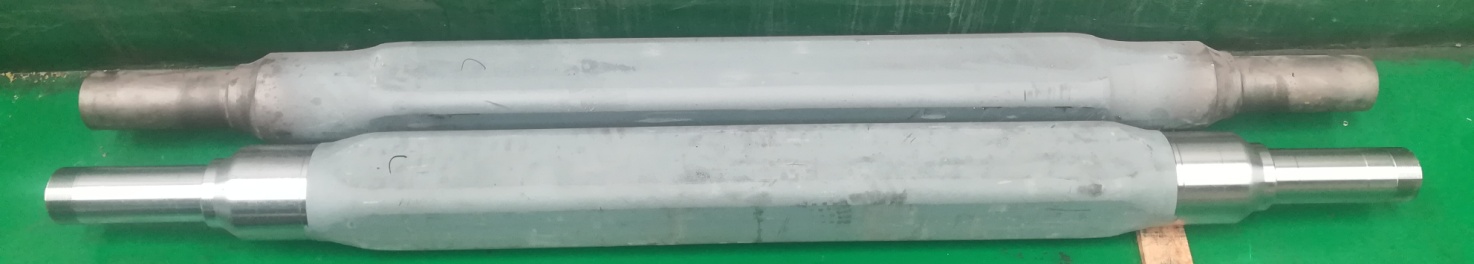

Maekisi ane mavhiri pamativi ese eiyo undercarriage (frame) akaunganidzwa anonzi maekisi emota, uye maekisi ane kutyaira anowanzo kunzi ma axles. Musiyano mukuru pakati pezviviri izvi ndewekuti kune dhiraivha pakati peekisi (axle). Mubepa iri, axle yemotokari ine dhiraivha unit inodaidzwa kunzi mota isina dhiraivha inodaidzwa kuti axle yemotokari kuratidza mutsauko.

Nekuwedzera kuri kuita kudiwa kwezvinhu uye zvekufambisa, hukuru hwema axles emota, kunyanya matrailer uye semi-trailer, mukufambisa kwehunyanzvi uye mashandiro akasarudzika ari kuramba achijeka, uye kudiwa kwemusika kwakawedzera zvakanyanya.

Iyi tekinoroji inoongorora machining maitiro eiyo axle, tariro yekubatsira vatengi kuti vasarudze akakodzera CNC muchina.

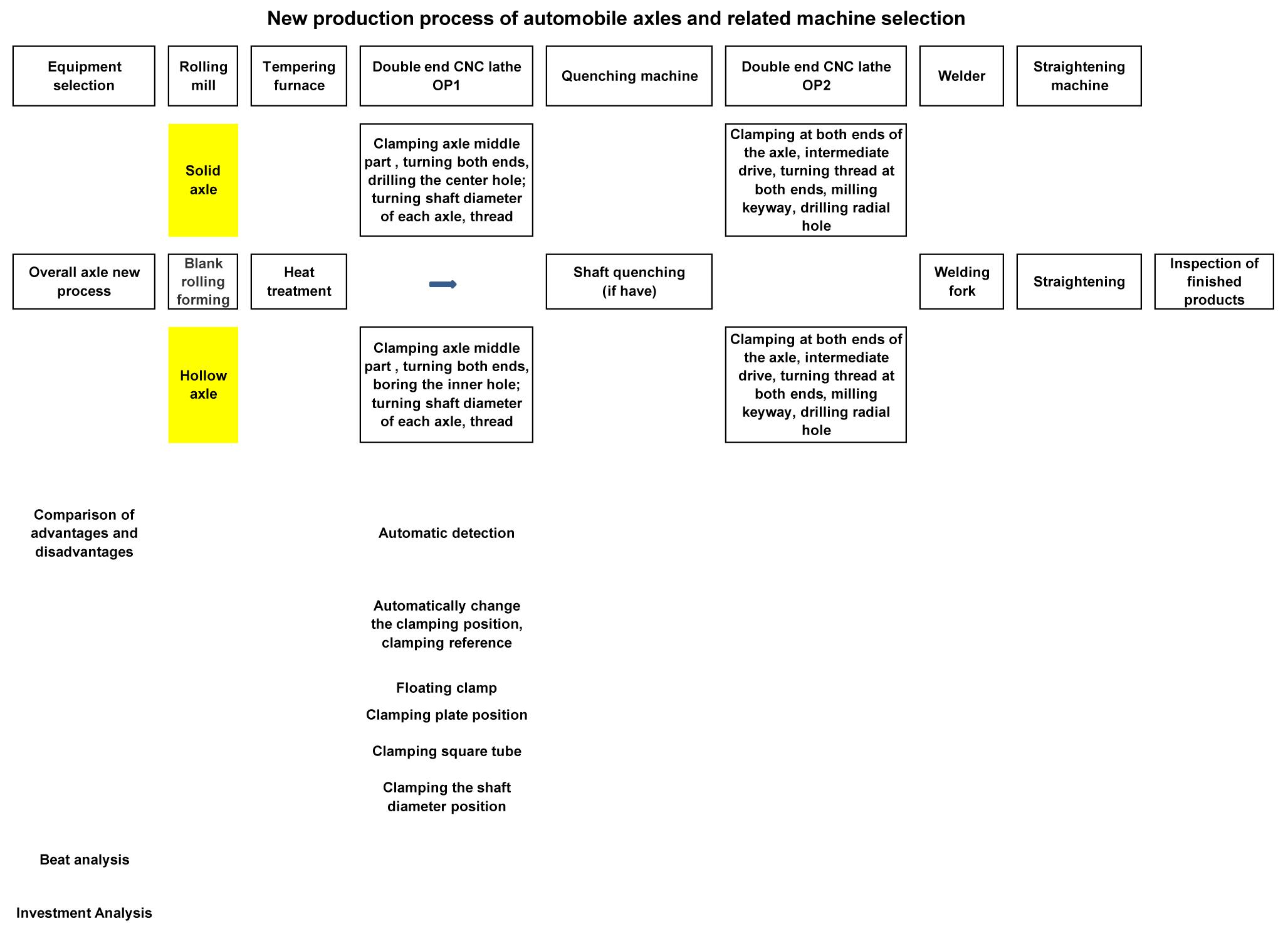

Iyo nyowani yekugadzira maitiro emota yakazara axle:

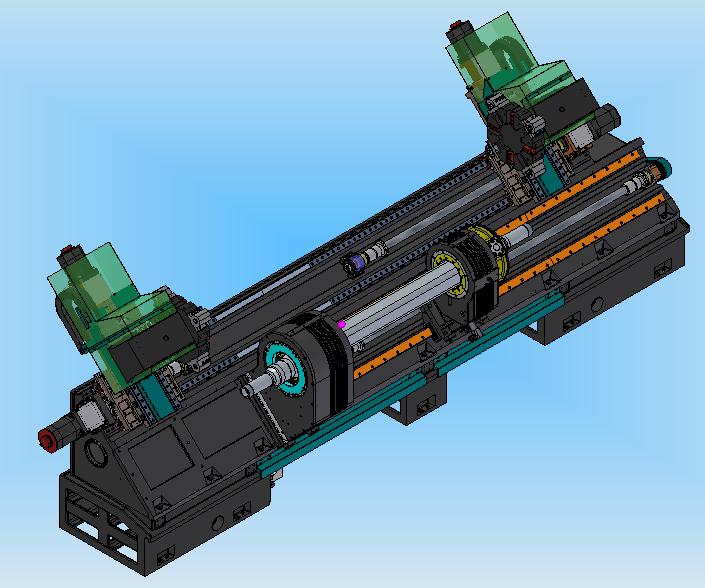

Kubva pamaitiro matsva ekugadzira, muchina wekugaya unoshandiswa kugadzira (solid axle) kana kaviri-sided boring muchina (hollow axle) pamwe neCNC lathe, yechinyakare OP1 milling, OP2, OP3 inotenderedza kutevedzana, uye kunyangwe OP5 kuchera uye kugaya Inogona kutsiviwa. neaviri-magumo CNC lathe OP1.

Kune maekisi akasimba uko shaft dhayamita isingade kudzimwa, zvese zviri mukati memuchina zvinogona kupedzwa mune imwe setup, kusanganisira milling kiyi grooves uye kuchera radial maburi. Kune maaxles asina mhango uko iyo shaft dhayamita isingade kudzimwa, iyo otomatiki inoshandura clamping standard inogona kuwanikwa mumuchina wemuchina, uye machining emukati anogona kupedzwa nechishandiso chemuchina mumwe.

Sarudza kaviri-yekupedzisira axle yakakosha CNC lathes kumashini maaxles anopfupisa nzira yekugadzira, uye mhando uye huwandu hwematurusi emuchina akasarudzwa achaderedzwawo.

Kubatsira uye chimiro chemushini mutsva wekusarudza maitiro:

1) Kuisa pfungwa kweiyo maitiro, kuderedza nguva dze workpiece clamping, kuderedza yekubatsira yekugadzirisa nguva, uchishandisa panguva imwe chete yekugadzira tekinoroji kumigumo yese, kugadzirwa kwakanaka kunovandudzwa zvakanyanya.

2) Imwe-nguva yekurovera, panguva imwe chete kugadzirisa pamigumo yese inovandudza machining iko uye coaxiality yeaxle.

3) Kupfupisa maitiro ekugadzira, kuderedza kutendeuka kwezvikamu panzvimbo yekugadzira, kunatsiridza kugona kwekushandiswa kwesaiti, uye kubatsira kuvandudza sangano uye manejimendi ekugadzira.

4) Nekuda kwekushandiswa kwemhando yepamusoro-yekugadzirisa michina, inogona kuve yakashongedzerwa nekurodha uye kurodha zvishandiso nemidziyo yekuchengetera kuti iwane zvizere kugadzira otomatiki uye kuderedza mutengo wevashandi.

5) Iyo workpiece inosungirirwa panzvimbo yepakati, iyo clamping yakavimbika, uye torque inodiwa pakucheka kwechishandiso chemuchina yakakwana, uye huwandu hukuru hwekutendeuka hunogona kuitwa.

6) Chishandiso chemuchina chinogona kuve chine otomatiki yekuona mudziyo, kunyanya kune gomo axle, iyo inogona kuve nechokwadi kukora kweyunifomu yeaxle mushure mekugadzira.

7) Kune maekisi maburi, kana maburi emukati kumagumo ese eOP1 sequencer apera, mutengi wechinyakare achashandisa imwe mugumo kusimudza simbi uye imwe magumo kushandisa tailstock kuomesa workpiece kutendeuka, asi saizi ye gomba remukati rakasiyana. Kune diki remukati gomba, kuomesa kusimba hakuna kukwana, torque yekusimbisa yepamusoro haina kukwana, uye kucheka kwakanaka hakugone kupedzwa..

Kune iyo nyowani-yechipiri-yechiso lathe, iyo gomba axle, kana maburi emukati kumagumo ese emota apera, muchina unochinja otomatiki nzira yekubatanidza: iyo miviri migumo inoshandiswa kuomesa workpiece, uye yepakati dhiraivha inoyangarara iyo workpiece. kutumira torque.

8) Iyo headstock ine yakavakirwa-mukati hydraulic clamping workpiece inogona kufambiswa munzira yeZ yemuchina. Mutengi anogona kubata chinzvimbo chepakati square chubhu (yakatenderera chubhu), nzvimbo yepasi ndiro uye shaft dhayamita yenzvimbo yeakisi sezvinodiwa.

Mhedziso:

Tichitarisa mamiriro ari pamusoro apa, kushandiswa kwekaviri-magumo CNC lathes kumashini emota maekisi ane mabhenefiti akakosha pane echinyakare maitiro. Iyo tekinoroji yepamberi yekugadzira iyo inogona kutsiva yechinyakare muchina maturusi maererano nemaitiro ekugadzira uye muchina chimiro.

Nguva yekutumira: Mar-15-2021