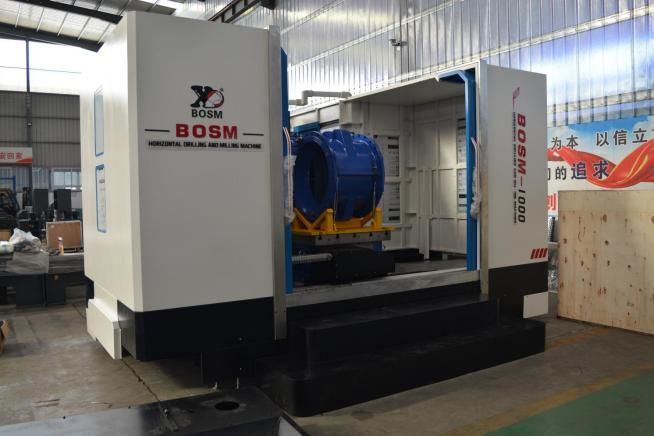

BOSM -4Z2000 Yakakwira kumhanya CNC kuchera uye muchina wekugaya

1.Equipment kushandiswa:

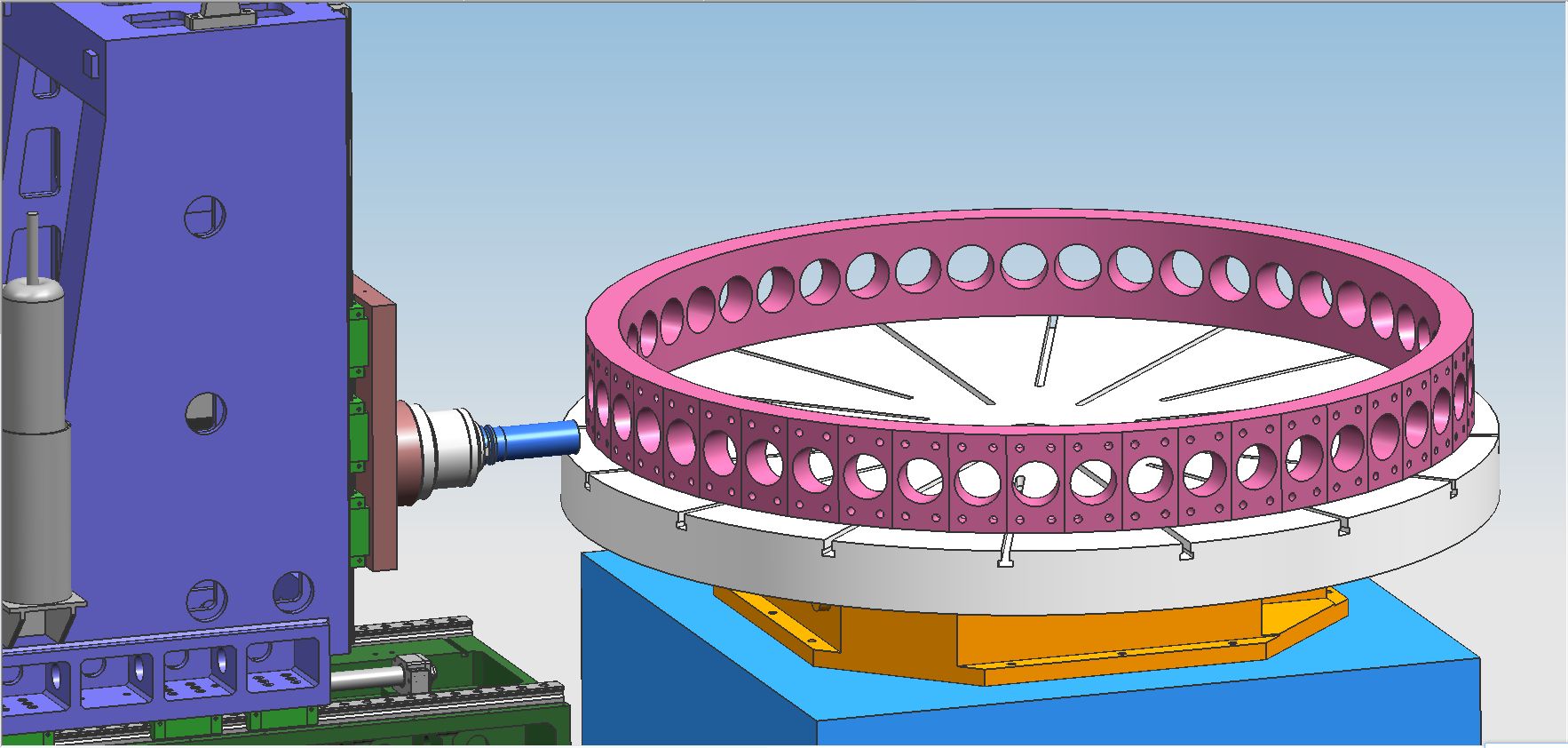

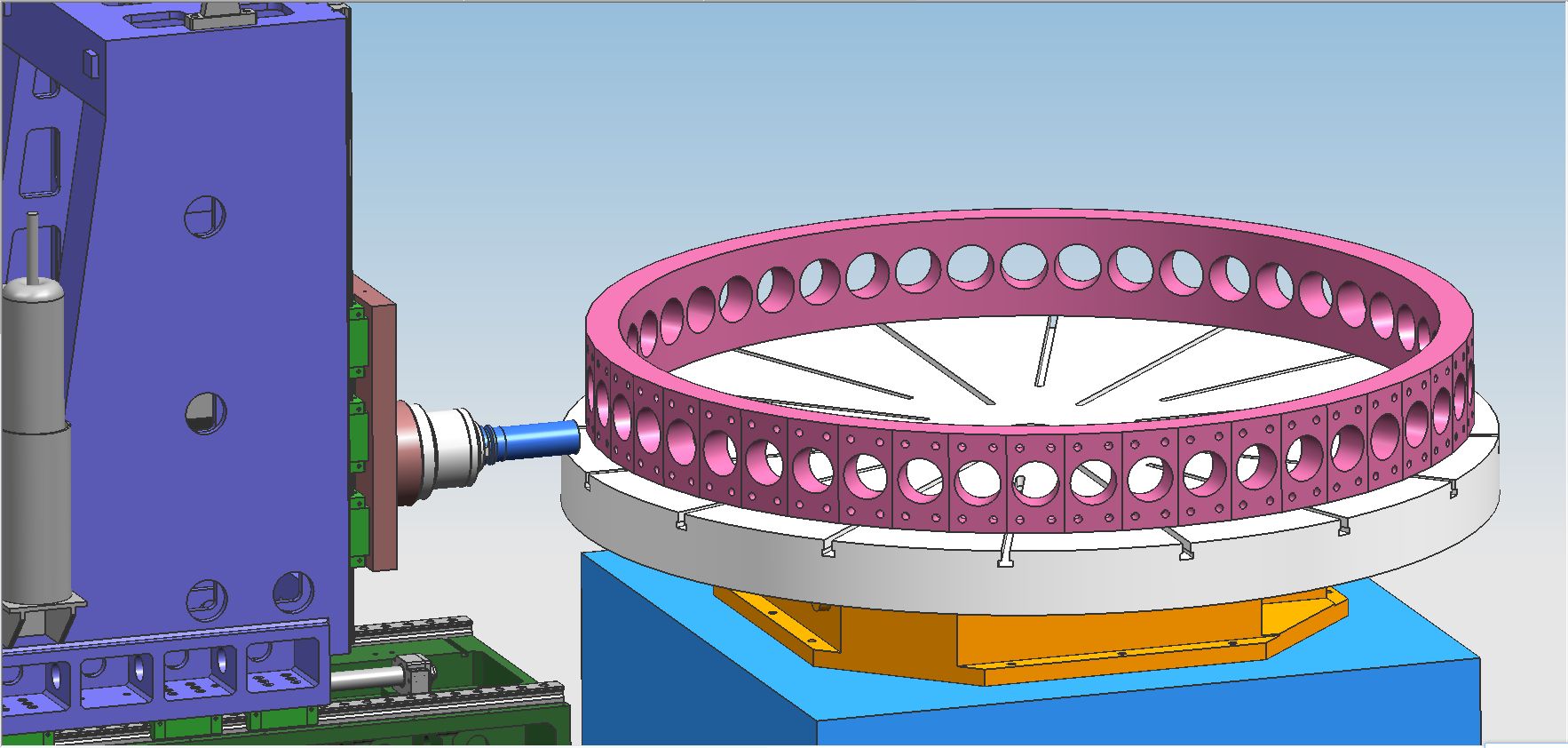

BOSM-1000 horizontal CNC yekuchera uye muchina wekugaya unonyanya kushandiswa kune akawanda-faceted anobudirira kuchera, kugaya, kubaya uye kufinha kugadzirwa kwemavharuvhu, mavharuvhu block, zvinoderedza, flanges, discs, zvindori, zvitsigiro zvekuuraya uye mamwe maworkpiece mukati meiyo inoshanda yehukobvu. . Kudhiraivha, kugaya, kubaya uye kufinha kunogona kuwanikwa pazvikamu zvezvinhu zvimwechete uye zvinhu zvinoumbwa. Iyo machining maitiro eMuchina inodzorwa nedhijitari, uye mashandiro acho ari nyore kwazvo. Inogona kuona otomatiki, yakanyanya kurongeka, yakawanda-siyana uye kugadzirwa kwakawanda.

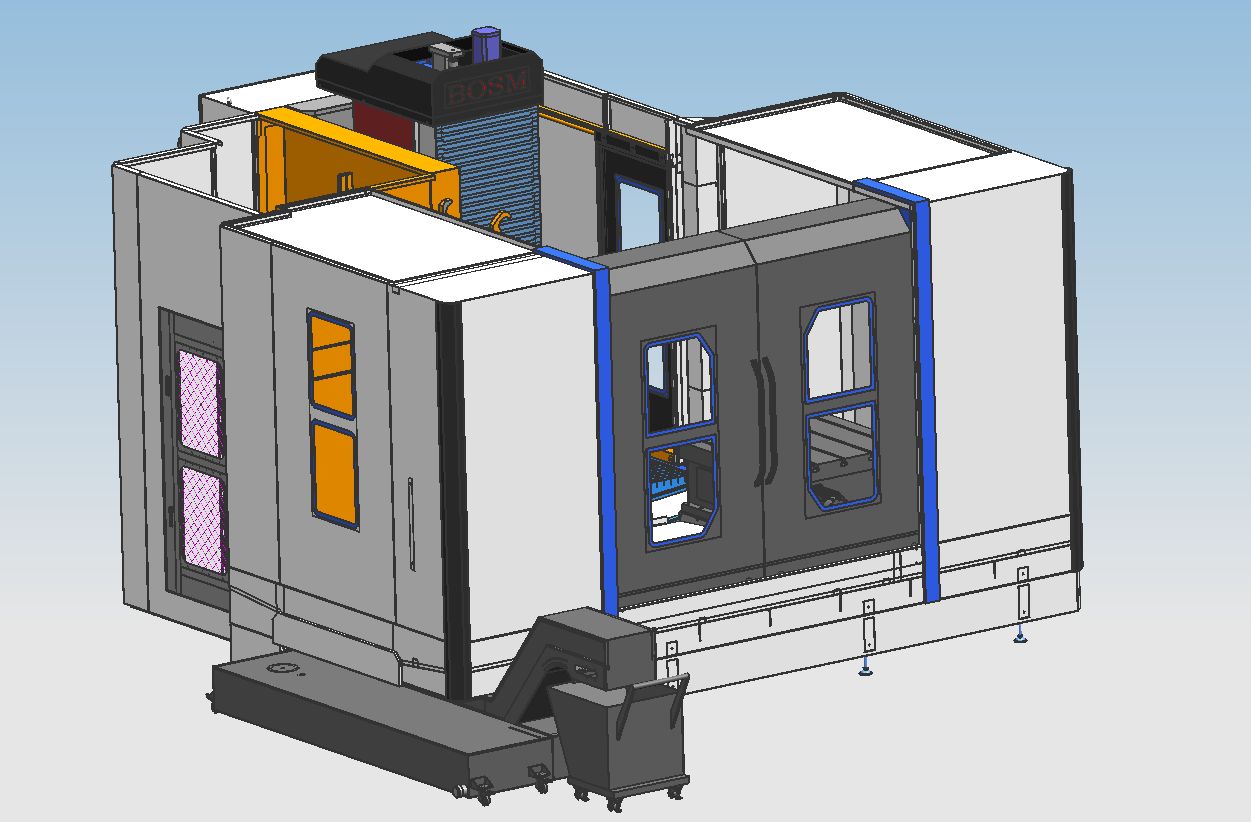

2. Equipment chimiro:

Midziyo iyi inonyanya kuumbwa nemubhedha, CNC indexing rotary tafura, mbiru inofambiswa, chigaro chinotakurika, kuchera uye kugaya simba musoro, otomatiki lubrication mudziyo uye mudziyo wekudzivirira, inotenderera inotonhorera mudziyo, dhijitari control system, hydraulic system, magetsi system uye zvichingodaro. Iyo rolling linear njanji inotsigirwa uye inotungamirwa, uye iyo chaiyo screw inotyairwa. Iyo Machine ine yakakwirira chinzvimbo kurongeka uye inodzokorora kurongeka kwenzvimbo.

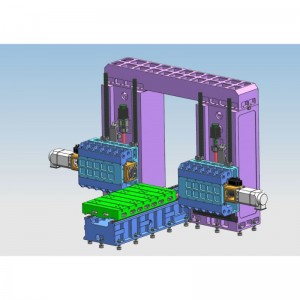

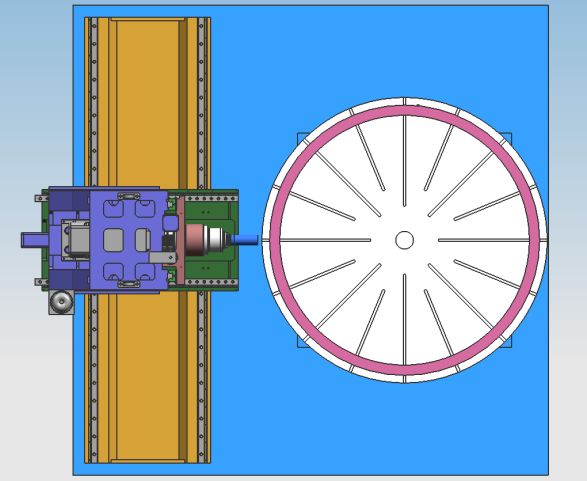

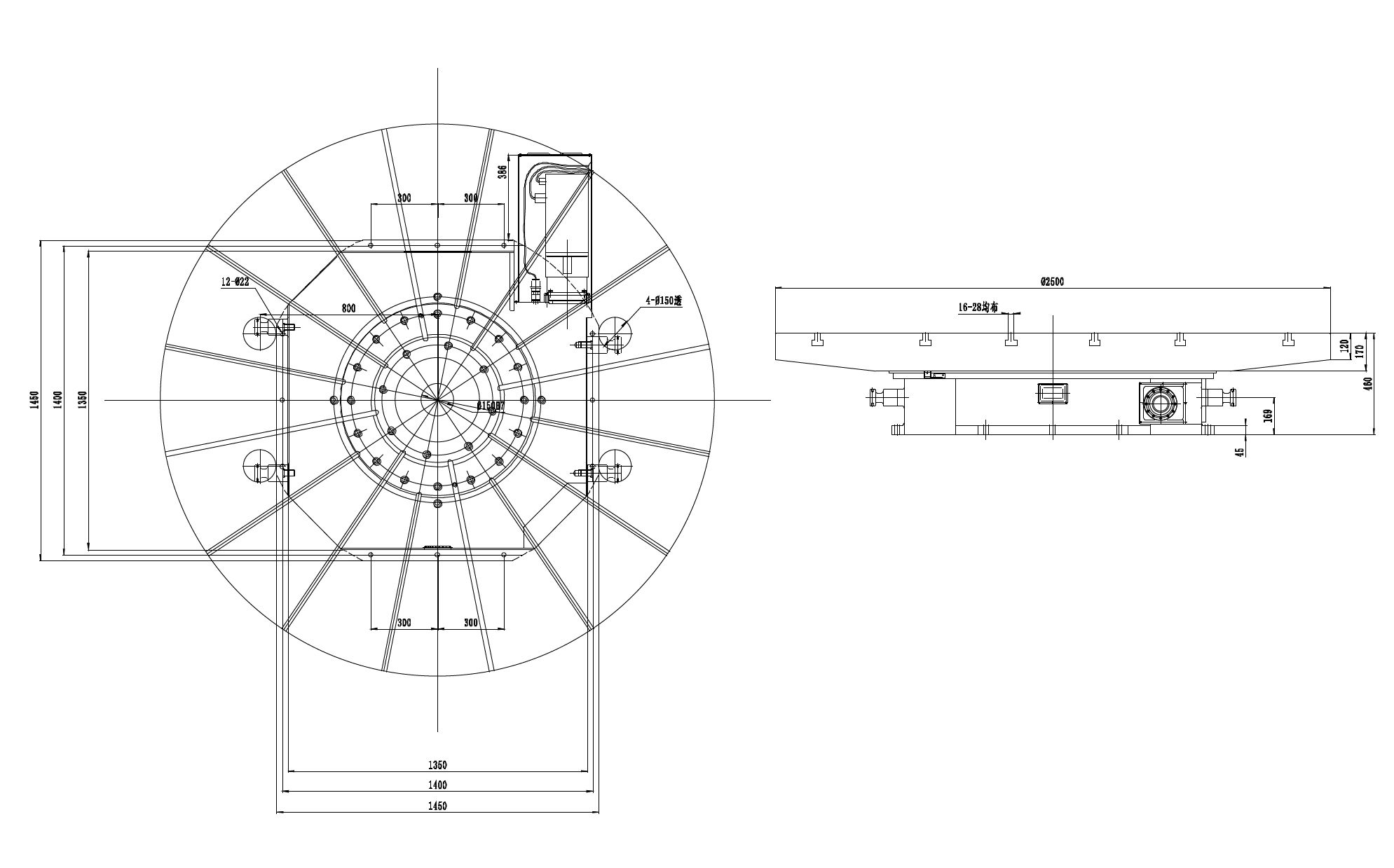

2.1. Bed worktable: Mubhedha wakagadzirwa neHT250 cast iron structural parts. Inopedzwa mushure mekupisa kwechipiri kubvisa kushushikana kwemukati. Iyo ine yakanaka dynamic uye static rigidity uye haina deformation. Precision nhamba yekudzora indexing plate, servo drive 360 ° inopokana indexing chinzvimbo uye mhepo / hydraulic kukiya, dhiraivha system inoshandisa AC servo mota kuti iratidze otomatiki shaft inotenderera chikamu 360 °, uye iko kurongeka kwechiuru chimwe chedhigirii. Iyo indexing plate inoiswa pamusoro pemubhedha, uye mabhaudhi anogadziriswa anogoverwa pasi pemubhedha, izvo zvinogona kugadzirisa nyore mwero wemubhedha worktable.

2.2. Koramu inofambiswa: Iyo inofambiswa yakakandwa simbi chimiro mbiru inopedzwa mushure mechipiri kupisa kurapwa kubvisa kushushikana kwemukati. Iyo ine yakanaka dynamic uye static rigidity uye haina deformation. Seti yechaiyo bhora screw pair uye servo mota inoita kuti column inotsvedza ifambe munzira yeY-axis. Seti yechaiyo bhora screw pair uye servo mota inoita kuti column inotsvedza ifambe munzira yeX-axis. Isa chibhorani chekuchera pane iyo unit slide. Kufamba kwekoramu kunoonekwa nekutenderera kwebhora nati pane bhora screw inofambiswa ne servo mota kuburikidza nekubatanidza.

2.3. Nharembozha saddle: Iyo nhare yechigaro ine maviri ekupedzisira-yakakwirira kutakura kugona kutenderedza linear njanji peya, seti yechaiyo bhora screw pair uye servo mota, inotyaira iyo yekudhirowa musoro wesimba kufamba munzira yeZ-axis, inogona. ziva Simba musoro nekukurumidza kumberi, shanda kumberi, kukurumidza kudzoka, mira uye zvimwe zviito. Iyo ine mabasa e otomatiki chip breaking, chip kubvisa uye kumbomira.

2.4. Musoro wesimba rekuchera: Musoro wesimba rekuchera unotora Taiwan mechini spindle, uye chaiyo chaiyo spindle inotora angular yekubata inotakura, iyo inoona isina nhanho yekumhanya shanduko kuburikidza nepamusoro-simba synchronous bhandi kutapurirana. Inotyairwa nema servo motors uye bhora screws. Iyo Y-axis inogona kubatanidzwa, inotora semi-yakavharwa-loop control, uye inogona kuona mutsara uye denderedzwa kududzira mabasa. Iyo spindle end iBT50 taper gomba.

2.5. Otomatiki lubrication mudziyo uye kudzivirira mudziyo:

Muchina uyu wakashongedzerwa neotomatiki lubrication mudziyo, unogona kungoisa mafuta pairi inofamba senge njanji, lead screws, uye racks. Machine

Iyo Z-axis uye Y-axis yakashongedzerwa neguruva-proof yekudzivirira mavhavha, uye isina mvura inoputika baffles akaisirwa akatenderedza worktable.

2.6. Yakazara yedhijitari nhamba yekudzora system:

2.6.1. Ne chip breaking function, chip breaking time uye chip breaking cycle inogona kuiswa pane man-machine interface.

2.6.2. Yakashongedzerwa nechishandiso chekusimudza basa, chishandiso chekusimudza kureba chinogona kusetwa pane murume-muchina interface. Kana kuchera kunosvika pakureba uku, chibooreso chinokurumidza kusimudzwa kumusoro kwechishandiso, ipapo machipisi anokandwa kure, obva akurumidza kuendeswa kunzvimbo yekuchera uye otomatiki anoshandurwa kushanda.

2.6.3. Centralized operation control box uye hand-hold unit inotora nhamba yekudzora system uye ine USB interface uye LCD liquid crystal display screen. Kuti ufambise hurongwa, kuchengetedza, kuratidza uye kutaurirana, iyo interface yekushandisa ine mabasa akadai semurume-muchina dialogue, muripo wekukanganisa, uye otomatiki alarm.

2.6.4. Iyo midziyo ine basa rekutarisa uye kuongorora zvakare nzvimbo yegomba isati yagadziriswa, uye mashandiro acho ari nyore kwazvo.

* Kuti uve nechokwadi chekureruka kwekusimudza nekudyisa zvindori zvakakura, Muchina hauna dziviriro yekunze, uye kudzivirira kwekunze kunosarudzika.

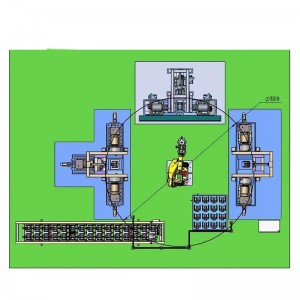

3. Machineshandisa nharaunda:

Magetsi: Matatu-chikamu AC380V±10%, 50Hz±1 Ambient tembiricha: 0°~ 45°

4.Technical parameters

| Model | BOSM-1000 | |

| Maximum processing workpiece saizi | Inobvumidzwa yakanyanya kutenderera dhayamita yeworkpiece (mm) | ≤Φ2000 |

|

Worktable | Dimensions of worktable (mm) square | □1000 |

| Dimensions of worktable (mm) round | Φ1200 | |

| Horizontal maximum load (kg) | 5000 | |

|

Vertical Ram Drilling Unit | mari) | 1 |

| Spindle taper | BT50 | |

| Kuchera dhayamita (mm) | 2-120 | |

| Milling cutter disc dhayamita (mm) | 200 | |

| Kubata dhayamita (mm) | M6-M36 | |

| Distance kubva kuspindle end face kusvika patafura centre (mm) | 1000-1600 | |

| Distance kubva kuspindle centre kuenda kumusoro kwetafura (mm) | 100-1100 | |

| Spindle kumhanya (r/min) | 30-3000 | |

| Spindle mota simba (kw) | 30 | |

| Workpiece axis inotenderera (A axis) | Nhamba huru yekuparadzanisa (mm) | 360° |

| Isa iyo shoma yekuparadzanisa unit | 0.001° | |

| A-axis servo mota simba (kw) | 4.2 | |

| Musoro wesimba unofamba kuruboshwe uye kurudyi (X axis) | Kunyanya sitiroko (mm) | 2000 |

| X-axis inofamba kumhanya (m/min) | 0~8 | |

| X-axis servo mota simba (kw) | 2.4 | |

| Musoro wesimba unokwira nekudzika (Y axis) | Kunyanya sitiroko (mm) | 1000 |

| Y-axis inofamba kumhanya (m/min) | 0~8 | |

| Y-axis servo mota simba (kw) | 2.4 Mabhureki | |

| Column longitudinal movement (Z axis) | Kunyanya sitiroko (mm) | 600 |

| Z-axis inofamba kumhanya (m/min) | 0~4 | |

| Z axis servo mota simba (kw) | 2.4 | |

| Positioning kururama | 1000mm | ±0.05 |

| Kudzokorora | 1000mm | ±0.025 |

| CNC indexing tafura indexing kunyatsoita (mm) |

| 15” |

| Machine dimensions (kusanganisira kudzivirira) | Kureba (X) × Kufara (Z) × Kureba (Y) (mm) | 约 5300*6000*3400 |

| Gross huremu (t)kusanganisira dziviriro | (inenge) 20 | |