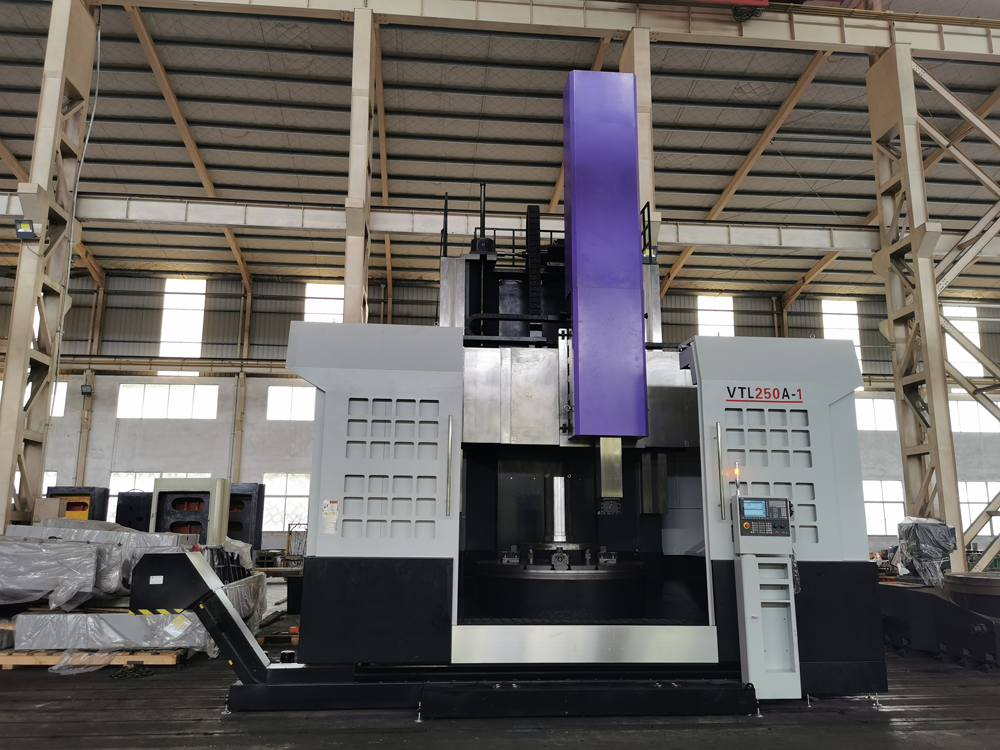

Zvikuru-zvikuruCNC vertical lathesmichina mikuru-yakakura, iyo inoshandiswa kugadzirisa mahombe uye anorema maworkpiece ane mahombe eradial dimensions uye madiki axial dimensions, uye maumbirwo akaomarara. Semuenzaniso, iyo cylindrical pamusoro, pekupedzisira pamusoro, conical pamusoro, cylindrical gomba, conical gomba reakasiyana madhisiki, mavhiri uye seti yezvishandiso zvebasa zvinogonawo kugadziriswa nerubatsiro rwezvimwe zvigadziriso zvekugadzira, spherical surface, profiling, milling uye kugaya.

Nguva yekubatsira yehukuru-hukuruCNC VTL Machineipfupi kwazvo. Inogona kupedzisa zvese zvekugadzirisa zvirimo mune imwe clamping. Edza kusarudza chigadziro chakazaruka nehupamhi hwepamusoro, iyo isingagoni kukanganisa nzira yezvishandiso, uye inogona kupedzisa kugadziriswa kwechigadziro chekushanda mukati mehutano hwe spindle sitiroko. Sechishandiso chemuchina wemuchina, maalarm akasiyana achaonekwa mushure menguva yekushandiswa. Zvimwe ndezvekutadza kwehurongwa, zvimwe zvigadziriso zvisina kufanira, uye zvimwe kutadza kwemagetsi. Fani maalarm ndeimwe yacho.

Kana mamiriro akadai akaitika, tarisa fan yemukati kutanga. Kana isingatendeuki, ibvisei muone; Kana yakanyanya kusvibiswa, pukuta nedoro kana peturu usati waiisa. Kana paine alarm, unofanirwa kutsiva iyo servo amplifier. HC inooneka. Alarm yazvino, kunyanya kuona yakashata padivi reDC, tanga watarisa servo paramita, wozobvisa tambo yemagetsi. Munguva iyi, pane alarm yekutsiva servo amplifier. Hapana alarm. Chinjana mota uye tambo yemagetsi neimwe axis kuti uone kana iri mota kana tambo yemagetsi. Dambudziko: Kana J ikaonekwa pachiratidziro, zvinoenderana nekuti idambudziko rePC. Tarisa uone kana iyo mamaboard, interface yekushandura bhodhi uye PCRAM yekudzora bhodhi mudziyo wakarurama, tsiva uye gadzirisa kusvika chikonzero chatemwa, wozogadzirisa dambudziko.

Kana mamiriro akadai akaitika, tarisa fan yemukati kutanga. Kana isingatendeuki, ibvisei muone; Kana yakanyanya kusvibiswa, pukuta nedoro kana peturu usati waiisa. Kana paine alarm, unofanirwa kutsiva iyo servo amplifier. HC inooneka. Alarm yazvino, kunyanya kuona yakashata padivi reDC, tanga watarisa servo paramita, wozobvisa tambo yemagetsi. Munguva iyi, pane alarm yekutsiva servo amplifier. Hapana alarm. Chinjana mota uye tambo yemagetsi neimwe axis kuti uone kana iri mota kana tambo yemagetsi. Dambudziko: Kana J ikaonekwa pachiratidziro, zvinoenderana nekuti idambudziko rePC. Tarisa uone kana iyo mamaboard, interface yekushandura bhodhi uye PCRAM yekudzora bhodhi mudziyo wakarurama, tsiva uye gadzirisa kusvika chikonzero chatemwa, wozogadzirisa dambudziko.

Ndezvipi zvinhu zvinoda kutariswa mukuchengetedza hombe CNCVTL Machining?

1. Mushure mekutanga motokari huru nguva imwe neimwe, spindle haigoni kutangwa pakarepo. Chete mushure mekunge pombi yekuzora yave kushanda zvakajairwa uye hwindo remafuta rauya nemafuta, spindle inogona kutangwa kurega muchina wekushandisa.

2. Iyo screw inogona kushandiswa chete kana uchitenderedza tambo kuti ive nechokwadi chekururama kwayo uye hupenyu.

3. Chengetedza mukati nekunze kwemuchina mudziyokuti ive yakachena, zvikamu zvemuchina zvakakwana, ma screw rods nemaporishi akakwenenzverwa hazvina oiri, uye nzvimbo dzenjanji dzakachena uye dzakasimba.

4. Ita basa rekuzora renzvimbo yega yega yekuzora zvinoenderana nezvinodiwa (ona iyo label mirairo yemuchina wekushandisa lubrication system kuti uwane ruzivo).

5. Nguva dzose chengetedza uye gadzirisa kuoma kweV-belt yeCNC vertical lathe.

6. Ngwarira kutarisa mamiriro ekushanda kwepombi yemafuta kuti uone kuti bhokisi remusoro uye bhokisi rekudyisa rine mafuta akakwana ekuzora. Oiri yekuzora mutangi rega rega haifanirwe kudzika kupfuura pakati peiyo yega yega chiyero chemafuta, zvikasadaro mudziyo wemuchina uchakuvadzwa nekuda kwekusagadzikana kwemafuta.

7. Chenesa mafuta sefa yemhangura mesh yemafuta sefa muinopinza yemafuta yebhokisi repadivi pemubhedha svondo rega rega kuti uve nechokwadi chekuti mafuta ekuzora akachena.

8. Kana iyo spindle ichitenderera nekukurumidza, pasina mamiriro ezvinhu iwe unofanirwa kudhonza mubato wekuchinja.

Nguva yekutumira: Nov-24-2021