BOSM -6010 Inopikisa-Musoro Boring Milling Machine

1. Kushandisa muchina:

BOSM- 6000 * 1000 fixed-beam CNC gantry kaviri-column musoro-kune-musoro unofinha uye muchina wekugaya chinhu chakakosha muchina chekugadzirisa maoko / zvimiti zvekuchera. Pillow, inogona kuona kukurumidza kugadzirisa kweiyo workpiece, iyo workpiece inogona kudhonzwa, kunyungudutswa, uye kufinhwa mukati meiyo inoshanda sitiroko renji, iyo workpiece inogona kugadziriswa panzvimbo panguva imwe chete (hapana kudiwa kwechipiri clamping), kurodha uye kurodha kumhanya. inokurumidza, iyo yekumisikidza kumhanya inokurumidza, uye iko kurongeka kwakakwira. Yakakwirira, yakakwirira yekugadzirisa kushanda zvakanaka.

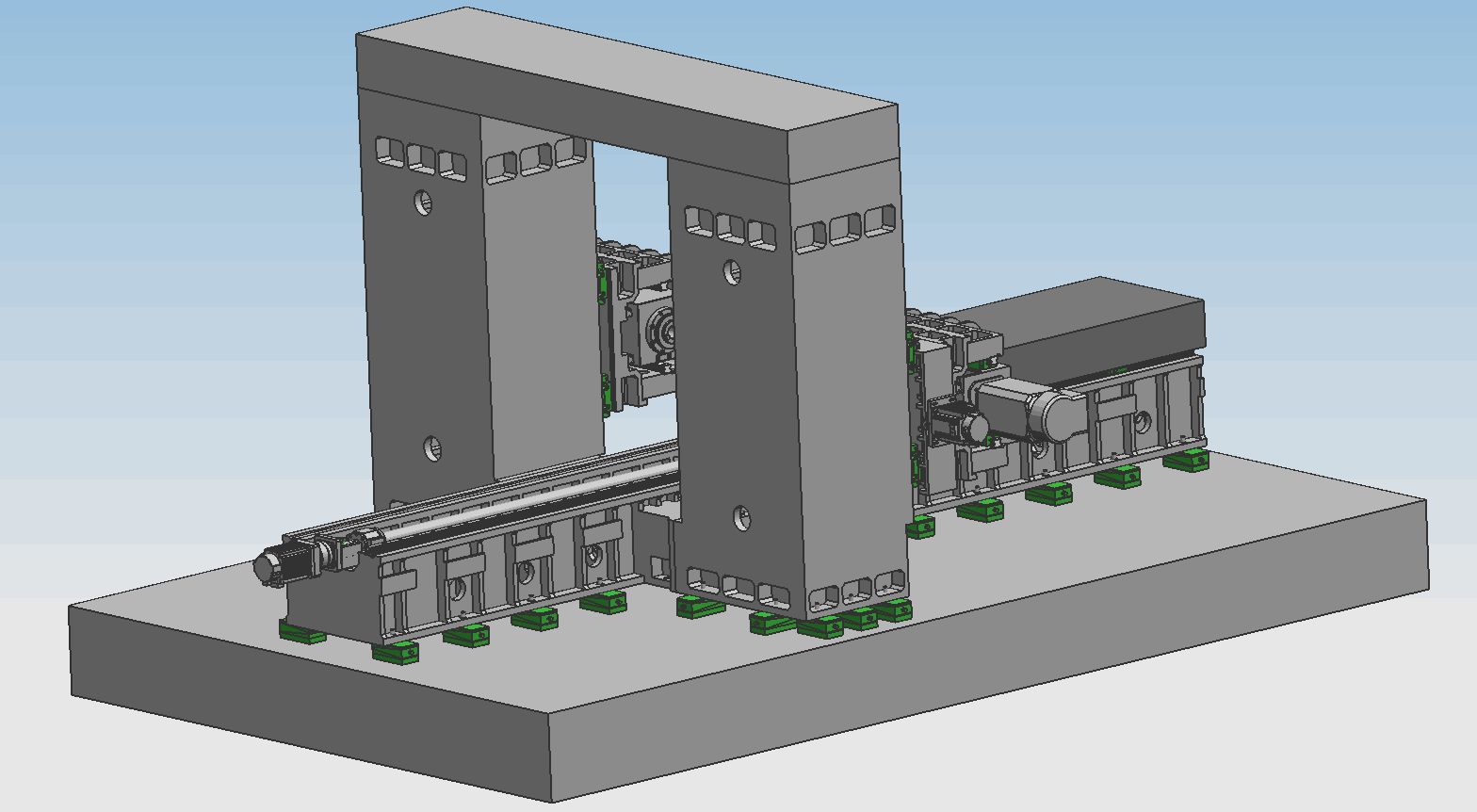

2.Chimiro chemuchinafeatures:

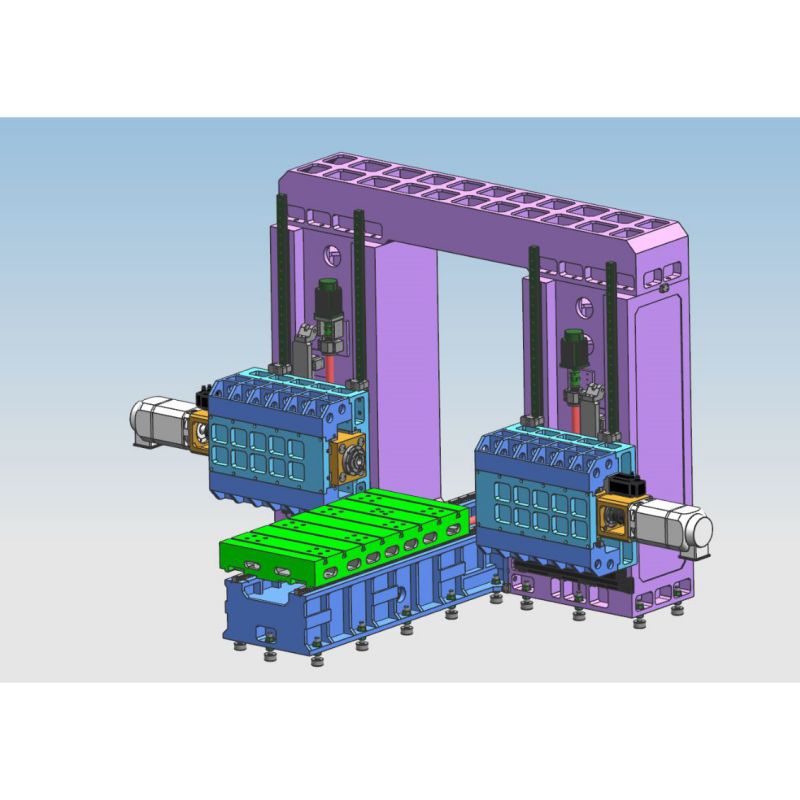

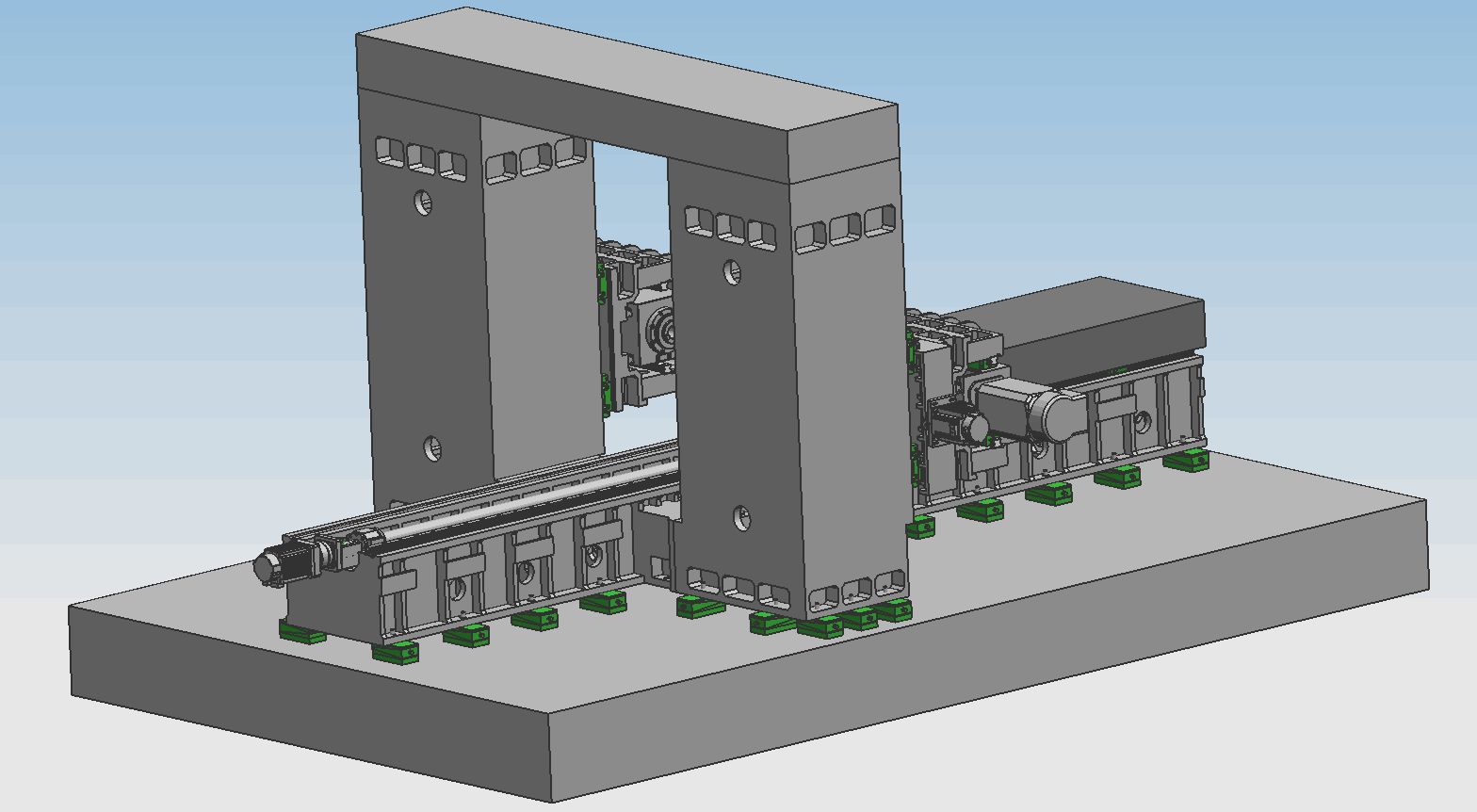

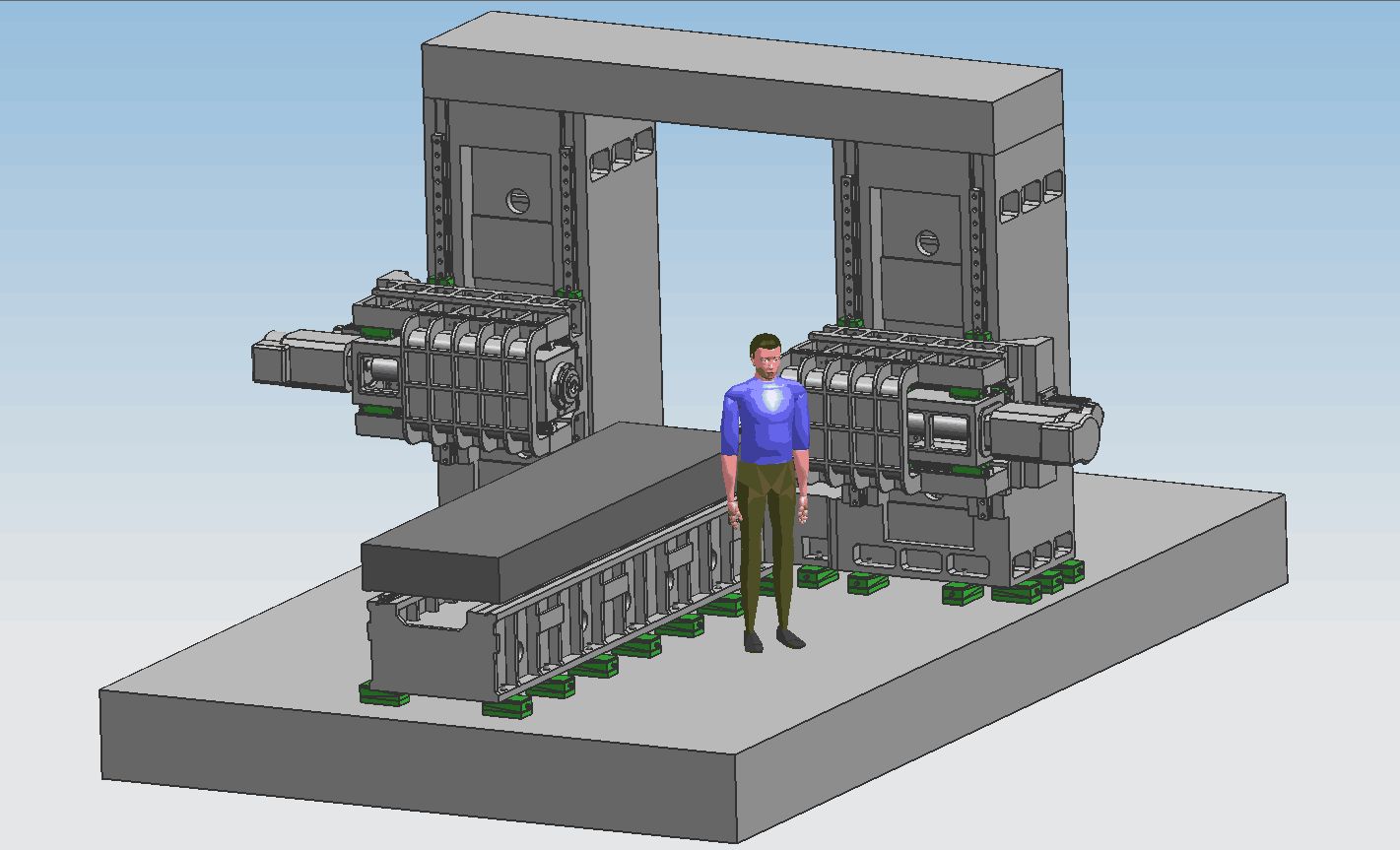

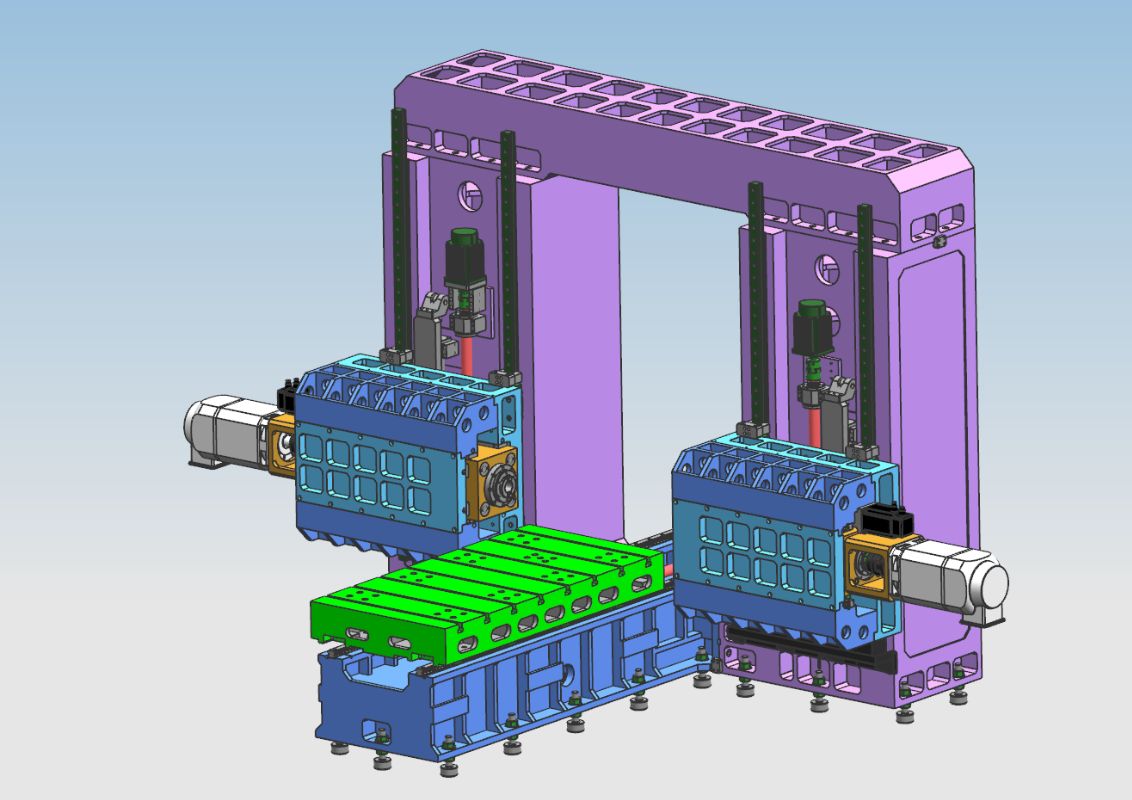

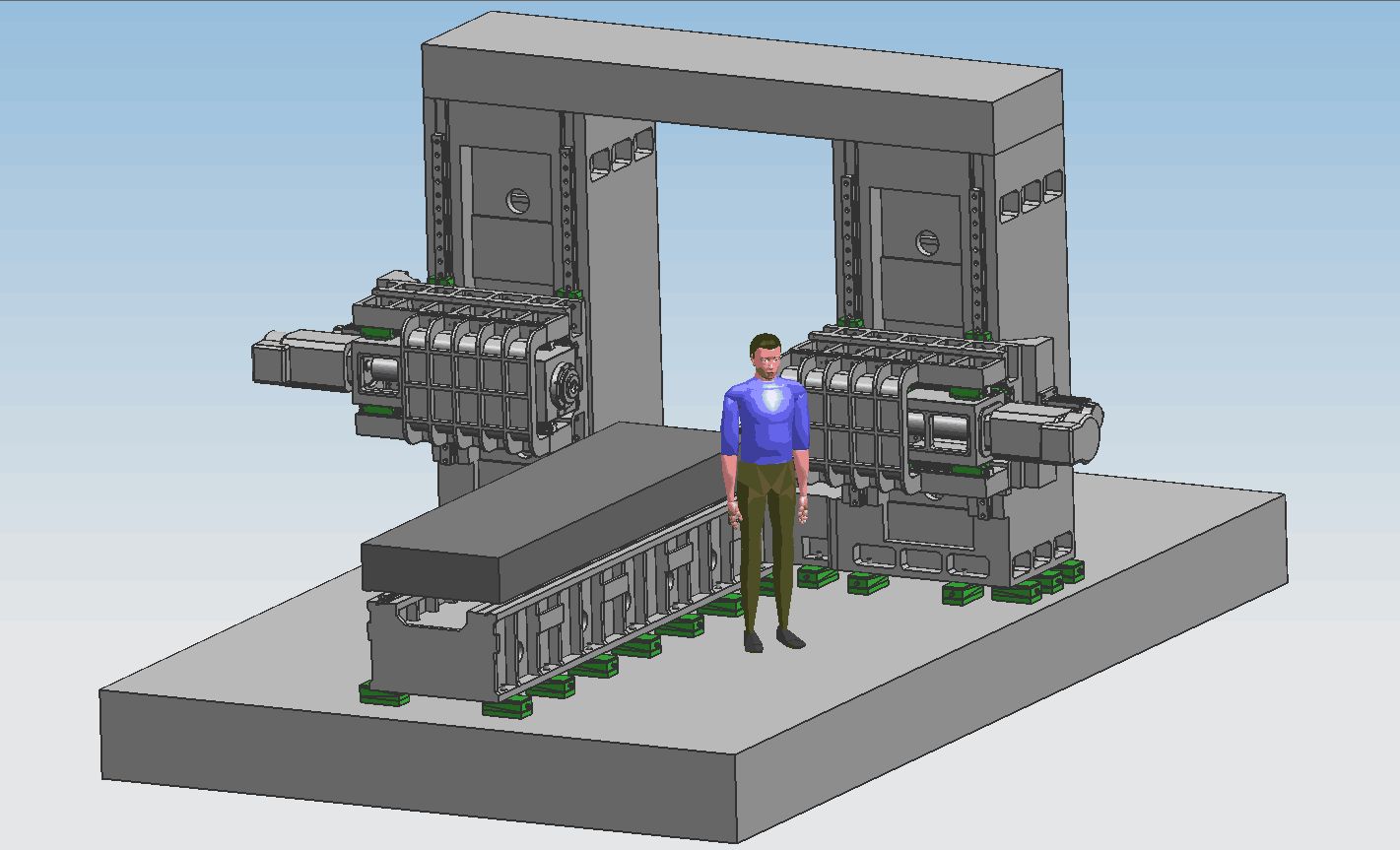

Izvo zvakakosha zvechishandiso chemuchina: mubhedha, bhenji rekushanda, kuruboshwe uye kurudyi makoramu, matanda, gantry anobatanidza matanda, zvigaro, makondohwe, nezvimwe, zvikamu zvakakura zvinogadzirwa neresin jecha kuumbwa, yepamusoro-mhando grey iron 250 kukanda, yakanyudzwa mukupisa. gomba rejecha → kuchembera kuchembera → kurapwa kupisa Kupisa → kuzunguzika kuchembera → kugadzirwa kwakakasharara → kudedera kuchembera → kupisa kwevira → kukwenya kuchembera → kupedza, kubvisa zvachose kusagadzikana kwakashata kwezvikamu, uye chengetedza kuita kwezvikamu zvakadzikama. Iyo yakagadziriswa mubhedha, kuruboshwe uye kurudyi makoramu, gantry, uye bhenji rekushanda; Iine mabasa ekugaya, kufinha, kuchera, kudonhedza pasi, kubaya, nezvimwewo. Nzira yekutonhodza yemidziyo ndeyekunze kutonhora. Chishandiso chemuchina chine 5-axis yekubatanidza, iyo inogona kuona 4-axis yekubatanidza uye 5-axis imwe-chiito. Kune misoro miviri yemagetsi. Iyo axis yemuchina mudziyo uye musoro wesimba unoratidzwa mumufananidzo uri pazasi.

2.1Chimiro chikuru cheaxial transmission feed chikamu

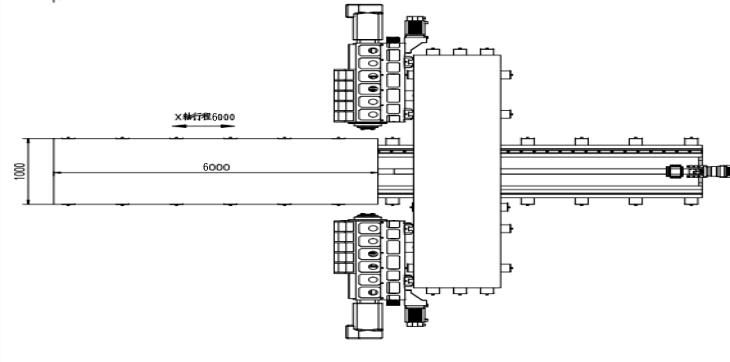

2.1.1. X-axis:Iyo worktable inodzokororwa nechemberi pamwe chete negwara renjanji yemubhedha wakagadzika.

X 1- axis drive: AC servo mota pamwe nepamusoro-chaiyo puraneti inoderedza inofambiswa nebhora screw kutyaira kufamba kwebhenji rekushanda kuti uone mutsara wekufamba kweX-axis.

Gwaro renjanji fomu: isa mbiri-yakasimba-yakasimba mitsara inotungamira njanji.

2.1.2 Z1 axis:Musoro wesimba nechigaro chechigaro zvakamiswa padivi pembiru yekoramu, uye dzorera kumusoro nekudzika pamwe negwara renzira.

Z1-axis kutapurirana: AC servo mota uye synchronous vhiri rinoshandiswa kutyaira bhora sikuru kutyaira chigaro kuti uone Z- axis mutsara kufamba.

2.1.3 Z2 axis:Musoro wesimba nechigaro chechigaro zvakamiswa padivi pembiru yekoramu, uye dzorera kumusoro nekudzika pamwe negwara renzira.

Z2-axis kutapurirana: AC servo mota uye synchronous vhiri rinoshandiswa kutyaira bhora sikuruu kutyaira chigaro kuti uone Z- axis mutsara kufamba.

2.1.4 Y1 axis:Musoro wechigaro chesimba unoiswa wakatwasuka parutivi rwemberi kwekoramu yekurudyi, uye inodzorera kuruboshwe nekurudyi pamwe chete nekoramu yegwara renjanji.

Y1-axis kutapurirana: AC servo mota pamwe nepamusoro-chaiyo planetary reducer inoshandiswa kutyaira gondohwe kuti rifambe nepakati pebhora screw kuti rione mutsara wekufamba kweY1- axis.

2.1.5 Y2 axis:Chigaro chemusoro chesimba chakamiswa pamberi pembiru yekurudyi, uye chinodzoreredza kuruboshwe nekurudyi pamwe chete negwara renjanji.

Y2-axis kutapurirana: AC servo mota pamwe nepamusoro-chaiyo puraneti inoderedza inoshandiswa kutyaira gondohwe kuti rifambe nepakati pebhora screw kuti rione Y2- axis linear kufamba.

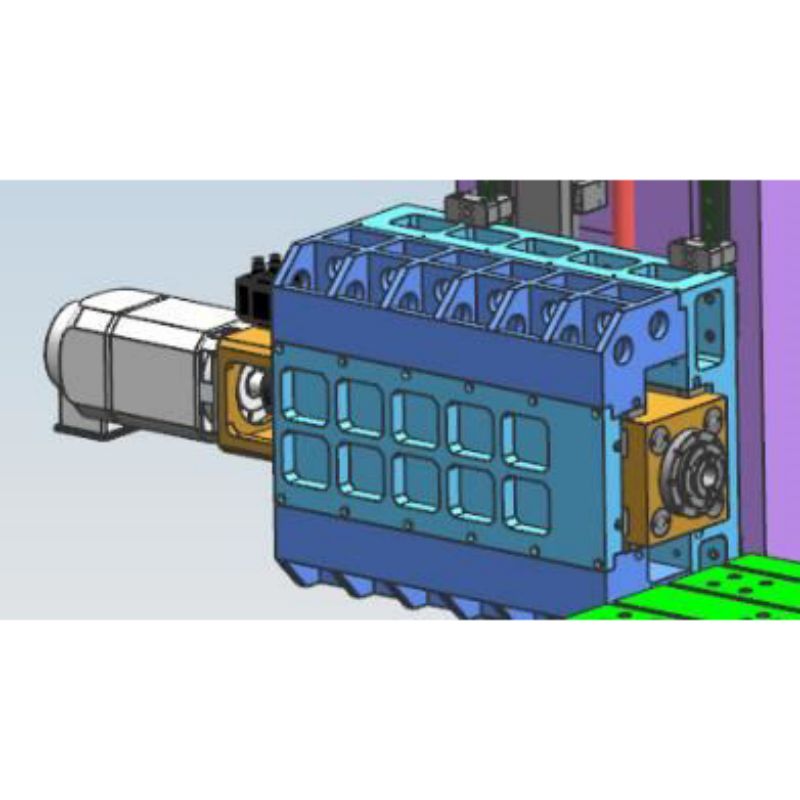

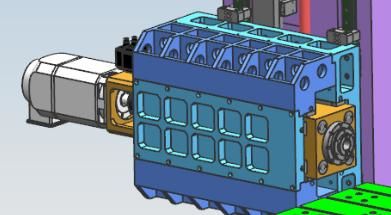

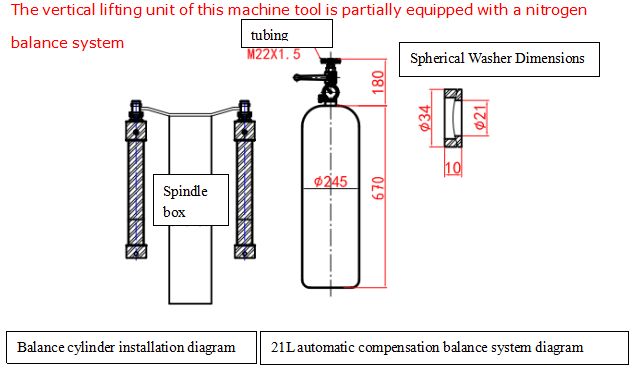

2.2 Nzira inofamba yekuchera uye kugaya simba remusoro (kusanganisira musoro wesimba 1 uye 2) inotungamirirwa ne 4 linear roller guide rail pairs, uye dhiraivha inotora AC servo mota kutyaira bhandi rinoenderana (i = 2) uye bhora chairo. screw pair transmission. Musoro wesimba unotora servo Iyo mota inodzikiswa nebhandi rinoenderana uye vhiri rinoenderana, rinotungamirwa neanorema-duty precision gwara renjanji, uye inotyaira yakamira bhora screw kuti itenderere kuona kufamba kwakamira kwemusoro wesimba. Iyo zvakare yakashongedzerwa neiyo nitrogen balance bar kudzikisa musoro-ku-screw uye servo mota. Iyo Z-axis mota ine otomatiki brake basa. Muchiitiko chekutadza kwemagetsi, iyo otomatiki brake inobata shaft yemota zvakasimba kuti isatenderere. Paunenge uchishanda, kana iyo drill bit isingabate workpiece, ichadya nekukurumidza; kana chibooreso chikabata workpiece, chinozochinja otomatiki kuenda kunoshanda feed. Kana iyo drill bit inopinda mukati meiyo workpiece, inozochinja otomatiki kutsanya rewind; kana kupera kwechibooreso kuchisiya workpiece uye kunosvika panzvimbo yakatarwa, iyo worktable inoenda kune inotevera gomba chinzvimbo kuti uone otomatiki kutenderera. Musoro wesimba unotora kusanganiswa kwewaya uye njanji yakaoma, iyo isingangoiti kuti iite kumhanya kwemidziyo, asi zvakare inowedzera zvakanyanya kuomarara kwemidziyo. Uye inogona kuona mabasa ekuboora gomba remapofu, kugaya, chamfering, chip breaking, otomatiki chip kubviswa, nezvimwewo, izvo zvinovandudza basa revashandi.

(musoro wekuruboshwe wesimba)

2.3. Kubvisa chip uye kutonhora

Kune spiral uye flat chain chip conveyors akaiswa pamativi ese pazasi pebhenji rebasa, uye machipisi anogona kuburitswa otomatiki kune chip conveyor kumagumo kuburikidza nematanho maviri ekutenderera uye cheni mahwendefa kuti uone kugadzirwa kwakabudirira. Pane pombi inotonhodza mutangi inotonhorera yechip conveyor, inogona kushandiswa kutonhorera kwekunze kwechishandiso kuti ive nechokwadi chekushanda kwekuchera uye hupenyu hwesevhisi hwechibhorani, uye chinotonhodza chinogona kudzokororwa.

3. Yakazara yedhijitari nhamba yekudzora system:

3.1. Ne chip breaking function, chip breaking time uye chip breaking cycle inogona kuiswa pane man-machine interface.

3.2. Iine chishandiso chekusimudza basa, chishandiso chekusimudza kureba chinogona kusetwa pane murume-muchina interface. Kana kuchera kunosvika pakureba uku, chibooreso chinokurumidza kusimudzwa kumusoro kwechishandiso, uye ipapo machipisi anokandwa kure, obva akurumidza kuendeswa kunzvimbo yekuchera uye otomatiki anoshandurwa kushanda.

3.3. Centralized operation control box uye handheld unit inotora nhamba yekudzora system uye ine USB interface uye LCD liquid crystal display. Kuti ufambise hurongwa, kuchengetedza, kuratidza uye kutaurirana, iyo interface yekushandisa ine mabasa akadai semurume-muchina dialogue, muripo wekukanganisa, uye otomatiki alarm.

3.4. Iyo midziyo ine basa rekutarisa uye kuongorora zvakare nzvimbo yegomba isati yagadziriswa, uye kushanda kwacho kuri nyore.

3.5. Automatic lubrication

Muchina wekushandisa chaiwo mutsara wegwara njanji pairi, chaiyo bhora screw pairs uye mamwe akanyanya-chaiyo mafambiro pairi ane otomatiki lubrication masisitimu. Iyo otomatiki yekuzora pombi inoburitsa kumanikidza mafuta, uye iyo yehuwandu yekuzora mafuta kamuri inopinda muoiri. Mushure mokunge kamuri yemafuta yakazadzwa nemafuta, apo hurongwa hwekumanikidza hunokwira kusvika ku 1.4-1.75Mpa, shanduko yemagetsi muhurongwa yakavharwa, pombi inomira, uye kuvhara kwevhavha inosunungura panguva imwe chete. Kana kudzvinyirirwa kwemafuta mumugwagwa kunodonha pazasi 0.2Mpa, iyo yekuwedzera lubricator inotanga kuzadza nzvimbo yekuzora uye inopedzisa kuzadza mafuta. Nekuda kweiyo chaiyo yekupihwa kwemafuta eiyo yakawanda mafuta injector uye nekuonekwa kweiyo system kudzvanywa, mafuta anopihwa anovimbika, kuve nechokwadi chekuti pane firimu remafuta pamusoro pega yega kinematic pair, kuderedza kukweshera nekupfeka, uye kudzivirira kukuvadzwa. chimiro chemukati chinokonzerwa nekupisa. , kuve nechokwadi chechokwadi uye hupenyu hwemuchina chishandiso. Kuenzaniswa neinotsvedza njanji njanji, iyo inotenderera mutsara njanji peya inoshandiswa muchina ichi chishandiso ine zvakatevedzana zvakanakira:

①Iyo yekufamba senitivity yakakwira, friction coefficient ye rolling guide njanji idiki, chete 0.0025 ~ 0.01, uye simba rekutyaira rakadzikiswa zvakanyanya, iro rinongofanana ne1/10 yemuchina wakajairwa.

② Musiyano uripo pakati pesimba uye static friction idiki kwazvo, uye yekutevera kuita kwakanakisa, ndiko kuti, nguva yekufamba pakati pechiratidzo chekutyaira uye chiitiko chemuchina ipfupi zvakanyanya, izvo zvinobatsira mukuvandudza kukurumidza kwekupindura uye kunzwa kwe iyo nhamba yekudzora hurongwa.

③Iyo inokodzera kukwirisa-kumhanya kwemutsara, uye kumhanya kwayo kwepakarepo kunokwira kanokwana kagumi pane iya yekutsvedza njanji.

④ Inogona kuona kufamba kusina gap uye kugadzirisa kuoma kwekufamba kweiyo mechanika system.

⑤Inogadzirwa nevagadziri vane hunyanzvi, ine chaiyo chaiyo, yakanaka kuita zvakasiyana-siyana uye nyore kugadzirisa.

4. Mashandisirwo emuchina nharaunda:

Simba rekushandisa: matatu-chikamu AC380V ± 10%, 50Hz ± 1 Ambient tembiricha: 0 ° ~ 45 °

5. Maintechnical parameters:

| Model | BOSM6010 | |

| Maximum processing workpiece saizi | Kureba × upamhi × kureba (mm) | 6000×1000×1500 |

| Gantry maximum feed | Upamhi (mm) | 1300 |

| kushanda dhesiki saizi | Kureba X Kufara (mm) | 6000*1000 |

|

Horizontal gondohwe mhando yekuchera musoro simba musoro mumwe maviri

| Huwandu (2) | 2 |

| Spindle taper | BT50 | |

| Kuchera dhayamita (mm) | Φ2-Φ60 | |

| Kubata dhayamita (mm) | M3-M30 | |

| Spindle kumhanya (r/min) | 30-6000 | |

| Servo spindle mota simba (kw) | 37 | |

| Single spindle mhuno chinhambwe kubva patafura centre (mm) | 150-650 | |

| Nzvimbo yepakati yekaviri spindle mhino yekupedzisira (mm) | 300-1300 | |

| Kuruboshwe nekurudyi kwegondohwe rimwe chete (mm) | 500 | |

| Nhambwe iri pakati pepakati pegondohwe nendege yetafura (mm) | 200-1700 | |

| Kukwira nekudzika kwegondohwe (mm) | 1500 | |

| Kudzokorora | 300mm*300mm | ±0.02 |

| Machine Tool Dimensions | Kureba × upamhi × kureba (mm) | maererano nemifananidzo |

| Huremu huremu (t) | (inenge.) 36 | |

Iwo ari pamusoro apa parameters ekutanga dhizaini paramita. Muchigadzirwa chaicho, panogona kunge paine shanduko zvinoenderana nezvinodiwa zvekugadzirisa zvechishandiso uye zvinodiwa zvekugadzira zvemuchina chishandiso, kuitira kuti usangane nezvinodiwa zvemakambani ako ekugadzirisa zvikamu.