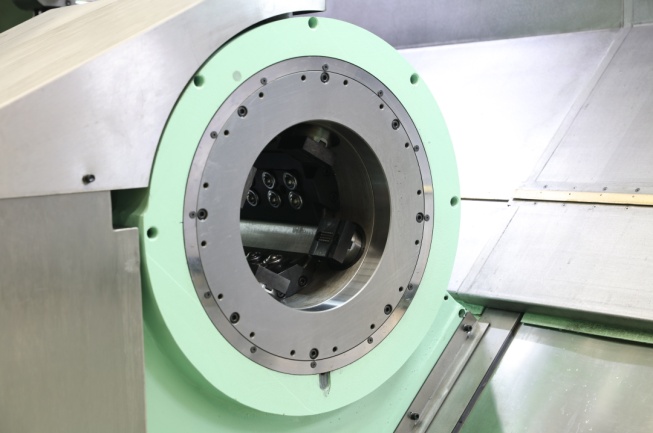

■ Muchina uyu wakashongedzerwa nekaviri misoro. Musoro mukuru unogadziriswa pakati pemubhedha, uye servo motokari inopa simba kune shaft huru kuburikidza nebhanhire rine mazino. Iyo sub-spindle bhokisi yakaiswa pane yakaderera gwara njanji yechishandiso chemuchina, coaxial ine main spindle bhokisi, uye inogona kufambiswa axially ne servo mota kuti ifambise kurodha uye kurodha kwezvikamu, uye zviri nyore kugadzirisa akasiyana clamping. zvinzvimbo. Paunenge uchigadzira zvikamu, iyo sub-spindle base yakavharwa kune muchina njanji. Iko coaxial kurongeka kweiyo misoro miviri inovimbiswa nemaitiro ekugadzira, zvichikonzera dhigirii yepamusoro yekumisikidzwa kwezvikamu zvakagadzirwa.

■ Iyo Headstock inobatanidza iyo spindle system, iyo inogadziriswa uye iyo oiri yekugovera sisitimu, uye ine compact chimiro uye yakavimbika kushanda. Iyo chaiyo clamping dhayamita uye hupamhi hwemusoro wemusoro unotemwa neaxle zvikamu zvemutengi.

Iyo huru headstock inodzikiswa nematanho maviri ebhandi uye giya, zvichiita kuti spindle ibudise torque hombe. Iyo clamp inoiswa kumucheto wekuruboshwe wemusoro mukuru uye kumucheto kwekurudyi kwe-sub-headstock zvichiteerana kuti uone kusungirirwa kwezvikamu. Kana musoro mukuru uchityaira zvikamu kuti zvitenderere, sub-headstock clamp clamping zvikamu zvinotenderera nemusoro mukuru.

Iyo gadziriso ine matatu radial silinda (mana radial silinda kana zvese zvakatenderedza zvinhu uye sikweya zvinhu zvakasungirirwa), piston inodzoserwa neiyo hydraulic pressure, uye makuhwa anoiswa kumagumo kwepiston kuti azvionere wega- pakati pezvikamu. Clamping. Inokurumidza uye iri nyore kushandura machira pakuchinja zvikamu. Iyo clamping simba inogadziriswa neiyo hydraulic system hydraulic pressure. Kana chikamu chacho chikagadzirwa, iyo clamp inotenderera neshaft huru, uye iyo mafuta ekugovera sisitimu inopa mafuta kune iyo clamp, kuitira kuti iyo clamp ive yakakwana clamping simba panguva yekutenderera. Iyo clamp ine mabhenefiti ehombe clamping force uye hombe claw sitiroko.

■ Kuti ugadzirise dambudziko reunifomu yemadziro ukobvu mushure memutengi mhango axle machining, muchina unogona kuve wakashongedzerwa otomatiki workpiece yekuongorora mudziyo. Mushure mekunge axle clamping yapera, workpiece inoona otomatiki kuti probe inowedzera uye inoyera chinzvimbo chebasa; mushure mekunge kuyerwa kwapera, mudziyo unodzokera munzvimbo yakavharwa.

Kune akasiyana machining maitiro emaakisi asina magomba, kana iyo inotakura chinzvimbo ichishandiswa seyekudzvanya referensi, iyo muchina dhizaini ine otomatiki clamping uye clamping inogona kusarudzwa, uye programmable tailstock inopihwa mativi ese eiyo huru uye yekubatsira spindle misoro kusangana ne zvinodiwa zvemuchina mumwe. Zvinotarisirwa kupedzisa kugadzirisa matanho maviri panguva. Panguva imwecheteyo, inoitawo kuti zvikamu zveotomatiki kurodha uye kurodha zvive nesarudzo uye zvirinani.

■ Zvibatiso zvekuruboshwe nekurudyi zvinogona kugadzikwa nezvibatiso zvematurusi zvakajairika kana maturusi emagetsi. Vane mabasa ekuchera nekugaya, ayo anogona kupedzisa kuchera uye kugaya kwezvikamu zvakakosha.

■Chishandiso chemuchina chakavharirwa zvizere uye chine otomatiki yekuzora mudziyo uye otomatiki chip yekubvisa mudziyo (kumberi). Iyo ine yakanaka kuchengetedza kuita, kutaridzika kwakanaka, kushanda kuri nyore uye kugadzirisa kuri nyore.

■ Iyo yeruzivo rwemuchina uye zvigadziriso zvinotemerwa zvinoenderana neaxle zvinodiwa uye zvinodiwa nevatengi, uye hazvidzokororwe pano.

Ndatenda nekutarisisa kwako!