TheSpecial Valve Machineinonyanya kushandiswa mukugadzira Valve (Butterfly vharafu / Gedhi vharafu / Bhora vharafu / globe vharafu, nezvimwewo ..), Pombi muviri, Auto zvikamu, Kuvaka muchina zvikamu etc.

Inoshanda kune akawanda akasiyana magadzirirwo, akadai se: Kuguma kumeso, denderedzwa rekunze, kumucheto kwemberi, Inner gomba, grooving, Screw thread, Bore-gomba uye Sphere. Inogona kuona otomatiki, kunyatsojeka, kwakasiyana-siyana uye kugadzirwa kwakawanda. Inoshandiswa zvakanyanya muindasitiri yevharuvhu.

About theindasitiri yevharuvhu

Mavharuvhu zvishongedzo zvepombi zvinoshandiswa kuvhura nekuvhara mapaipi, kudzora kuyerera, kugadzirisa uye kudzora ma paramita (tembiricha, kudzvanywa, uye kuyerera) kwesvikiro rekufambisa. Zvinoenderana nebasa rayo, inogona kukamurwa kuita yekuvhara-vhavha,cheki vharafu, vharafu inogadzirisa, zvichingodaro.

Ivhavha inhengo yekutonga mumagetsi ekufambisa. Iyo ine mabasa ekucheka-kubvisa, kudzora, kuchinjisa, kudzivirira reverse kuyerera, kudzikamisa, kutsauka kana kufashama, uye kudzoreredza kudzvinyirira. Mavharuvhu anoshandiswa mumagetsi ekudzora masisitimu, kubva kune akareruka-akavhara mavharuvhu kusvika kune akasiyana mavharuvhu anoshandiswa muakaomesesa otomatiki kudzora masisitimu, ane huwandu hwakawanda hwemhando uye zvakatemwa.

Mavharuvhu anoshandiswa zvakanyanya munzvimbo dzakasiyana siyana. Kunyanya peturu, simbi, simba remagetsi, kuchengetedza mvura, kuvaka kwemadhorobha, kudzima moto, michina, marasha, chikafu, nezvimwe.

Kuwanikwa

Ndezvipi zvakanakiraSpecial Valve Machinemuindasitiri yevharuvhu

√Kuchera kunotora mhando ye-multi-axis, uye kushanda kwayo kunovandudzwa kakawanda.

√Shandisa misoro miviri kana mitatu panguva imwe chete panguva yekugadzirisa kuti uone kumira uye kushanda kwepamusoro kwepombi pombi vharafu kugadzirisa.

√Exclusive patented manhamba control system, yakazara otomatiki mashandiro.

Yedu yakakurudzirwa Special Valve Machine

Mazano edudSpecial Valve Machine

1.Muviri muviri

Muviri weMuchina wakagadzirwa nehupamhi hwepamusoro-mhando yegrey iron cast, hutsinye machining, kupedzisa, uye matatu anopisa kurapa kuchembera kuti abvise zvachose kushushikana kwasara. Pamusoro penzira yekufambisa

Iyo inotora super-audio frequency quenching kurapwa uye inogadziriswa nepamusoro-chaiyo gwara renjanji kugaya kuti ive nechokwadi chekurongeka, kusimba, uye kugadzikana kwemuchina chishandiso. √

2.Special Valve Machine

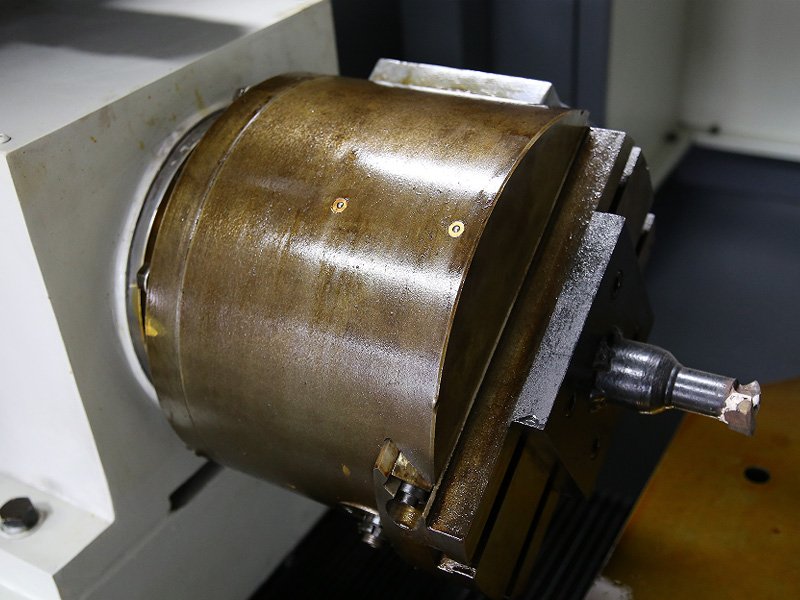

Musoro Bhokisi

Bhokisi reMusoro rakagadzirwa nepamusoro-soro castings, uye shaft huru inogadzirwa ne20GrMnTAi, iyo yakave yakagadziriswa, yakadzimwa, uye yakanyanyisa, carburized uye inodzimwa, uye yakawedzerwa nepamusoro-soro mukati uye kunze kwe cylindrical grinder.

Iyo inotakura inotora yakakwirira-chaiyo mbiri-mutsara cylindrical roller mabheji kuti ive nechokwadi chekuomarara uye kunyatsojeka kweiyo spindle. Iyo huru shaft inotora matatu-nhanho yekumhanyisa shanduko ine yakakwirira-simba mota kuti iwane yakaderera kumhanya

Yakakura torque, inogona kutakura mutoro unorema wekucheka, kuvandudza mashandiro ekugadzirisa. √

7. Centralized lubrication mudziyo

Iyo lubrication system yakashongedzerwa neNanjing Beqier inofambira mberi lubrication mudziyo, iyo inogara ichipomba mafuta ekuzora munzvimbo yekuzora yeimwe neimwe inofamba, ichibvisa inonetesa mashandiro ebhuku.

Kuvandudza hupenyu hwesevhisi yemuchina wekushandisa. √

Misoro miviri CNC Machine

Butterflyvharafu yakakosha muchina

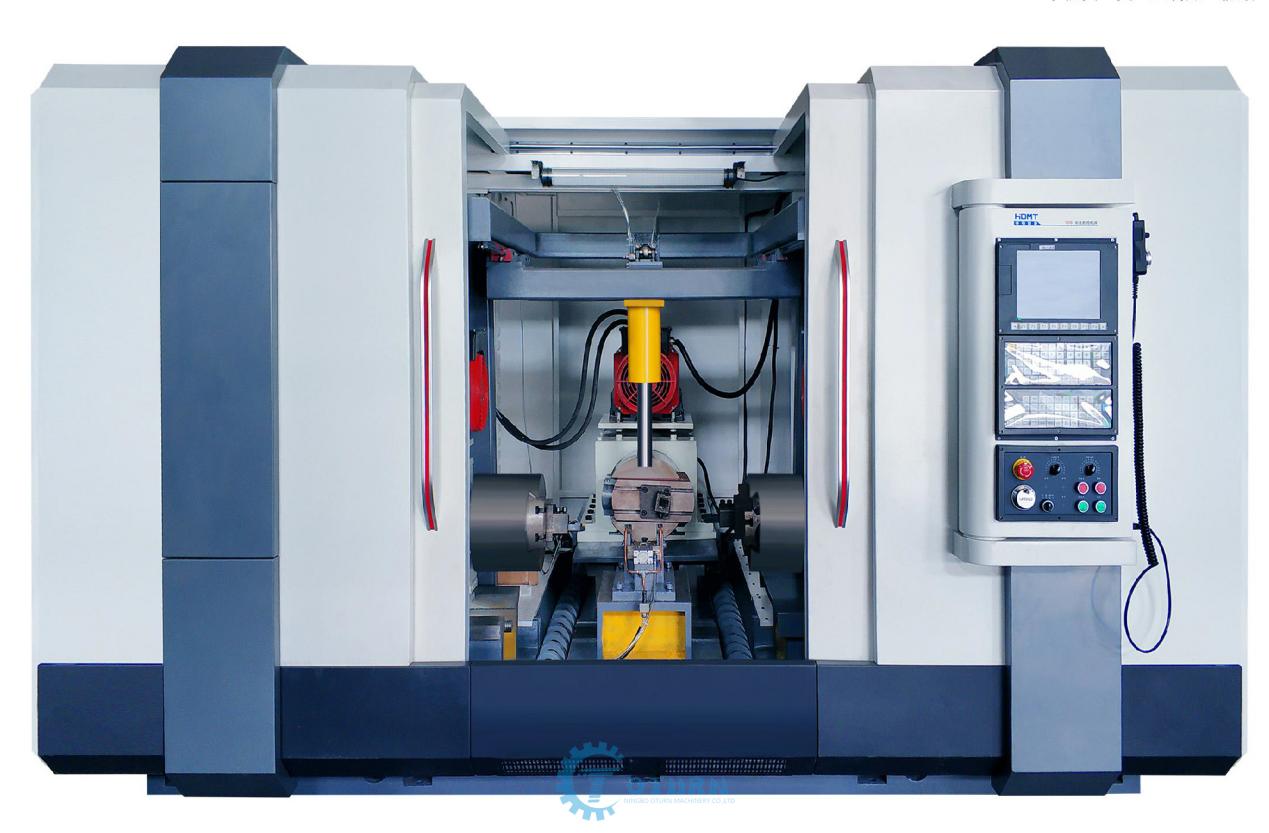

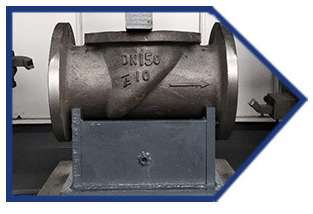

HDCX800 inoshandura-milling composite machining centre,butterfly valvespecial processing machine tool inonyanya kushandiswa mumashavishavi mavharuvhu uye zero

Kugadziriswa kwezvikamu, mainjiniya einjiniya uye zvimwe zvikamu, iyo yekupedzisira kumeso, denderedzwa rekunze, spigot, gomba remukati, groove, shinda, taper gomba uye spherical chimiro cheworkpiece inogona kugadziriswa.

Kutendeuka. Maitiro ekugadzirisa anodzorwa neiyo GSK CNC system, iyo inogona kuona otomatiki, yakakwira chaiyo, yakawanda-siyana, uye kugadzirwa kwakawanda.

main feature

1. Iyo HDCX800 Special Valve Machine inodzorwa neiyo GSK CNC system, iyo inogona kuwanikwa ne-dual-axis linkage.

Kugadziriswa kwematepi maburi, shinda, uye spherical process. Yayo CNC sisitimu inowirirana, ine simba, uye iri nyore kushanda.

2. Iyo inotungamira njanji yefeed slide inogadzirwa neyemhando yepamusoro grey cast iron, iyo yakave pasi pehutatu hunotyisa kurapwa kwekuchembera mushure me roughcasting uye kupedzisa kubvisa zvizere kusara kwemukati kushushikana.

Iyo yepamusoro inotora super-audio frequency quenching kurapwa uye kuoma kunosvika HRC55. Iko kurongeka, kusimba, uye kugadzikana kwechishandiso chemuchina unovimbiswa nepamusoro-chaiyo njanji kugaya.

.

4. Musoro wesimba unotora matatu-nhanho manual transmission ne-high-power motor kuti iwane yakaderera-speed uye yakakwirira-torque, inogona kumira mitoro inorema yekucheka, nekuvandudza kugadzirisa kushanda.

5. Chishandiso chinotora hydraulic otomatiki clamping kuvandudza kugona uye kuderedza basa remunhu.

6. HDCX800 Special Valve Machine,butterfly vharafu yakakosha yekugadzirisa muchinachishandiso chinotora mafuta epakati kuti ive nechokwadi chekuti chikamu chimwe nechimwe chinofamba chakazara mafuta uye kugadzirisa muchina chishandiso.

Special Valve Machine Chimiro

Power Head

Iyo simba headbox body inogadzirwa nemhando yepamusoro castings, uye shaft huru inogadzirwa ne20GrMnTAi zvinhu, iyo inogadziriswa nekugadzira, kudzima, uye kupisa, carburizing, uye kudzima, uye yakakwirira-chaiyo yemukati nekunze cylindrical grinders.

Iyo inotakura inotora NN30 yakatevedzana yakakwirira-chaiyo mbiri-mutsara cylindrical roller mabheji kuti ive nechokwadi chekuomarara uye kunyatsojeka kweiyo spindle.

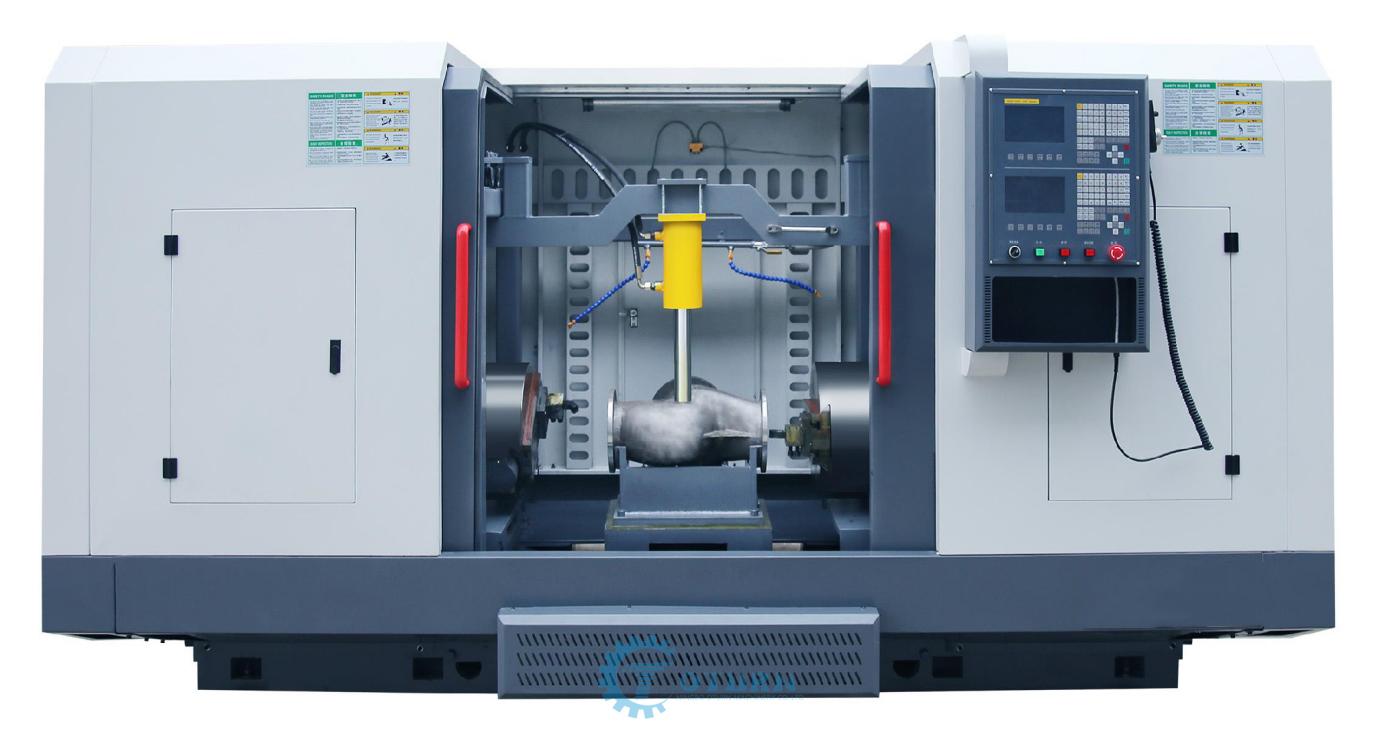

Worktable

Iyo worktable ndeye yakakosha workbench yakanyatso kugadzirirwa zvinoenderana neakagadziriswa zvikamu. Iwo mabhuraki ekumisa uye mapini ekumisikidza ese anodzimwa kuti ave nechokwadi chekumisikidzwa kwakavimbika kweiyo workpiece.

Workpiece clamping inotora manyore clamping kuti ivandudze mashandiro ekugadzirisa uye kuderedza basa remunhu. Uye iyo worktable inogona kutenderedzwa 180 madhigirii, imwe-nguva clamping, imwe-nguva Pedzisa maitiro ese.

Otomatiki chishandiso chekushandura chishandiso magazini

Fully automatic CNC tool change tool magazine, inogona kubata maturusi gumi nematanhatu, maturusi makumi maviri, maturusi makumi maviri nemana, zvichingodaro, ayo anodzorwa otomatiki nehurongwa, nekutsanya kwechishandiso chekuchinja nekukurumidza uye kunyatsoita.

- Simba musoro

Musoro wesimba unotora yakasarudzika patented motor + screw chimiro, iyo ine hunhu hwepamusoro kunyatsojeka, kusimba kwepamusoro, uye hupenyu hwakareba.

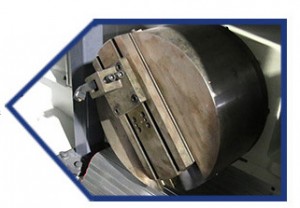

- Tooling

-

Iyo yekushandisa ndeye yakakosha tooling yakanyatso gadzirwa zvinoenderana nezvikamu zvinofanirwa kugadziriswa. Iwo mabhuraki ekumisa uye mapini ekumisikidza ese anodzimwa kuti ave nechokwadi chekumisikidzwa kwakavimbika kweiyo workpiece. Iyo workpiece inosungirirwa ne hydraulic clamping, iyo inovandudza mashandiro ekugadzirisa uye inoderedza kusimba kwevashandi.

- Magetsi cabinet

Iyo kabati yemagetsi inotora yakazvimirira yakavharwa mhando, ine yakavakirwa-mukati control system, frequency converter uye airport control yemagetsi zvikamu, uye yakashongedzerwa nemhepo-inotonhorera zvishandiso kuti ive nechokwadi chekuti zvikamu zvemagetsi zvemuchina wemuchina zvinoshanda zvakajairwa uye hazvipinde muguruva.

- CNC Control System

Iyo ine mabasa e-multi-channel control tekinoroji, mashanu-axis machining, yakakwirira-kumhanya uye yakakwirira-chaiyo, kutendeuka uye kugaya, synchronous control uye mamwe akakwira-magumo CNC control.

Kusarudzwa kwemidziyo:

CNC kutonga

kutonhora kuzvidzora

Otomatiki chip conveyor

Kudzivirirwa kwehafu / kuchengetedzwa kwakazara

Kune marudzi akasiyana-siyana evhavha, maitiro akasiyana anogadziriswa. Semuyenzaniso, mabasa ekugadzira uye kwakasiyana gadziriro yehunyanzvi inofanirwa kuitwa isati yagadziriswa. Mainjiniya anofanirwa kuita gadziriro dzakakodzera zvinoenderana nemagadzirirwo echigadzirwa pachayo uye yakakosha magadzirirwo emidziyo yekugadzira ndege yeHuadian valve. Ivhavha isina chinhu zvikamu zvinogona kugadzirwa nekukanda jecha, kukanda chaiko kana museve kukanda wakisi pakugadzira. Zvekugadzira kana welding maitiro, zvinodikanwa kugadzira zvinoenderana neakakodzera asina chinhu mamiriro.

Thevalve processing proceduresdzakaoma, uye kukosha kwakawedzerwa kwechigadzirwa kwakaderera. Zvakanakira kushandisa general-chinangwa kanaCNC muchina zvishandisohaigone kuratidzwa. Kugadziriswa kwakazara kwevhavha kunotoda kusanganiswa kwemichina yakawanda kuti uwane iyo yekugadzirisa maitiro. Pese paunochinja saizi kana siyana, unofanirwa kugadzirisa chishandiso chemuchina, uye wobva waendesa maitiro apera kubva kune yakapfuura maitiro kuenda kune inofananidzwa muchina chishandiso mune inotevera maitiro. Izvi hazvisi kungowedzera mutengo wekugadzira, asiwo zvinoparadza mari yakawanda yenguva. Kazhinji, maworkpiece anoda kurongeka kwepamusoro, nekuda kwekuchinja kwakawanda kwekurovera, wedzera kukanganisa chaiko kweiyo workpiece. Saka zvikomborero zvendege yevharuvhuzvinobuda pachena.

Somuenzaniso, nokudagedhi mavharuvhu, kutendeutsa kwemativi matatu-mativi flanges kunogona kuitwa pamushini mumwe chete. Parizvino, iyo HDMT valve yakakosha muchina unogona panguva imwe chete mativi maviri kana matatu evhavha flange panguva imwe, iri nyore uye inoshanda, nepo kugadzirwa kwechinyakare Imwe chete flange yevhavha inogona kugadziriswa panguva, iyo inopedza nguva. uye kushanda nesimba. Nenzira imwecheteyo, kuchera flange pamativi matatu kana maviri evhavha kunobvawo pamutemo wakafanana, izvo zvisingangogadziri kushanda zvakanaka, asiwo zvinoderedza kushivirira kwechinzvimbo chegomba.

Kushanda kwevharafu yakakosha muchinazvakare iri nyore kwazvo, ese mamodheru akaziva iyo otomatiki dhizaini, inongoda kuisa ma paramita. Izvi zvinoderedza zvakanyanya mashandiro emawoko, zvinoderedza mutengo wevashandi, uye zvinochengetedza nguva nesimba. Kana paine kuwandisa kana rimwe dambudziko rikaitika panguva yekugadzira, muchina unobva wapa alarm kana kudzima otomatiki, kuitira kudzivirira kukuvara kwemuchina kusvika pamwero mukuru.

Mushure mekunge ndege yevharuvhu yapera, mushandisi anofanira kudzima magetsi anoenderana, kuita basa rakanaka rekuchenesa, uye kushandisa mafuta ehunyanzvi kugadzirisa uye kuchengetedza ndege yevharuvhu. Pane zvinhu zvakawanda zvinoda kutariswa panguva yekushanda kweiyo yakakosha valve muchina. Iyo yakakosha yevhavha muchina haigone kuita mabasa akadai sekugadzirisa chishandiso, kuongorora uye kubviswa panguva yekushanda. Munguva yese yekushanda kweiyo yakakosha valve muchina, vashandi vakakodzera nevashandisi havafanirwe kusiya mabasa avo, uye vanofanirwa kuita basa rakanaka rekutarisa kwakakodzera. Zvishandiso zvakaita semaworkpiece, zvigadziriso, uye mapanga zvinofanirwa kusungirirwa zvakasimba, zvikasadaro mamwe matambudziko nekufamba kweworkpiece achaitika. Kusashanda zvakanaka kunogona kukonzera kukuvara kusingakoshi. Kana banga rikatyoka kana kutyoka, rinoda kuchinjwa nenguva. Mukuita kwekushanda kwemazuva ose, hatigoni kubata zvakananga pamusoro pebasa rekushanda nemaoko edu, uye hatigoni kubvisa zvakananga zvinhu zvine ngozi zvakadai sekucheka nemaoko edu. Izvi hazvizongokuvadza maoko edu chete, asiwo zvinokonzera kuti mapepa esimbi abhururuke. Tsaona mumaziso. Munguva yekushanda kwendege yakakosha yevharuvhu, unofanira kupfeka hovhorosi dzinoenderana, pfeka chivharo chebasa, uye iva nechokwadi chekuisa bvudzi rako muvharo yebasa. Paunenge uchirodha uye uchiburitsa mahombe ekushanda, edza kushandisa midziyo yekusimudza, kuitira kuti basa rese rigone kugarisana nehunyanzvi, uye kuchengetedzwa kwekuita kuchave kwakakwira.

Nguva yekutumira: Sep-22-2021