Inguva yekutanga kuti vatengi mune mamwe matunhu akakosha kusangana nawoCNC lathes, uye kushanda kweCNC lathes haisati yakwanisa kugona hunyanzvi hwekushandisa muchina chete kubva mukutungamira kwebhuku rekushandisa. Kubatanidza ruzivo rwekushanda rwakaunganidzwa nevane ruzivoChina CNC lathevashandi mubasa ravo rezuva nezuva, ini ndichatsanangura unyanzvi hwekugadzirisa zvishandiso uye matanho ekugadzirisa ezvimwe zvikamu.

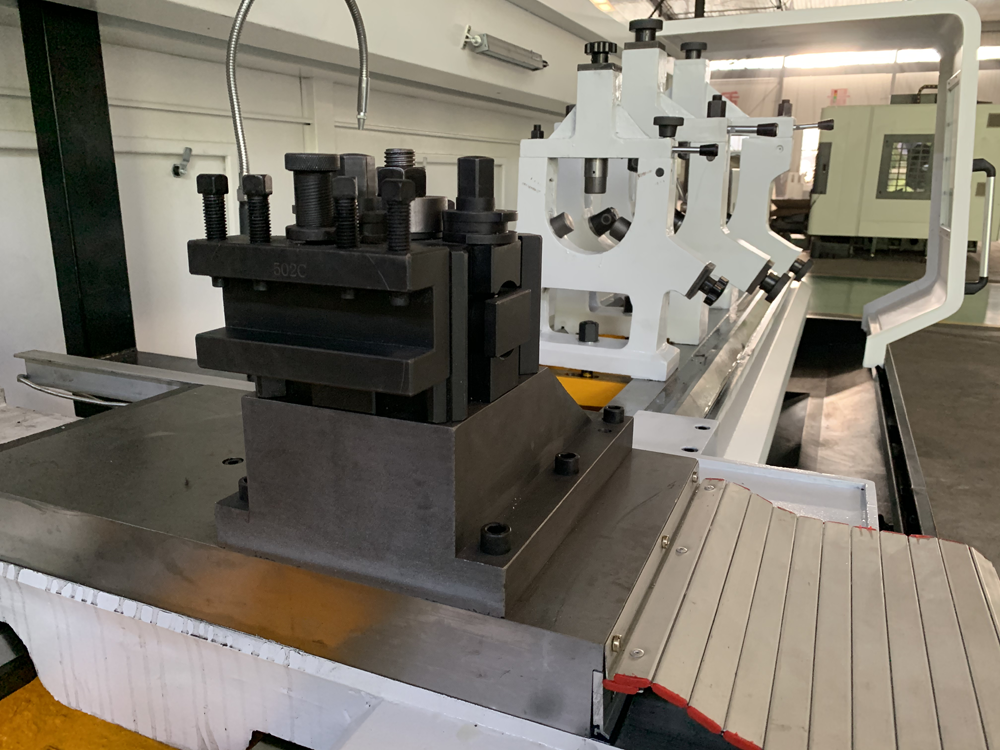

Iyo nzira uye hunyanzvi hwekumisikidza maturusi muindasitiri yemuchina inogona kukamurwa kuita mapoka maviri: yakananga maturusi kugadzika uye mudziyo wekushandisa. Pamberi peCNC lathe inodzokera kunzvimbo yekutanga, yegakutendeuka zvakarel iyo inoda kushandiswa inoiswa nepakati poindi yerudyi rwekugaya chiso chechikamu se 0 poindi, uye ipapo nzvimbo yepakati yeiyo yekurudyi inotendeuka chiso chechikamu inosarudzwa se 0 point uye iyoCNC chishandisopoint is set. Kana chishandiso chekushandura chabata iyo yekurudyi yekugaya kumeso kiyibhodhi, isa Z0 uye tinya kuti uone, iyo yekutsinhanisa kukosha kwechishandiso chekushandura inongochengetedza iyo data yaonekwa, zvinoreva kuti iyo Z-axis chishandiso chapedzwa, uye X chishandiso kuseta. ndiyo yekuyedza yekucheka chishandiso kuseta, uye chigayo chekucheka chinoshandiswa Denderedzwa rekunze rezvikamu zvemotokari ishoma, uye data rekunze redenderedzwa remota yakaonekwa (senge x iri 20 mm) keyboard yekuisa x20, tinya kuti uone, chishandiso. Mari yekubhadhara inongochengetedza iyo data yakaonekwa, panguva ino iyo x-axis inopedzwawo.

Iri rudzi rwechishandiso chekumisikidza nzira, kunyangwe iyoCNC latheyapera simba, kukosha kwechishandiso hakuzoshandurwe mushure mekunge simba ratangwazve. Inogona kuiswa kune batch yenguva refu kugadzirwa uye kugadziriswa kwezvikamu zvakafanana. Munguva iyi, muchina haudi kudzokororwa zvakare kana muchina wavharwa.

(1) Pinda tanga wozopedzisira wati sandara (izvi ndezvekudzivisa shrinkage kana uchibaya).

(2) Kutendeuka kwakakasharara kutanga, wozonyatso pinduka (izvi ndezvekuona kurongeka kwezvikamu).

(3) Kutanga gadzira iwo ane maburi mahombe uye wozoita iwo ane maburi madiki (izvi ndezvekuona kuti kunze kweiyo diki gap size haina kukweshwa uye kudzivirira zvikamu kukanganisa).

(4) Sarudza iyo chaiyo yekumhanyisa reshiyo, kucheka huwandu uye kudzika kwekucheka zvinoenderana neyakaomarara zviyero. Iyo kabhoni simbi yeplate zvinhu inosarudzirwa yakakwirira-kutenderera kutenderera, yakakwirira yekucheka kugona, uye yakakura yekucheka kudzika. Zvakadai se: 1Gr11, shandisa S1 600, F0.2, uye cheka kudzika 2 mm. Iyo alloy inoshandisa yakaderera kumhanya ratio, yakaderera chiyero chekudya uye kudzika kudiki kwekucheka. Zvakadai se: GH4033, sarudza S800, F0.08, uye cheka kudzika 0.5mm. Titanium alloy simbi inosarudza yakaderera kumhanya ratio, yakakwirira yekucheka kugona, uye kudzika kudiki kwekucheka. Zvakadai se: Ti6, shandisa S400, F0.2, uye cheka kudzika 0.3mm. Tora kugadzirwa kwechimwe chikamu semuenzaniso: zvinhu iK414, inova yakawedzera-yakaoma zvinhu. Mushure mekudzokororwa bvunzo, yekupedzisira kusarudzwa iS360, F0.1, uye kudzika kwekucheka 0.2, zvikamu zvakajairwa zvisati zvagadzirwa. (Izvi ndezvekutarisa chete, ndapota ita zvigadziriso chaizvo zvichibva pane-saiti muchina paramita, zvinhu, nezvimwe kune chaiwo mamiriro!)

Nguva yekutumira: Nov-29-2021